UK RK KHC.11.4 + KHC.21 coating bar Drawdown Plate set 40μm

SERK KHC.11.4 + KHC.21 set Applicator rodSPEC

RK KHC.11.4 + KHC.21 set Applicator rodDetails

RK KHC.11.4 + KHC.21 set Applicator rodPacking list

- SKU

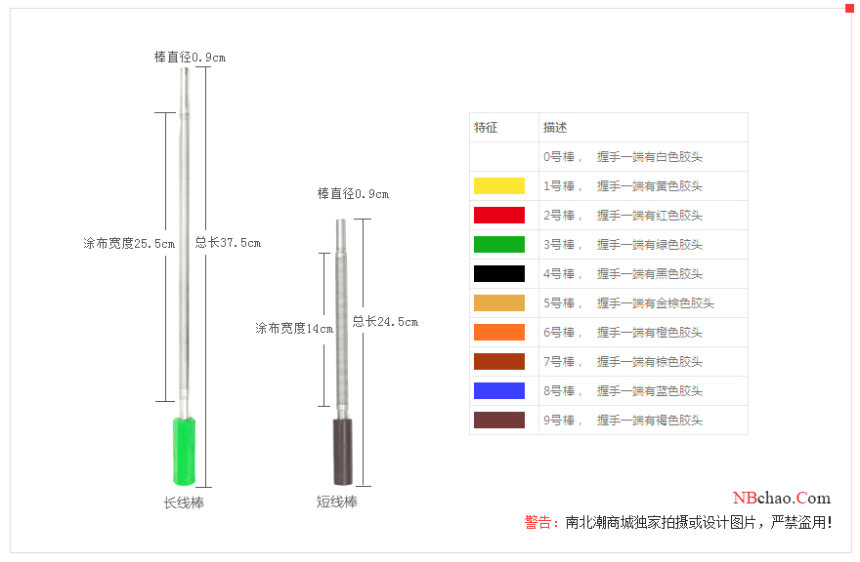

- NB032376

- Production process

- Wire-wound

- WFT

- 40μm

- diameter

- 9mm

- Total length

- 375mm

- Application width

- 255mm

- grip width

- 60mm

- material

- stainless steel

- Drawdown Plate Model

- KHC.21

- Coating table size

- 24*34cm

- Drawdown Plate Net Weight

- 2.08kg

- Baseplate size

- 430*247*12mm

- Packing size

- 476*260*83mm

- Drawdown Plate Gross Weight

- 2.37kg

- Drawdown Plate Material

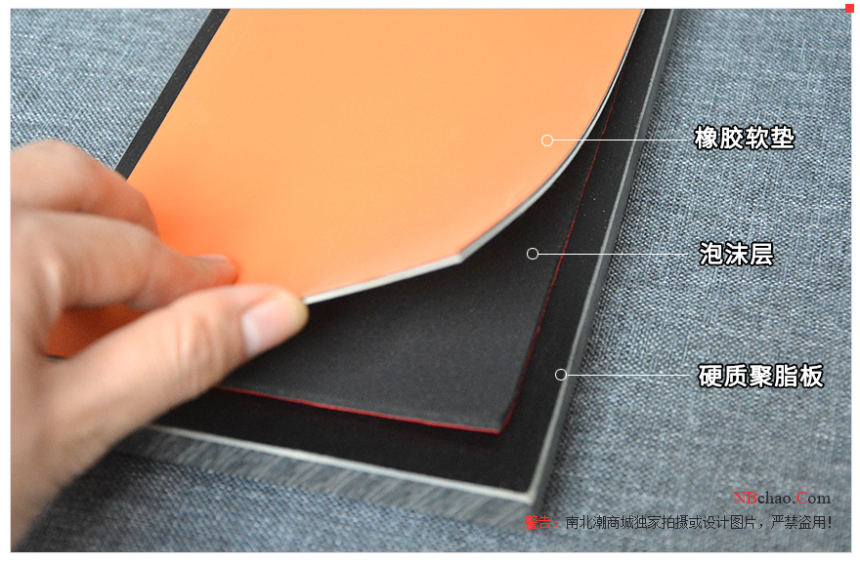

- rigid polyester board + foam layer + rubber cushion

Introduction to RK wire rod

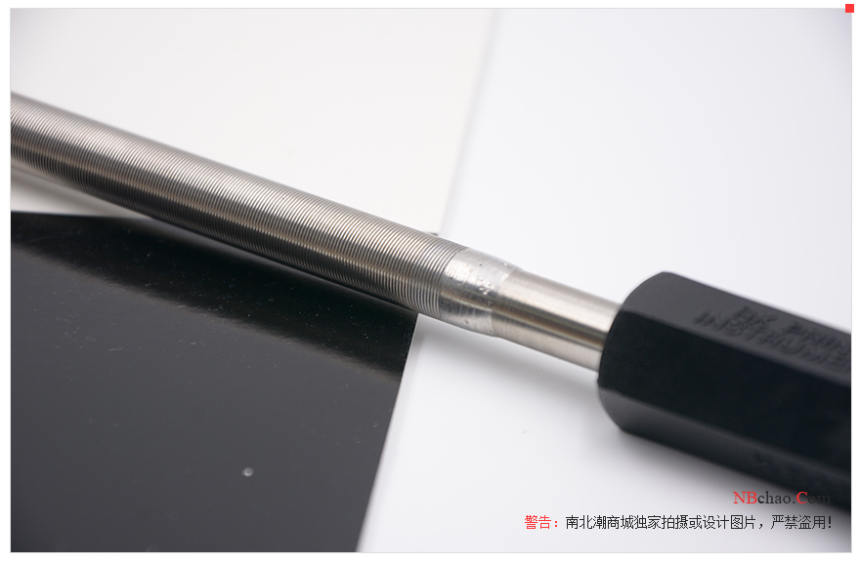

The RK wire Bar Coater is a high-end wire Bar Coater imported from the UK. The workmanship is wire-wound type. The RK wire bar can apply two or more coatings at the same time in one operation and can be used for comparison sample preparation. The RK wire rod applicator has a distinctive appearance design. One section of the handle is designed with plastic. The colors of the plastic parts of different models are different, making it easier for users to identify different rod numbers. Each RK wire rod number is available in two types: long rod and short rod, with lengths of 24.5cm and 37.5cm respectively. There are also wire rods used on coating machines.

The RK4 wire Bar Coater is a hot-selling model, and the KHC.14.4 is a long wire bar. The coating wet film thickness is 40 μm, the Total length is 37.5cm, and the effective coating width is 25.5cm. RK wire Bar Coaters are popular in fields such as ink proofing, packaging and printing, and daily chemicals.

