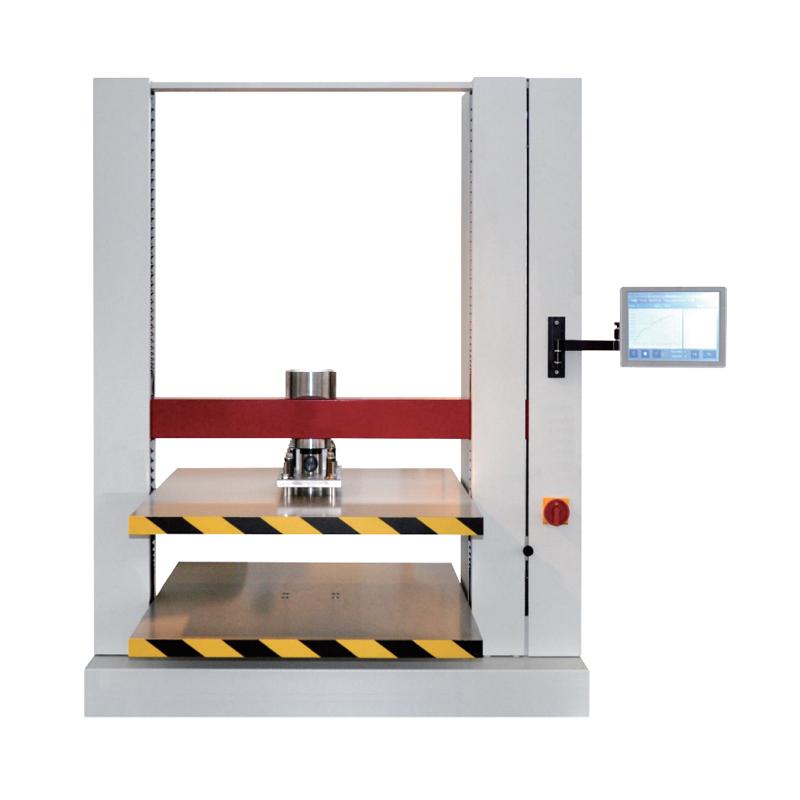

Lambo Huike 19041-8 Carton Compressive Tester Load 10KN

SELabo 19041-8 Compressive TesterSPEC

Labo 19041-8 Compressive TesterDetails

Labo 19041-8 Compressive TesterPacking list

- SKU

- NB031412

- Force range

- 0.2~10KN (1000kg)

- Plate size

- 800*800mm

- Dimensions

- 800*1200*1400mm

- Force Resolution

- 1N

- Error of indication

- ±1%

- Indication of variability

- ≤1%

- Zero Return Error

- ±0.1%FS

- deformation error

- ±1mm

- Stacking test Preset load Relative fluctuation

- ±2%

- Pressurization speed

- 1~300mm/min

- Pressurization speed relative error

- ± 2% (within 1~ 300mm)

- return speed

- 1~300mm/min

- Pressurization speed

- 10mm/min (adjustable)

- Stacking test pressurization speed

- 2mm/min (adjustable)

- Upper and lower platen flatness

- ±0.25mm

- Plate parallelism

- ≤1.5mm

- Working Travel

- 800mm

- test space

- 800*800*800mm

Introduction

It is used to test the compressive strength test of cartons and other packaging containers and transport packages.

The equipment meets the following three test function requirements:

Compression test : used to determine the ultimate compressive strength of the sample, the testing machine automatically records the maximum pressure value and the compressive deformation of the sample;

Fixed value test : The overall performance of the box can be tested according to the set pressure or deformation, and the necessary test data can be provided for the design and selection of the box;

Stacking test : A certain pressure value is continuously applied to the sample within a specified period of time, which is used to measure the durability of the sample under pressure under simulated packaging, storage and transportation conditions. According to relevant standards, stacking tests under different conditions such as 12 hours and 24 hours can be carried out. The equipment has the functions of test data display, memory storage, statistical analysis and processing, and test report printing.

