HUITAI BPHJS-100B Programmable Humidity chamber

HuiTai BPHJS-100B Humidity chamber programmableSPEC

HuiTai BPHJS-100B Humidity chamber programmableDetails

HuiTai BPHJS-100B Humidity chamber programmablePacking list

- SKU

- NB033549

- Interior Volume

- 100L

- Interior size

- 450*400*550mm

- Temperature range

- -40~150℃

- Temperature Fluctuation

- ±0.5℃

- Temperature Uniformity

- ≤±1.5℃

- Temperature deviation

- ±1.5℃

- Heating rate

- 1.5℃/min;RT+→200℃≈40min

- test method

- GB/T 5170.2-2008 temperature test equipment, the calculation method of the average rate of temperature change according to the 8.4.6 of GB/T 5170.2-2008

- Humidity control range

- 30~98%R.H

- Humidity Deviation

- +/- 3% R. H (Humidity Deviation : +/- 5% R. H at ≤ 75% R. H)

- Enclosure Material

- 1.2Mm Advanced Cold Hot Plate Nano Paint

- Chamber material

- 1.0Mm stainless steel plate SUS304 #/brushed plate

- Viewing Window

- Multilayer Hollow Electric Glass

- noise

- ≤ 72dB (A), one meter away from the front of the box and one meter above the ground for measurement

- Refrigeration system

- France taikang fully enclosed compressor.

- refrigerant

- R404A, ozone depletion index is 0

- refrigeration method

- air-cooled

- Display

- TH1800

- Display

- 7-Inch display, resolution: 16bit, color touch screen

- Display resolution

- Temperature 0.1 ℃; Humidity: 0.1% RH; Time 1min

- Temperature transducer

- Class A Pt100 Armored Platinum Resistor

- Memory

- SD card

- Power

- AC380V 50HZ

1. Equipment characteristics

1. Design basis and guiding ideology

1.1 This product is an extension of our company's HF series of standard products. Similar products have mature applications in electrical and electronics, automobiles, scientific research, military industry, solar energy and other units.

1.2 This technical plan is prepared based on the technical documents provided by the customer, combined with the installation site conditions and other information.

1.3 Product design and manufacturing must be technically professional, with stable equipment performance, reliable use, simple operation, and convenient maintenance, while taking into account the economy and implementability of the solution.

1.4 Ensure the usability, reliability, professionalism and safety of process equipment;

1.5 Use mature and reliable new technologies to reduce energy consumption, save costs and improve quality;

1.6 The selection of accessories adopts the principle of combining domestic (CN) and foreign products. Chinese equipment uses products from well-known domestic (CN) manufacturers, and key equipment and electrical components use imported or joint venture products to ensure the professionalism, stability and normal service life of the equipment. ;

1.7 The electrical control is designed according to process and equipment requirements, complies with relevant national electrical standards, operates reliably, and takes into account electrical protection and interlocking functions.

2. High performance & low energy consumption

Professional air supply design:

The air duct with built-in baffle fan volute is used to ensure uniform air temperature field in the box and small temperature deviation;

Cool down:

Fin-type effective evaporator has strong frost resistance, small heat transfer temperature difference and fast cooling rate;

Low power consumption:

Compressor return air cooling circuit and energy adjustment circuit; optional "cold end output" type to more effectively save energy consumption.

3. High reliability

Refrigeration:

3.1.1 Use French Taikang fully-hermetic compressor, which has complete safety protection functions and high reliability;

3.1.2 The main refrigeration and vacuum accessories are all of the best international brands;

3.1.3 Regulate and protect compressor suction pressure to ensure compressor safety under various Operating Conditions.

control:

TH1800 "controller, 7-inch" color touch screen, equipped with electrical actuators mainly from French Schneider and Japanese Fuji. The system is fully automatic controlled and has high operation reliability.

4. Simple operation

Simple operation: the touch screen controller displays Chinese menu bar and is easy to operate;

Host computer: optional remote monitoring computer, the control system realizes redundant control and remote monitoring;

Using a high-precision temperature sensor, the measurement accuracy is high and the drift is small.

The compressor suction and exhaust pressure is displayed in real time for easy inspection and maintenance; (optional function).

The internal silencer of the unit and the bottom vibration reduction design reduce the transmission of vibration and noise.

The Test Chamber can design the test interface according to user requirements.

5. Complete functions

Complete test functions: high/low temperature constant temperature test, high-low temperature cycle test.

It has complete functions such as remote control of the host computer and dry air purging (optional), making it easy for users to choose according to the situation.

6. Easy maintenance

Self-diagnosis: The control system has a self-diagnosis function. When overtemperature, compressor overpressure, overload, fan overload and other faults occur, the controller will display the cause of the fault in Chinese and give detailed solutions;

Maintenance: Install a water filter in front of the condenser to facilitate regular cleaning and prevent the condenser from being clogged, causing a reduction in cooling rate or even over-pressure protection shutdown;

History records: Both the touch screen and the optional PC display interface can view temperature history records and alarm records.

