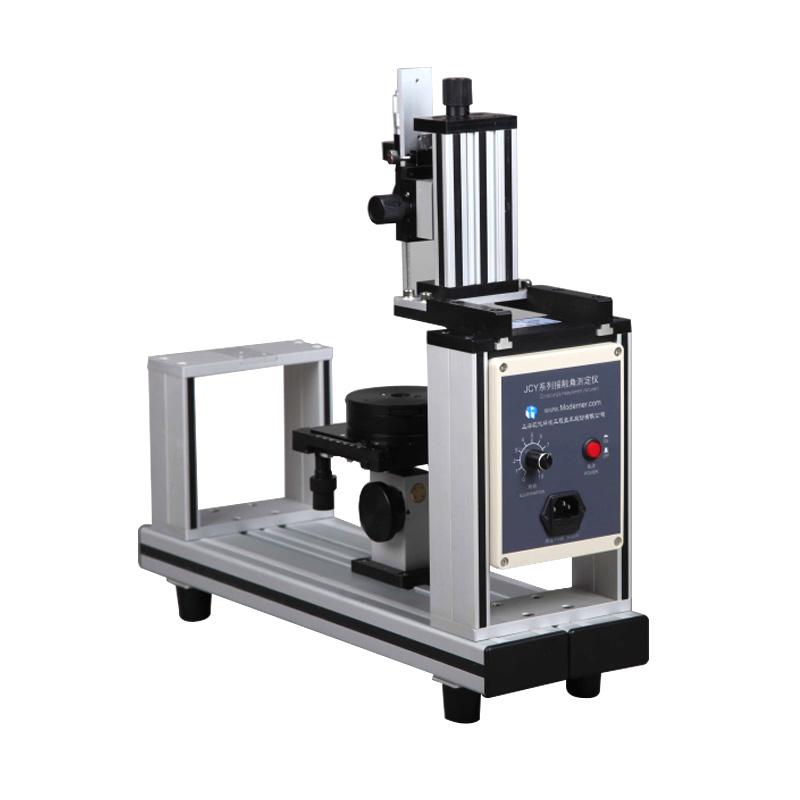

MODERNER XD-26-JCY-3 contact angle Tester

Moderner XD-26-JCY-3 Contact angle TesterSPEC

Moderner XD-26-JCY-3 Contact angle TesterDetails

Moderner XD-26-JCY-3 Contact angle TesterPacking list

- SKU

- NB033082

- Camera system

- Professional CCD Digital Camera + High Performance Microscope

- Maximum resolution

- 1280×1024

- How to take pictures

- Single sheet, continuous

- meet the standard

- ASTM D 724、ASTM D 5946、ISO15969

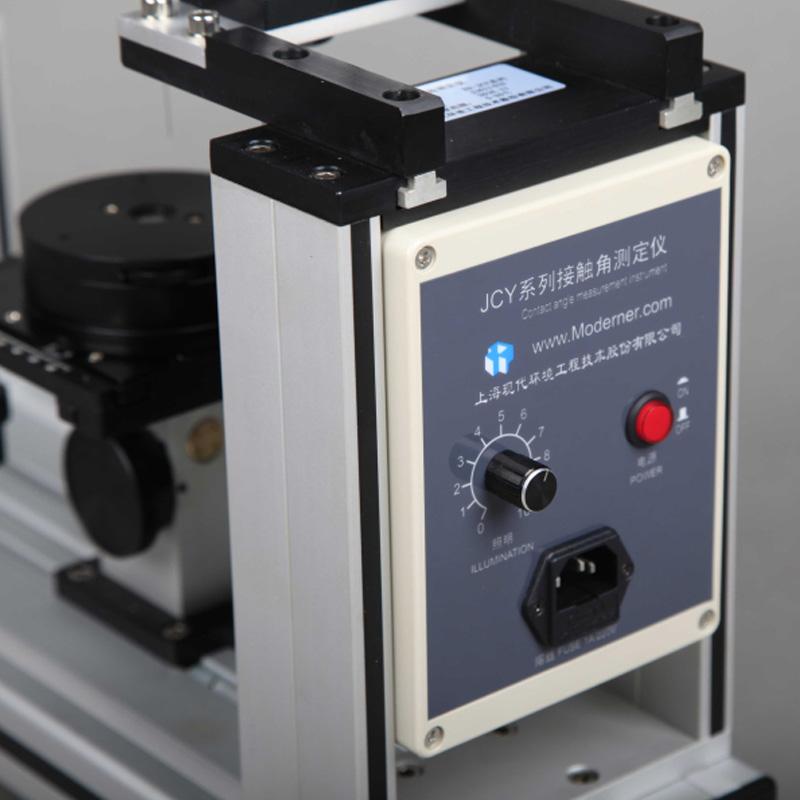

- Light source

- LED Cold Light source with continuously adjustable luminance, uniform emission, clearer image contour and higher resolution

- Contact angle analysis method

- 0/2 method, tangent method, can be calculated automatically or manually (corrected)

