IPRE BJ-500X Computer Portable Metallurgical Microscopy

Ipre BJ-500X Computer Portable Metallurgical MicroscopySPEC

Ipre BJ-500X Computer Portable Metallurgical MicroscopyDetails

Ipre BJ-500X Computer Portable Metallurgical MicroscopyPacking list

- SKU

- NB031685

- Optical inspection system

- Optical inspection system for color difference correction

- observation head

- Monocular observation tube

- eyepiece

- Large field of view WF10X (0019 18mm)

- Long distance flat field color difference objective

- PL L 10X/0.25 WD8.8mm;PL L 20X/0.4 WD8.6mm;PL L 40X/0.6 WD3.73mm

- converter

- Inward Ball Inner Positioning Three hole Objective Lens Converter

- lighting system

- 6V3W LED lighting, rechargeable lithium battery

- base

- X-Y Magnetic Base

- Metallographic analysis system

- JX2016 metallographic analysis software, 3 million camera device, 0.5X adapter mirror interface, micrometer

Introduction

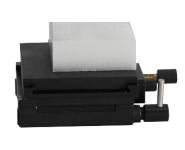

BJ-500X computerized portable metallographic microscope is an upgraded version of BJ-X portable metallographic microscope, the machine can be installed with three objective lenses at the same time, eliminating the trouble of replacing the objective lens, its magnetic base and the fixed structure of the host, increasing the stability of the machine, more convenient and fast to use in the field, and the upgrade of optical components makes its imaging effect better. It is suitable for metallographic inspection of a variety of large workpieces in the field, and the microscope for failure analysis, it does not need to cut and sample, and directly grinds and polishes the workpiece, so as to ensure the integrity of the workpiece. Portable metallographic microscope is suitable for aviation manufacturing, machinery manufacturing, vehicle manufacturing, boiler and pressure vessel manufacturing and inspection, petrochemical, railway, shipbuilding, power plant, power station, equipment installation, large mold, safety testing, quality supervision, physical and chemical laboratory and other industries. It can also be widely used in factories and laboratories for the identification of casting quality, raw material inspection or the research and analysis of metallographic structure after material treatment.

Features

Magnetic base:

The microscope comes with a magnetic base, which can be directly fixed on the sample, with a magnetic suction seat, and a gear-type XY axis moving stage to ensure that the transverse does not draw down by itself.

Nosepiece:

Inward-facing ball-oriented three-hole objective converter for simultaneous mounting of three objectives,Eliminate the hassle of changing objective lenses.

Options

| eyepiece | Large field of view WF10X(Φ18mm) with cross differentiation ruler |

| Long-pitch plan achromatic objectives | PL L 50X/0.7 WD2.02mm |

| Computer | HP Business Jets |

| Grinding kit | Angle Grinder, sandpaper, wool felt, diamond polish, etc |

BJ-500X

BJ-500X