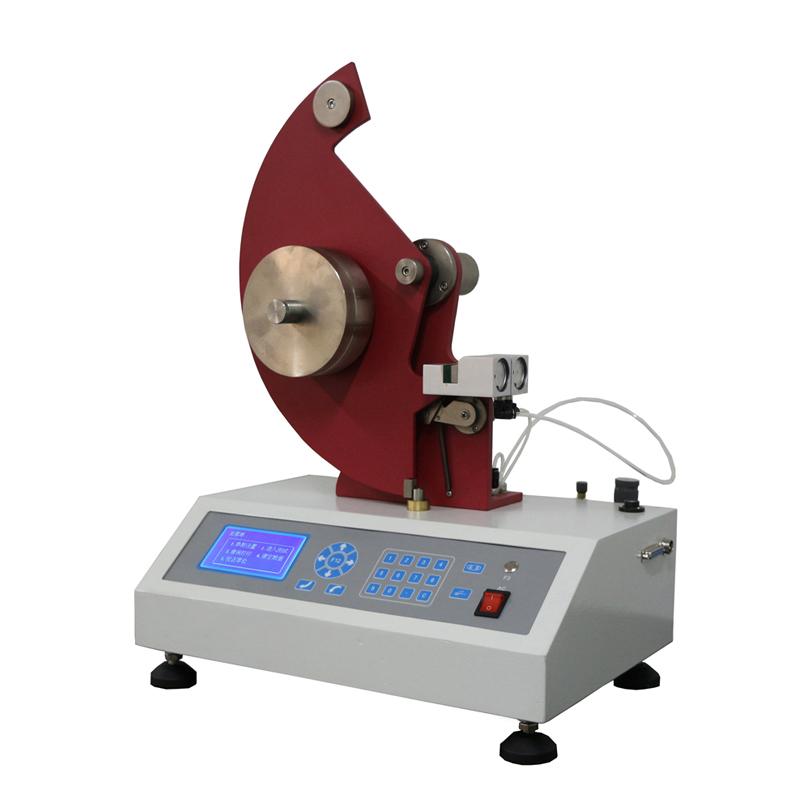

CHENCHI SLY-S1 Electronic Film Tear Tester

LABCHEN SLY-S1 Electronic film tearing MeterSPEC

LABCHEN SLY-S1 Electronic film tearing MeterDetails

LABCHEN SLY-S1 Electronic film tearing MeterPacking list

- SKU

- NB032942

- Measurement range

- 0~16N、32N、64N(16000gf,32000gf,64000gf)可选

- Measurement Accuracy

- 0.2%F·S

- Measurement unit

- N、cN、gf、lbf

- specimen holding

- Pneumatic clamping

- Specimen incision length

- 20±0.1mm

- Distance between clamps

- 2.8±0.3mm

- Dimensions

- 480*420*470mm

- Weight

- 55kg

- Power Supply

- 220V 50Hz 100W

- air source pressure

- 0.6~0.8MPa

Scope of application

SLY-S1 tear Tester is professionally suitable for tear resistance testing of films, sheets, soft polyvinyl chloride, polyvinylidene chloride (PVDC), waterproofing membranes, woven materials, polyolefins, polyester, paper, cardboard, textiles, non-woven fabrics, electrical tapes, metal sheets and other materials. The SLY-S1 Tear Meter is a powerful, multi-industry instrument that has been extensively redesigned with a modern look and a range of new features that deliver superior value, accuracy, safety and flexibility.

Test principle

The pendulum is lifted to a certain height so that it has a certain potential energy, when the pendulum swings freely, the specimen is torn apart by its own stored energy, and the energy consumed when the specimen is torn is calculated by the computer control system, so as to obtain the force required for tearing the specimen.

Scope of application

Basic applications Plastic films, flakes, such as polyolefins, polyesters, aluminum-plastic composite films, etcPaper, cardboard;textile materials

Extended Applications: Heavy Packaging Bags;rubber latex gloves;stretch film;Paper metro tickets

Meets standards

Plastics: GB/T 11999, ASTM D1922, ISO 6383-2, JIS K 7128-2, NF T54 141

Paper: GB/T 455, APPITA P 400, ASTM D 689, BS 4468, CSA D9, DIN 53128, EN 21974,

ISO 1974、JIS P 8116、PAPTAC D9、SCAN P11、TAPPI T414、UNI 6444

纺织品:GB/T 3917.1、ASTM D1424、DIN 53862、EN ISO 13937-1、ISO 4674-2、ISO 9290、M&S P29、NEXT 17、NF G07-149

Nonwovens: ASTM D5734, WSP 100.1

Instrument characteristics

1. Professional calculation method (potential energy method calculation) to ensure test and good repeatability.

2. Micro control system, automatic testing, calculation, analysis results, printing test reports, uploading test data.

3. Humanized control system, Chinese and English operation interface, simple and convenient operation, all buttons are functional soft keys, and the operation panel is concise and clear.

4. You can freely view all data and statistical results in the host.

5. The test unit can be selected between N, cN, gf and lbf and automatically converted to meet the requirements of different standards.

6. Pneumatic specimen clamping ensures that the clamping force is consistent, and can reduce the operating intensity, and the pendulum release effectively avoids the systematic error caused by human factors.

7. Automatically cut the sample to ensure that the shape of the incision is consistent and can reduce the operation intensity.

8. Equipped with multiple sets of pendulum capacity to meet the different testing needs of users

SLY-S1

SLY-S1