TQC SP1900 Brinell indentation hardness meter, in line with ISO2815 standard

SETQC sheen SP1900 Indentation Hardness TesterSPEC

TQC sheen SP1900 Indentation Hardness TesterDetails

TQC sheen SP1900 Indentation Hardness TesterPacking list

- SKU

- NB000329

- meet the standard

- EN ISO NF2815-2003、BS3900E9、ECCAT12-1985、NFT30-052

- Standard Accessories

- Special tool with calibrated Weight, LED Illumination Microscope with 20x magnification, a Level, Digital Dual Timer, Marker, 3 AAA batteries

Introduction to SP1900 Brinell Indentation Hardness Tester

The Dutch TQC SP1900 Brinell indentation Hardness Tester is a special standard hardness testing equipment that uses the indentation experimental method for hardness testing. It complies with a variety of international standards, such as ISO2815. The hardness testing of SP1900 Brinell indentation Hardness Tester is recognized by Qualicoat, QIB, GSB laboratories. The needle and cutting part of the SP1900 Brinell indentation Hardness Tester are made of hardened steel, which has good wear resistance and prevents wear of the Hardness Tester.

The complete Brinell Hardness Tester instrument includes a graduated non-slip scratch wheel, illuminated measuring microscope, level gauge, digital dual timer, sample label.

Specifications

| model | SP1900 |

| standard | EN ISO NF2815-2003, BS3900E9, ECCAT12-1985, NFT30-052 |

| brand | TQC |

| Standard accessories | Special knife with calibrated weight, LED illuminated microscope with 20x magnification, a spirit level, digital dual timer, markers, 3 AAA batteries |

Features of SP1900 Brinell indentation Hardness Tester

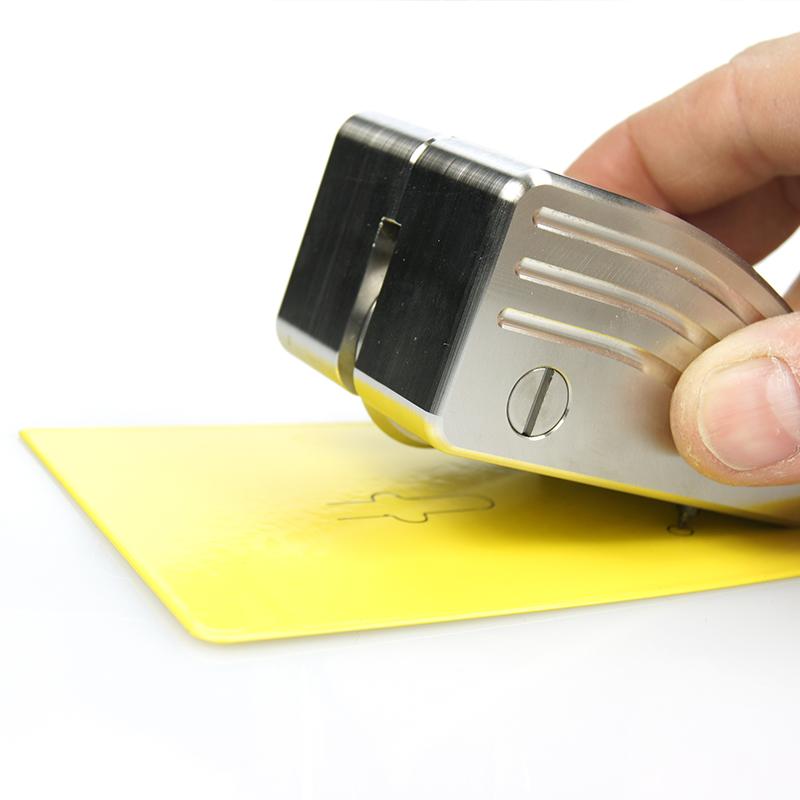

1. The indenter of the SP1900 Brinell Hardness Tester is equipped with an indentation base.

2. The needle and the indenter of the cutting part are made of hardened steel and have very good wear resistance.

3. High-quality microscopes with precision optical glass lenses and powerful lighting allow us to clearly see hard-to-observe indentation marks.