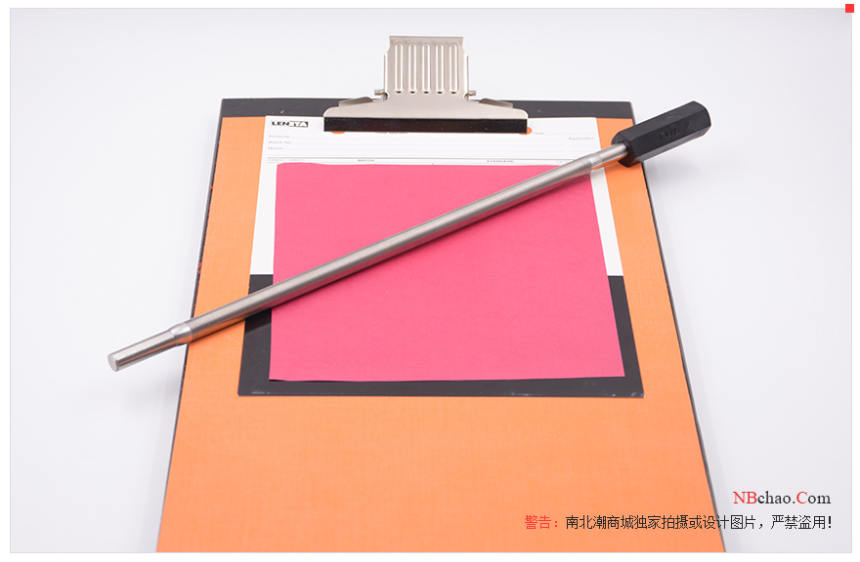

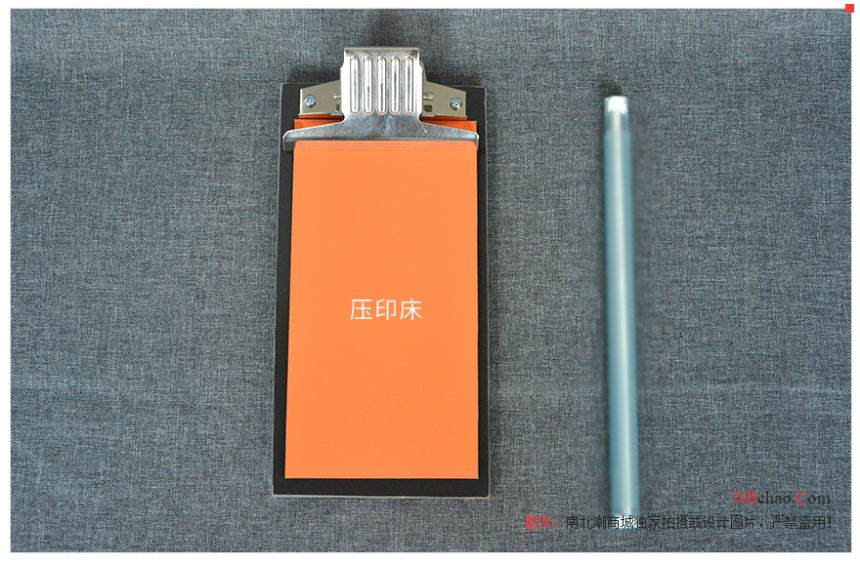

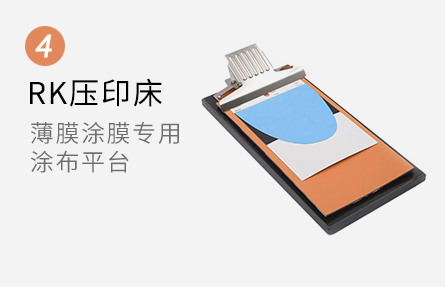

Introduction to KHC.21 Imprinting Bed

The RK imprinting bed is a coating platform designed by RK in the UK. It uses different material combinations to effectively improve the coating and proofing effect. The RK imprinting bed consists of clamps, a rigid polyester board and a foam/rubber cushion. Compared with proofing directly on hard substrates, proofing on the RK printing bed has better repeatability and proofing effects. This is because the soft foam/rubber pad can absorb the pressure exerted by the operator on proofing to a certain extent, resulting in better proofing results.

KHC.21 is a large imprinting bed, used with RK long wire rod applicator, with a size of 430x247x12mm.

Optional

| |

|  |

Note: Click on the accessory image to view product details.

- 1GB/T 22374-2018《Floor coating》

- 2GB/T 1727-2021《General methods for preparation of coating films》

- 3GB/T 7044-2022《Colour carbon black》

- 4GB/T 23997-2009《Solvent-thinned polyurethane wood coatings for indoor decorating and refurbishing》

- 5HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 6HG/T 5370-2018《Waterborne coatings for bicycles》

- 7HG/T 3951-2007《Water based colorants for architectural coatings》

- 8HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

KHC.11.4 + KHC.21 set

KHC.11.4 + KHC.21 set