- Contact angle Measurement Range

- 0~180°

- Contact angle test resolution

- 0.01°

- Solid surface energy

- Calculation of Surface Energy, Droplet Volume and Solid Adhesion by One Liquid Method and Two Liquid Method

- Surface tension test method

- S-H form, form factor method

- Surface tension Measurement Range

- 0~400mN/m

- Surface tension test resolution

- 0.01mN/m

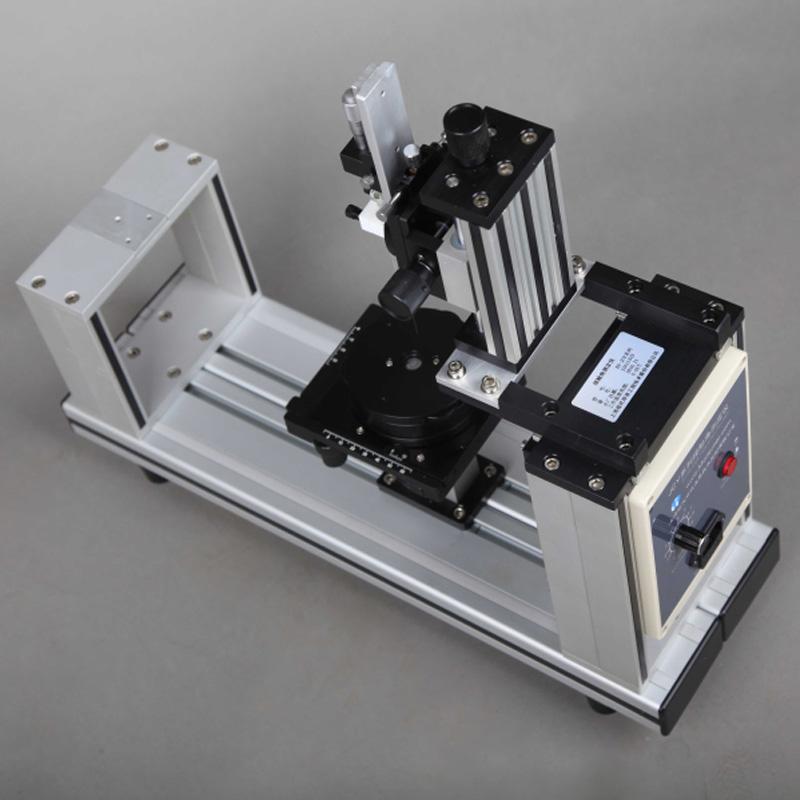

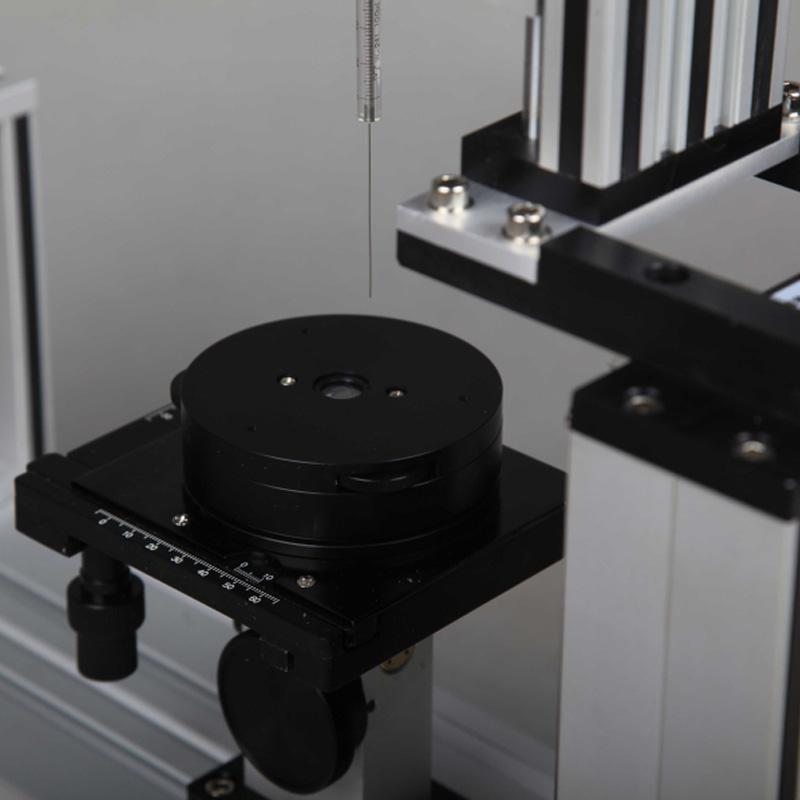

- Sample stage displacement

- Front and rear: 60mm; left and right 35mm; up and down 50mm, the sample stage can be adjusted horizontally, and the diameter is 90mm.