4. Dual timers can be preset to set the "in position" time and "recovery" time ⢠Independent level meter, used to calibrate the horizontal position of the test plate before performing the test

Application of SP1900 Brinell Indentation Hardness Tester

Application: automobiles, coating industry, galvanizing, laboratories, paint and other industries

Actual pictures

Instructions

The test shall be carried out at 23±2℃ and 50±5% Relative Humidity

1. The minimum coating thickness measured by SP1900 Brinell indentation Hardness Tester is 3-45 μm (according to Brinell table)

2. The coating to be tested should be smooth and clean

3. Use a level to ensure the test panel is in a horizontal position

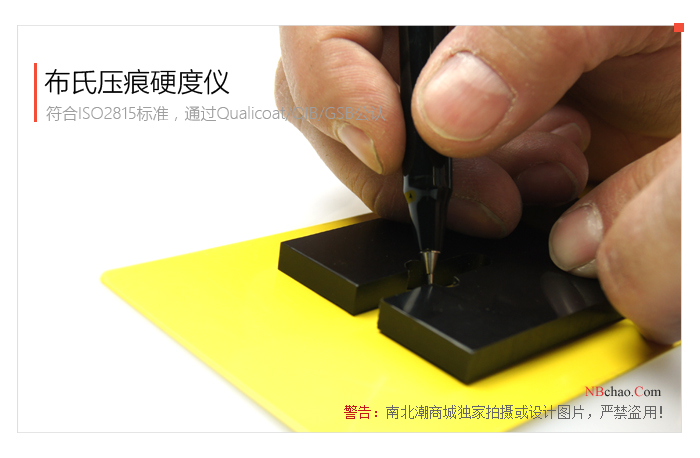

4. Use template marking points for testing and corresponding test locations. The indentation is clearly shown in the middle of the gap.

5. Check the SP1900 Brinell Indentation Hardness Tester indentation body (weight, wheels and fixing points) and make sure they are free of dust

6. Gently and without tilt or lateral movement, place the indentation body on the test plate. Place the needle in the appropriate position first, then slowly lower the indenter until it touches the test plate, and start timer T1.

7. After 30 seconds move the TQC indentation Hardness Tester on the surface of the test plate and press T2. Do not apply any pressure to the indenter during removal.

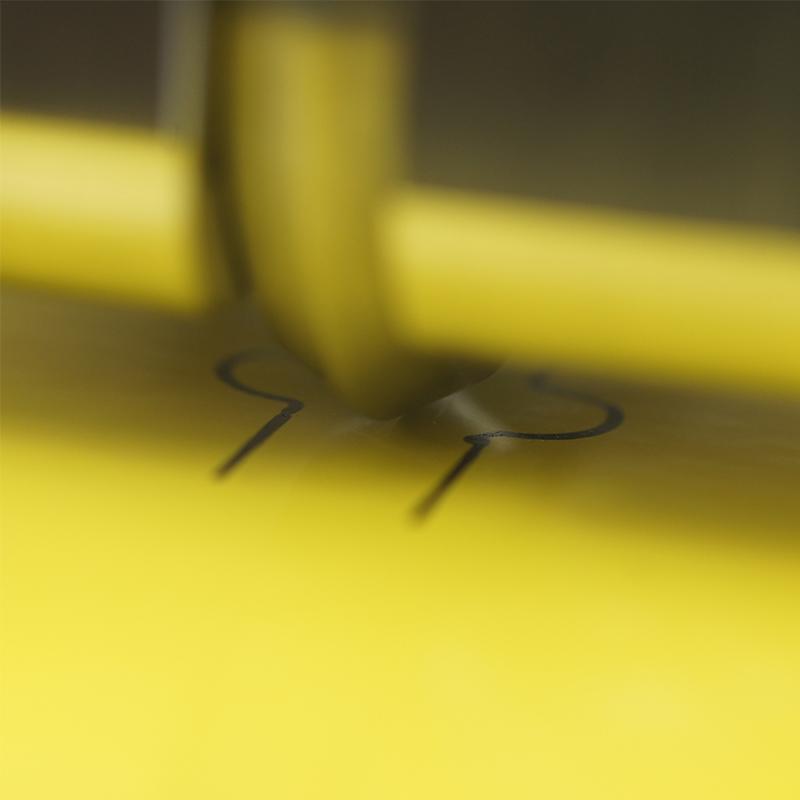

8. After 35 seconds of recovery period, measure the indentation length (L) using a microscope.

9. Find the indentation length L and find the resistance value corresponding to the Bush table or use the formula BH=100/L

Optional for TQC Brinell Hardness Tester

[need to be purchased separately]

SP1935 Template

SP1930 black marker pen

SP1931 white marker pen

LD6170 Surface Microscope 20X

DI0085 digital dual timer

Take you into the Dutch TQC

- 1ASTM -2023《Standard Practice for Instrumented Indentation Testing》

- 2ASTM D3794-2022《Standard Guide for Testing Coil Coatings》

- 3ISO 1520-2006《Paints And Varnishes - Cupping Test》

- 4ASTM D1474-2018《Hardness of organic coatings indentation 》

- 5ISO 2815-2003《Paints and varnishes Buchholz indentation test》

- 6GB/T 9275-2008《Paints and varnishes Buchholz indentation test》

SP1900

SP1900