2. Relevant standards

sequence | project | content |

1 | Meet test method | GB/T 2423.1-2008 Test A: Low temperature test method, IEC68-2-1 |

GB/T 2423.2-2008 Test B: High temperature test method, IEC68-2-2 | ||

GB/T2423.3â2008 Constant damp heat test, IEC68-2-78 | ||

GB/T2423.4â2008 alternating damp heat test, IEC68-2-30 | ||

GB/T2423.22-2008 test Nb temperature change test | ||

GJB150.3Aâ2009 High Temperature Test | ||

GJB150.4A-2009 Low temperature test | ||

GJB150.9A-2009 Damp heat test | ||

GJB573A-1998 301 Temperature and Humidity Test | ||

2 | Product manufacturing standards | GB/T10589-2008 Technical conditions for low Temperature Test Chamber |

GB/T11158-2008 High Temperature Test Chamber technical conditions | ||

GB T5170.1-2008 General principles for inspection methods of environmental testing equipment in the electrical and electronics industry | ||

GB/T5170.2 Basic parameter verification method |

3. Box structure

The Test Chamber is composed of four major parts: the insulation box, the refrigeration unit, the air supply device, the control and safety protection system. It adopts an integral design and can be used after it is installed on site and connected to the power supply.

1.1 Cabinet

The box body adopts an overall upper and lower structure, with the working room at the upper part and the unit system at the lower part.

The side walls of the thermal insulation box equipment are in order from the inside to the outside: stainless steel inner wallâexternal reinforcementâinsulation material layerâdecorative shell

1.2 Shell

Advanced hot and cold plate nano paint

1.3 Insulation layer

PU (polyurethane) foam + ultra-fine centrifugal glass wool composite insulation layer with high temperature resistance and suitable thermal insulation effect, thickness 100mm.

1.4 Inner wall

The inner wall of the box is made of 1.0mm SUS304/2B stainless steel plate, and all seams are TIG welded continuously to ensure that there will be no leakage after long-term testing.

The outer wall of the inner box is welded and the main positions are reinforced.

Drainage holes are designed on the inner wall bottom plate to drain the condensed water in the box out of the box.

1.5 box bottom

The channel steel at the bottom of the box is welded and formed, with a load-bearing capacity of â¥100kg/m².

Cabinet layout

Directly in front of the upper part of the Test Chamber is the door of the box, and behind the box is the air-conditioning air supply system.

Air conditioning supply

Side air supply: The air conditioning box is at the rear of the studio, with a circulating fan, heater, copper tube aluminum fin evaporator, humidifier, etc. installed inside.

A 0.1HP stainless steel long-axis motor is installed on the top of the box, and a stainless steel centrifugal fan impeller is installed on the top of the air-conditioning box. The air is evenly supplied through the air outlet baffle fixed inside the volute to meet the temperature uniformity requirements.

door

Single hinge anti-collision door (left hinge, right handle), door opening size 1000WÃ1000H mm, rotating hinge can ensure that the door opening angle is not less than 120°;

The door hinges adopt reinforced hinges to ensure free opening and closing.

An anti-frost electric heating belt is installed on the inner edge of the door, and the control system automatically turns on the heating and defrosting according to the temperature of the studio.

Observation window

A set of multi-layer laminated glass observation windows with a viewing area of ââ300Ã400 is installed on the door. When the studio temperature is lower than the ambient temperature, the controller automatically turns on the defogging function of the observation window.

The observation window is composed of pressure-resistant tempered glass + multi-layer hollow electric heating frost-proof glass.

The electric anti-frost glass is the most advanced conductive coated glass in CHINA. This observation window has the advantages of high light transmittance, good heat insulation effect, and no resistance wire on the glass surface to affect the observation. When the studio temperature is lower than the ambient temperature, the system automatically Turn on the defogging function of the observation window to ensure clear observation under any Operating Conditions.

illumination

There is a set of 9W lighting fixtures built into the observation window to ensure that the specimens in the box can be clearly observed under any Operating Conditions.

test hole

One Φ50mm test hole is installed on the left side of the box, located in the center (customer can specify)

Control cabinet

The control cabinet hanging box is installed at the rear of the box, with a distribution board and exhaust fan installed inside. The water and electricity control center isolation design ensures the safety of the Test Chamber.

4. Installation and use conditions

1. Atmospheric environment

Ambient temperature: 5℃ï½+35℃, Relative Humidity: â¤85% RH;

Air pressure: 86kPaï½106kPa

2. Venue

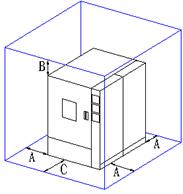

Leave appropriate space for use and maintenance around the equipment, as shown in the figure below:

A: Not less than 1000mm

B: Not less than 1000mm

C: Not less than 1300mm

The ground is flat and well ventilated. There is no strong vibration around the equipment. There is no strong electromagnetic field around the equipment. There are no flammable, explosive, corrosive substances or dust around the equipment.

3.Power supply

AC380V±10%, 50Hz±1Hz,;

The user needs to configure an independent air or power switch of corresponding capacity for the equipment in the equipment room at the installation site, and lead the power cord to the air switch of the box. The power cord lead hole is at the air switch in the power distribution cabinet of the box.

The grounding resistance is less than 4Ω, and the grounding bolt is on the right rear of the box base.

4.Drainage

The drainage hole of the box is on the left rear of the box base, and a 3-meter DN10 silicone tube is included with the box.

- 1GB/T 5170.2-2017《Inspection methods for environmental testing equipments—Part 2: Temperature testing equipments》

- 2GB/T 2423.34-2005《Environmental testing - Part 2: Test methods - Test Z/AD: Composite temperature/humidity cyclic test》

- 3GB/T 2423.25-2008《Environmental testing - Part 2: Tests methods - Test Z/AM: Combined cold/low air pressure tests》

- 4GB/T 2423.1-2008《Environmental testing - Part 2: Test methods - Tests A: Cold》

- 5GB/T 11175-2002《Testing methods for synthetic resin emulsions》

BPHJS-100B

BPHJS-100B