Netherlands TQC GL0010 Gloss Meter 60 ° Single Angle Glossiness Meter

SE-

QILI MN60 Portable Glossmeter Universal, Single Angle Glossiness Meter$ 353.00SE

QILI MN60 Portable Glossmeter Universal, Single Angle Glossiness Meter$ 353.00SE -

Defelsko PosiTector GLS60-3 Single Angle Glossmeter Advanced$ 2745.00SE

Defelsko PosiTector GLS60-3 Single Angle Glossmeter Advanced$ 2745.00SE -

Defelsko PosiTector GLS 60 single angle Glossmeter standard edition$ 2184.00SE

Defelsko PosiTector GLS 60 single angle Glossmeter standard edition$ 2184.00SE -

PUSHEN WGG-60 Portable Gloss Meter Charging Type 60 °$ 290.00SE

PUSHEN WGG-60 Portable Gloss Meter Charging Type 60 °$ 290.00SE -

KSJ MG6-F2 intelligent Gloss meter, projection angle 60 °

KSJ MG6-F2 intelligent Gloss meter, projection angle 60 °

TQC sheen GL0010 Gloss MeterSPEC

TQC sheen GL0010 Gloss MeterDetails

TQC sheen GL0010 Gloss MeterPacking list

- SKU

- NB000315

- Measurement angle

- 60°

- Measurement range

- 0~2000GU

- Repeatability

- 0.2 GU

- Reproducibility

- 1.58GU

- Error of indication

- 0.6GU

- Graduation

- 0.1GU|1GU

- Measuring Areas

- 20*9mm

- Measurement port size

- 10*50mm

- Standards

- ISO 2813、ASTM D523、 ASTM D2457、ASTM C584、 AS 1580 (602.2)、 BS 3900 D5、DIN 67530、 JIS Z 8741、ISO 7668、MFT 30064

- Interface

- USB port

- Data storage

- 2000 readings, maximum 8 batches, 2000 readings per batch

- Display

- OLED display

- Operating language

- English

- Dimensions

- 90*140*45mm

- Weight

- 398g

- Power

- 2 AA alkaline batteries

- software

- TQC analysis software

- Measurement speed

- 70 measurements per minute at 3 angles

- security

- password protection

- Measurement mode

- MIN Minimum, MAX Maximum, Average, Standard Deviation, Number of measurements

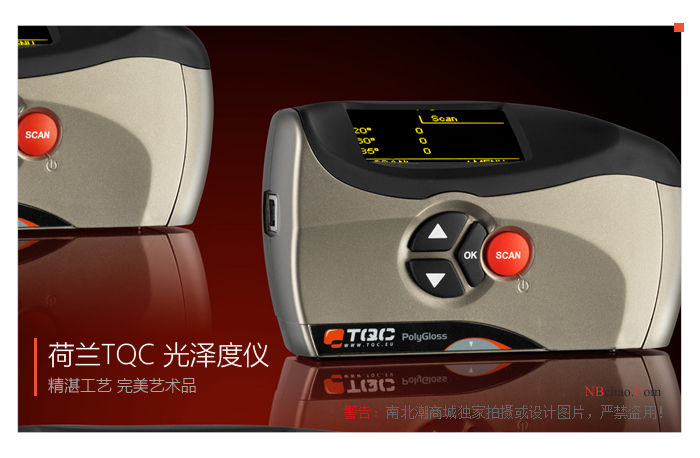

Introduction

TQC 60° single-angle gloss meter is the preferred instrument for measuring the semi-gloss range (suitable for medium-gloss surfaces). Suitable for most applications. When the gloss meter is placed, the light source forms an angle of 60° with the surface being tested. The TQC GL0010 single-angle gloss meter allows users to quickly and easily measure accurate gloss levels on any flat surface, whether it is paper, paint, plastic, wood or any other material, and does not require special training or skills.

The user only needs to place the gloss meter at the position to be measured, press the scan button, and then read the value.

Specifications

| model | GL0010 |

| Measure angle | 60Ë |

| scope | 0-2000GU |

| Repeatability | 0.2GU |

| Reproducibility | 1.58 GU |

| deviation | 0.6GU |

| *According to ISO 2813 (range 0-100 GU) | |

Applications

⢠Automobile industry

⢠paint

⢠Paper industry

⢠Plastic

⢠floor

â¢Packaging Materials

⢠Yacht manufacturing

⢠Furniture products

⢠Large household appliances

⢠Home electronics

⢠Pottery industry

⢠food

⢠Others

Applicable standards

ISO 2813, ASTM D523, ASTM D2457, ASTM C584, AS 1580 (602.2), BS 3900 D5, DIN 67530, JIS Z 8741, ISO 7668, MFT 30064 (45Ë angle exception).

Features

⢠Optical stability;

⢠LED light source;

⢠OLED display, extremely high visibility and contrast;

⢠Ergonomically shaped for both left- and right-handed users;

⢠USB port;

⢠Users can calibrate themselves;

⢠Menu operations.

warranty period

The warranty period is 12 months.

Gloss meter use

No special training or special skills are required. Place the instrument on the object to be measured, press the "scan" button and take a reading. If you want to know the functions of the GL0010 gloss meter software, please read the introductory article " About TQC Gloss Meter Software Interface " in the NBCHAO Knowledge Base .

How to maintain the gloss meter?

â¢Although the material is sturdy, this gloss meter is a precision instrument and cannot be dropped or knocked.

â¢Keep it clean and tidy.

â¢Use a soft, dry cloth to clean the instrument. Do not use other materials such as wire brushes and sandpaper to clean the instrument. Use of detergents may cause lasting damage.

â¢Do not use compressed air to clean the instrument.

â¢When the gloss meter is not in use, keep it in its case.

â¢We recommend annual calibration.

safety precaution

â¢Do not use it in an environment with too high or too low temperature.

â¢Keep the gloss meter dry.

Product actual pictures

Take you into the Dutch TQC

- 1GB/T 23454-2025《Stone plate for vanity and countertop and windowsill》

- 2GB/T 13217.2-2024《Test method for gloss of ink》

- 3GB/T 11420-1989《Measurement of specular gloss of vitreous and porcelain enamels》

- 4GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 5HG/T 2006-2006《Thermosetting powder coatings》

- 6GB/T 33876-2017《Method for measuring gloss uniformity of image on colour copied pages》

- 7GB/T 23997-2009《Solvent-thinned polyurethane wood coatings for indoor decorating and refurbishing》

- 8HG/T 5183-2017《Water-based ultraviolet curing coatings for woodenware》

- 9HG/T 5180-2017《Water-based Coatings for Automotive Plastic Parts》

- 10ASTM D3794-2022《Standard Guide for Testing Coil Coatings》

GL0010

GL0010