Features

Using high-precision load cell, the accuracy is controlled at <0.5% when leaving the factory, which is better than ±1% of the ISO standard.

The test is completed automatically. The equipment has the functions of displaying test data, memory storage, analysis, statistical processing and printing test reports, and is easy to operate.

The preset test speed and return speed, as well as the free adjustment of the position of the upper platen, make the test faster and more effective.

The load cell is located on the top and connected to the upper platen. The user or the measurement and calibration department (third party) can easily calibrate the instrument by placing the standard sensor between the upper and lower platens for calibration.

Safety protection measures:

Measurement and control system pressure value overload protection;

Power-off automatic locking transmission device protection;

The pressure value of the sensor is automatically reset to zero display;

After the test is completed, it will automatically return to the initial position;

The test speed and return speed are preset to make the test faster and more effective.

Experiment description

Place the test sample in the center between the upper and lower platens of the testing machine, and then choose one of the methods for testing:

Compression test: set the test speed, pressurize according to the predetermined test speed until the test sample is crushed;

Fixed value test : set the load value or displacement value, pressurize to the predetermined load value or displacement value;

Stacking test : set the predetermined load and time, apply the predetermined load until the test sample is damaged or last until the predetermined time.

Note: It is not recommended to compare the results obtained at other speeds such as 12.5mm/min±12.5mm/min and 10mm/min ± 3mm/min.

For some packages, such as metal drums and wooden boxes, it may be necessary to use lower speeds to prevent the maximum load from exceeding the predetermined load value.

use standard

GB/T6543 "Single and Double Corrugated Boxes for Transport Packaging Appendix D: Calculation Method of Compressive Strength of Corrugated Boxes"

GB/T4857.4 "Basic tests for packaging and transportation packages - Part 4: Compression resistance and stacking test methods using a pressure testing machine"

ISO2872 "Packaging - complete - pressure test of fully loaded transport packages"

ISO2874 "Stacking test with pressure testing machine for transport packages"

Similar products

| model | Force measuring range (KN) | Test effective size (length x width x height) mm | Dimensions (length x width x height) mm |

| 19041-5 | 0.1~5 (500kg) | 500x500x500 | 500x800x1100 |

| 19041-8 | 0.2~10 (1000kg) | 800x800x800 | 800x1200x1400 |

| 19041-10 | 0.5~20 (2000kg) | 1000x1000x1000 | 1000x1500x1600 |

| 19041-12 | 0.5~20 (2000kg) | 1200x1200x1200 | 1200x1700x1800 |

| 19041-15 | 1~50 (5000kg) | 1500x1500x1500 | 1500x2100x2100 |

- 1Importance of Corrugated Box Compression Test

- 2What can the carton compressive strength testing machine do?

- 3How to check the compressive strength of corrugated boxes?

- 4Working Principle and Instrument Structure of Carton Compressive Strength Testing Machine

- 1GB/T 44750-2024《Particle—Measurement of crush strength》

- 2JC/T 2570-2020《Color sand flooring materials》

- 3GB/T 25774.1-2023《Test methods for welding consumables—Part 1: Preparation of deposited metal test pieces and specimens for mechanical properties in steel,nickel and nickel alloys》

- 4GB/T 4857.3-2008《Packaging - Basic tests for transport packages - Part 3:Stacking test methods using a static load》

- 5GB/T 21593-2008《Dangerous goods - Test method for stacking of packaging》

- 6GB/T 21590-2008《Dangerous goods - Test method for stacking of intermediate bulk containers (IBCs)》

- 7GB/T 21583-2008《Dangerous goods - Test method for stacking of large packaging》

- 8GB/T 4857.4-2008《Packaging - Basic tests for transport packages - Part 4:Compression and Stacking tests using a compression tester》

- 9QB/T 1048-2004《Board and carton box-Tester of crush resistance》

19041-8

19041-8