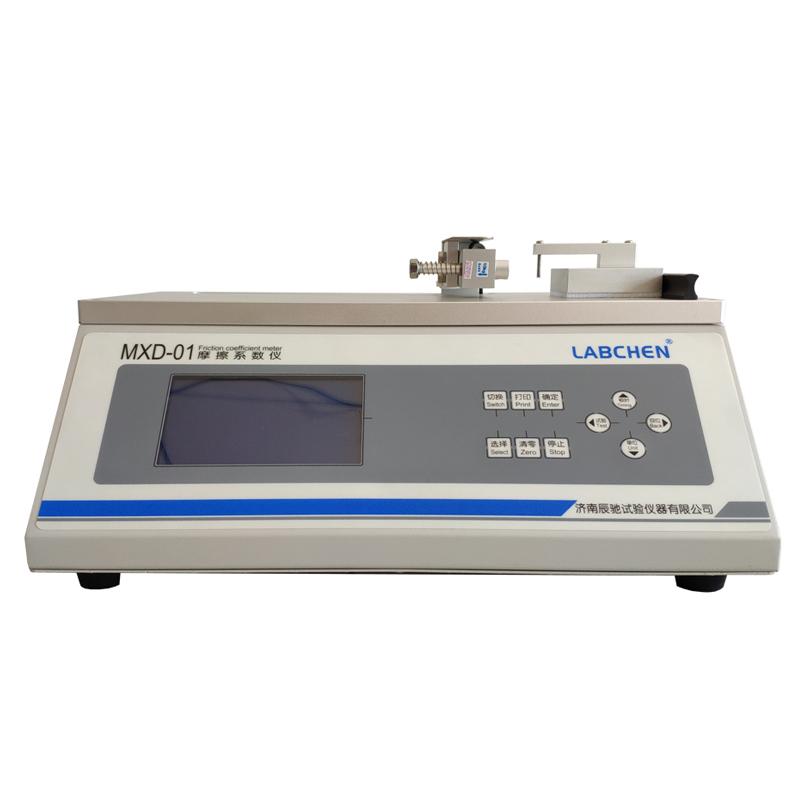

CHENCHI MXD-01 coefficient of friction Tester

LABCHEN MXD-01 Coefficient of frictIon MeterSPEC

LABCHEN MXD-01 Coefficient of frictIon MeterDetails

LABCHEN MXD-01 Coefficient of frictIon MeterPacking list

- SKU

- NB032949

- Force range

- 0~5N

- Measurement Accuracy

- 0.001N

- Slider stroke

- 70mm

- Slider Mass

- 200g

- Slider traverse speed

- 100mm/min

- test conditions

- Standard test environment

- Dimensions

- 400*300*200mm

- Power supply Voltage

- AC 220V±10%50Hz

- Net Weight

- 20Kg

Introduction

MXD-01 coefficient of friction Tester is based on GB 10006 national standard, which is professionally suitable for measuring the static friction coefficient and dynamic friction coefficient when plastic film and sheet, rubber, paper, cardboard, woven bag, fabric style, metal material composite belt for communication cable and optical cable, conveyor belt, wood, coating, brake pad, wiper, shoe material, tire and other materials slide. By measuring the slip properties of the material, the quality and process indicators of the material production can be controlled and adjusted to meet the requirements of product use. In addition, it can also be used to measure the slip properties of cosmetics, eye drops and other daily chemical products.

Features

1. The equipment is controlled by microcomputer, the test process is automated, with menu-type operation interface, PVC control panel and LCD screen, which is convenient for users to carry out test operation and data viewing.

2. The system accessories are all familiar with the manufacturer's components, the performance is stable and reliable, and the high-precision force sensor achieves high test accuracy: 0.001N

3. No mechanical knob, full digital system, digital correction and zeroing.

4. Specially designed drive system, smooth operation, more accurate test results.

5. The system can measure the static friction coefficient and dynamic friction coefficient of the sample at the same time.

6. Equipped with a micro printer to automatically print the test report of a single piece or a group of samples.

7. The instrument test table and test slider have been degaussed and remanent detection, which effectively reduces the system test error.

8. Group data, embedded data statistical analysis function.

9. The interface design of the instrument is simple, the operation is simpler, and the use is convenient.

Basic application

1. Film is suitable for static friction coefficient and dynamic friction coefficient testing of plastic films and thin sheets

2. Paper is suitable for testing the dynamic and static friction coefficient of paper and cardboard

3. Textiles, non-woven fabrics, and woven bags are suitable for testing the static friction coefficient and dynamic friction coefficient of textiles, non-woven fabrics, and woven bags

4. Rubber is suitable for the static friction coefficient and dynamic friction coefficient test of rubber

5. Aluminum foil, aluminum foil composite film, and metal products are suitable for testing the static friction coefficient and dynamic friction coefficient of aluminum foil, aluminum foil composite film, and metal products

6. Printed matter is suitable for static friction coefficient and dynamic friction coefficient test of printed matter

Product Features

1] The equipment is controlled by microcomputer, the test process is automated, with menu-type operation interface, PVC control panel and LCD screen, which is convenient for users to carry out test operation and data viewing;

2] The system accessories are all familiar with the manufacturer's components, the performance is stable and reliable, and the high-precision force sensor achieves high test accuracy: 0.001N;

3] Five-inch LCD screen displays results, parameters, and test curves;

4] Embedded maximum,mostStatistical analysis functions of data such as small values and average values;

5] No mechanical knob, full digital system, digital correction and zeroing;

6] Specially designed drive system, smooth operation, more accurate test results;

7] The system can simultaneously measure the static friction coefficient and dynamic friction coefficient of the sample;

8] Equipped with a micro printer to automatically print the statistical analysis test report of a single piece or a group of samples;

9] The instrument test table is made of aluminum alloy, which effectively reduces the influence of the remanence of the iron table on the system test error;

10] In order to ensure the stability of the system, the instrument adopts three power supply modes, which effectively reduces the power supply interference between each component;

11] The instrument has its own force calibration mode, which supports single-point and multi-point force calibration;

- 1GB/T 44757-2024《Anodizing coating on titanium and titanium alloys》

- 2GB/T 16311-2024《Specification and test method for road traffic markings》

- 3SY/T 6863-2012《Calibration method of mudcake coefficient device》

- 4GB/T 41899-2022《General quality requirements for coated tinplate and ECCS used in food container》

- 5GB/T 27740-2011《Cast polypropylene(CPP) film》

- 6GB/T 4456-2008《Polyethylene blown film for packaging applications》

- 7GB/T 12967.1-2020《Test methods for anodic oxidation coatings and organic polymer coatings of aluminium and aluminium alloys―Part 1: Measurement of abrasion resistance》

- 8HG/T 5299-2018《Optical polyethylene terephthalate(PET) transparent hardening film for indium tin oxide(ITO)》

- 9GB/T 2005-19787《Heat-shrinkable polyolefine films for packaging materials》

MXD-01

MXD-01