ZKP Ipre SR131 Deep Slot Sensors

SEIpre SR131 Deep Slot SensorsSPEC

Ipre SR131 Deep Slot SensorsDetails

Ipre SR131 Deep Slot SensorsPacking list

- SKU

- NB031710

- name

- Pinhole Sensors

- application

- Roughness of the inner surface of the hole with an aperture greater than 2mm can be measured, the maximum depth is 9mm, and the plane cylinder can also be measured.

sensor type

Using the IPREB RS 100 standard sensor, it can measure the roughness of plane and cylindrical surfaces, and can measure the minimum diameter of the inner hole of 5mm and the maximum depth of 22mm.

Using the IPRERS110 curved surface sensor, it can measure the roughness of the concave-convex workpiece surface with a curvature radius greater than 6mm, and can also measure suitable planes and cylinders. The IPRE RS110 curved surface sensor needs to be used with the IPREO TA620 measuring platform.

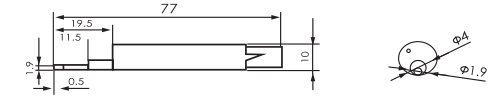

Using the IPREORS 120 small hole sensor, it can measure the surface roughness of the hole with a diameter greater than 2mm, the maximum depth is 9mm, and it can also measure the plane and cylinder. IPRE@ RS120 small hole sensor needs to be used with IPREB TA620 measuring platform.

Using the IPRE@ RS130 groove sensor, it can measure the surface roughness of grooves with a groove width greater than 2mm and groove depth less than 3mm, or steps with a height less than 3mm, and can also measure planes and cylinders. IPRE'RS130 groove sensor needs to be used with IPREBTA620 measuring platform.

Using the IPREE RS131 deep groove sensor, it can measure the surface roughness of grooves with a groove width greater than 3mm and groove depth less than 10mm, or steps with a height less than 10mm, and can also measure planes and cylinders. IPRE@RS131 deep groove sensor needs to be used with IPREBTA620 measuring platform.

Sensor Specifications

RS100 standard sensor |  |

| Using the IPRE RS 100 standard sensor, it can measure the surface roughness of plane and cylinder. When measuring the inner surface of the hole, the minimum diameter of the hole is 5mm, and the maximum depth is 22mm. | |

RS110 Surface Sensor |  |

| Using the IPRE RS110 standard sensor, it can measure the surface roughness of concave-convex workpieces with a radius of curvature greater than 6mm. It can also measure suitable planes and cylinders, and it can be used with a platform. | |

RS130 groove sensor |  |

| Using the IPRE RS 1 30 standard sensor, it can measure the surface roughness of grooves with a groove width greater than 2mm and groove depth less than 3mm, or steps with a height less than 3mm. It can also measure planes and cylinders, and it can be used with platforms. | |

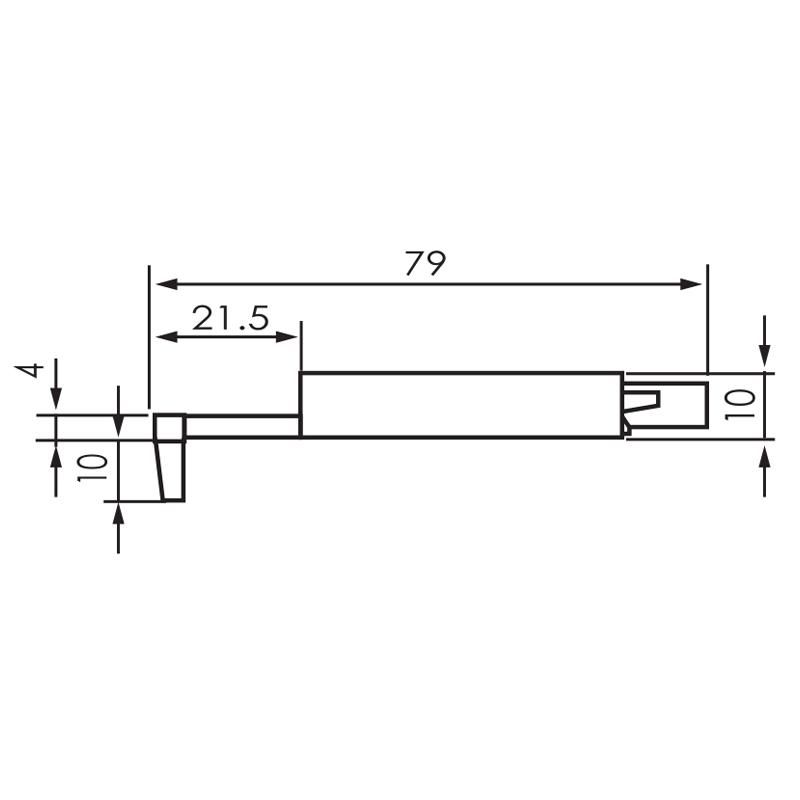

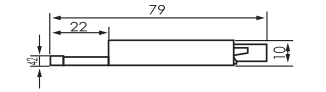

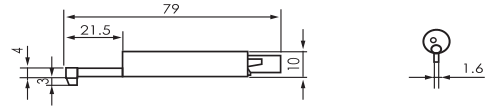

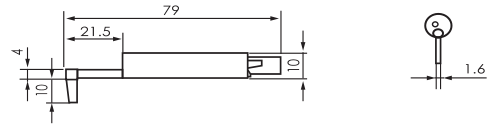

RS131 deep slot sensor |  |

| Using the IPRE RS131 standard sensor, it can measure the surface roughness of grooves with a groove width greater than 3mm and groove depth less than 10mm, or steps with a height less than 10mm. It can also measure planes and cylinders, and it can be used with platforms. | |

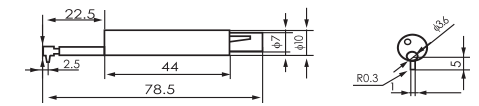

RS120 small hole sensor |  |

| Using the IPRE RS120 small hole sensor, it can measure the inner surface roughness of the hole with a diameter greater than 2mm, the maximum depth is 9mm, and it can also measure the flat cylindrical surface. |

- 1On surface roughness Measuring method Optical inspection, Mechanical, Atomic Force Microscope (AFM)

SR131

SR131