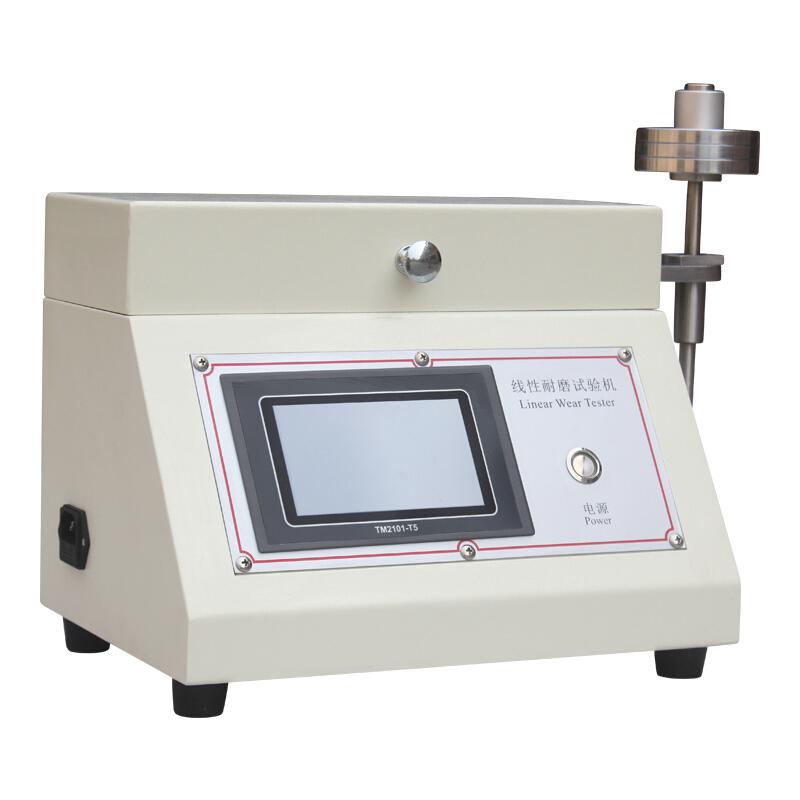

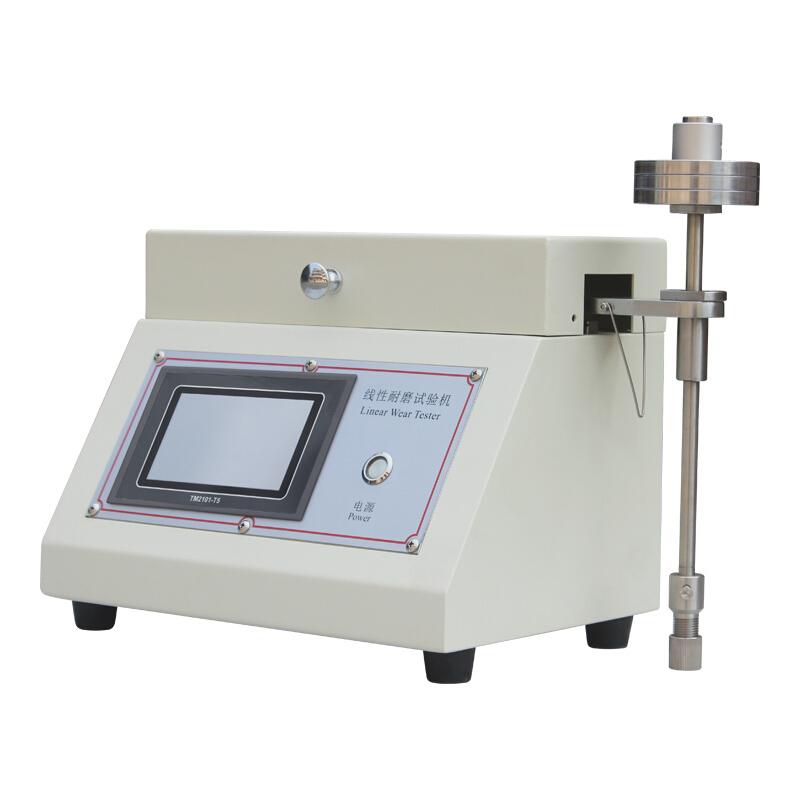

AISRY 5750 Linear abrasion instrument, smart touch screen

AISRY ASR-5750 Linear abrasion instrumentSPEC

AISRY ASR-5750 Linear abrasion instrumentDetails

AISRY ASR-5750 Linear abrasion instrumentPacking list

- SKU

- NB031426

- Friction method

- linear

- Frictional contact form

- point

- Number of grinding heads

- 1

- friction load

- 250gx3

- Rotation speed

- 2~ 60 round trips/minute

- Counting method

- digital display

- test revolutions

- 999

Introduction

Linear wear Testers are used to evaluate the abrasion resistance, scratch resistance (single or multiple scratches) and color transfer (usually friction decolorization resistance or rub fastness) of a product, and can be performed for both dry and wet wear tests.

Apply the object

It can test samples of any size or any shape, and is very suitable for abrasion testing of products with contoured surfaces and polished surface characteristics (e.g. abrasion resistance testing of plastic topcoats for computer mice and other computer or IT products), and is commonly used for plastics, auto parts, rubber, leather and textiles, electroplating, freely disassembled components, lacquers, printed patterns and other products.

Meets standards

ASTM D3884, ASTM D1175, ASTM D1044, ASTM D4060, TAPPI T476, ISO9352, IS05470-1, JISK7204, JSA1453, JISK6902, JISL1096, JISK6964, DIN52347, DIN53109, DIN53754, DIN53799, CE compliant, with CE safety marking.

Features

1. Parameters such as moving distance, speed, number of revolutions, load and so on can be set.

2. A variety of different abrasive media and accessories can be selected. (Optional sample holder and other optional accessories for damage testing, alcohol resistance, coin scratch resistance, etc.) )

Note: The size and shape of the general grinding head is like the eraser head at the end of the pencil, and it is made of high-quality abrasive materials. It can ensure the stability of the test.

Standard configuration

Includes 5750 main unit, 3 x 250G disc weights.

1.5 selectable travel distances: 0.5", 1", 2", 3" and 4"; Special travel distances can be customized.

2. The test speed can be set, and the maximum number of revolutions can be set to 999,999 revolutions (note that the grinding head eraser may need to be replaced during this period).

3.2~60 back and forth/min adjustable movement speed. Among them, the six speeds of 2, 15, 30, 40 and 60 round-trips/min are LABER standard measurements, and the higher movement speed of the machine is 60 round-trips/min.

4. Optional load.

Standard load range: measuring rod 3509, 3 weights of 2509 weight are randomly configured;

ASR-5750

ASR-5750