- Sample Stage Size

- 105×120mm

- Maximum sample thickness

- ≤35mm

- Tilt platform

- without

- Injection method

- Manual Sample injector

- Dimensions

- 525*160*470mm

- Net Weight

- 12Kg

- Power

- 220V/50Hz

- Power

- 0.2KW

- Surface tension Measurement Range

- 0~400mN/m

Introduction

XD-26-JCY series contact angle measuring instrument is a standard instrument used to measure solid contact angle, surface energy, etc. and liquid surface tension. Using professional optical video measurement technology, the images captured by high-precision industrial cameras are sent to the computer for data processing. It has complete functions and is very convenient to operate. Comply with ASTM D 724, ASTM D 5946, ISO15969 and other standards. It is widely used in quality testing of industrial and mining enterprise laboratories and scientific research in colleges and universities.

main feature

1. Using the new CCD camera system, the image of the measured droplet can be clearly displayed on the computer screen for high-precision contact angle analysis and measurement. The highest resolution of the camera: 1280Ã1024, frame rate: 15 or 45/ Second

2. High-precision level control, the combination of hardware level correction and software level correction (curve baseline correction) achieves more accurate horizontal line alignment of the contact angle curve

3. It adopts aviation aluminum body, which is both light and stable.

4. Automatic calculation of contact angle, left and right contact angle comparison function

5. Dynamic contact angle analysis system, including contact angle analysis that changes with time, advancing angle/retreating angle, tilt angle, and rolling angle analysis

6. Solid surface energy estimation: Surface free energy estimation using Fowkes one-liquid method, Owen two-liquid method, Zisman method, Acid-Base method, etc.

7. The software comes with a brightness correction function to modify the image brightness.

8. Multiple testing methods: hanging drop method, seat drop method (intravenous drop method)

9. Surface tension measurement: hanging drop method (Youngâs equation) to measure liquid surface tension

10. Database management functions: query, backup, compression, and export of EXCEL tables

11. The operation calculation software is based on WIN XP and VIAST systems

Application scope

During the metal welding process, the adhesion of the flux to the metal is tested;

Adhesion between ink, metal, and paper in the printing industry;

Study on the degree of adhesion between adhesive and solid;

In the aerospace industry, the degree of wetting of aircraft substrates by aerial rain and fog is detected;

Determination of the contact angle between shrapnel and rain and fog in the air in military science;

During the oil extraction process, the determination of the advancing angle and receding angle of the injected additives and the solids in the crude oil;

Determination and research on the wettability between nanomaterials and different active agents;

Determination of hydrophilic angle of aluminum foil.

Comparison of parameters of contact angle measuring instrument series

| model | XD-26-JCY-1 | XD-26-JCY-2 | XD-26-JCY-3 | XD-26-JCY-4 |

| camera system | Professional CCD digital camera + high-performance microscope lens | |||

| highest resolution | 1280Ã1024 | |||

| How to take pictures | Single, continuous | |||

| light source | Continuously adjustable brightness LED cold light source emits uniform light, and the captured images have clearer outlines and higher resolution. | |||

| Contact angle analysis method | 0/2 method, tangent method, automatic calculation or manual (correction) calculation | |||

| Contact angle measurement range | 0~180° | |||

| Contact angle test resolution | 0.01° | |||

| solid surface noto | Calculation of surface self-energy, droplet volume, and solid adhesion force using one-liquid method and two-liquid method | |||

| Surface Tension Test Method | none | SH table development, shape factor method | ||

| Surface tension test range | none | 0~400mN/m | ||

| Surface tension test resolution | none | 0.01mN/m | ||

| Sample stage displacement | Front and rear: 60mm; left and right 35mm; top and bottom 50mm, sample stage can be adjusted horizontally, diameter 90mm | |||

| Sample stage size | 105Ã120mm | |||

| Maximum sample thickness | â¤35mm | |||

| tilt platform | none | Measure advance/retreat angle and sliding angle | none | Measure advance/retreat angle and sliding angle |

| Injection method | Manual microsampler | |||

| Dimensions | 525Ã160Ã470 (lengthÃwidthÃheight, mm) | |||

| net weight | 12kg | |||

| Power and power | 220V, 50Hz 0.2KW | |||

- 1 2099-2024《Calibration Specification for Optical Contact Angle Measuring Instruments》

- 2NY/T 1860.31-2016《Guidelines on the determination of physico-chemical properties of pesticides.Part 31: Surface tension of aqueous solutions》

- 3GB/T 42694-2023《Textiles—Testing and evaluation for surface wetting resistance—Contact angle and rolling angle method》

- 4GB/T 24368-2009《Test method for hydrophobic contamination on glass by contact angle measurement》

- 5GB/T 36086-2018《Nanotechnology—Determination of contact angles of nanopowders—Washburn dynamic pressure method》

- 6GB/T 30447-2013《Measurement method for contact angle of nano-film surface》

- 7GB/T 13448-2019《Test methods for prepainted steel sheet and strip》

- 8GB/T 30693-2014《Measurement of water-contact angle of plastic films》

- 9GB/T 13448-2006《Test methods for Prepainted Steel Sheet》

XD-26-JCY-3

XD-26-JCY-3