RDS 45 #L1700φ 30.2 production wire-wound drawdown Bar 102.9μm/1.7m

SERDS RDS 45# L1700Φ30.2 Wire-wound Applicator rodSPEC

RDS RDS 45# L1700Φ30.2 Wire-wound Applicator rodDetails

RDS RDS 45# L1700Φ30.2 Wire-wound Applicator rodPacking list

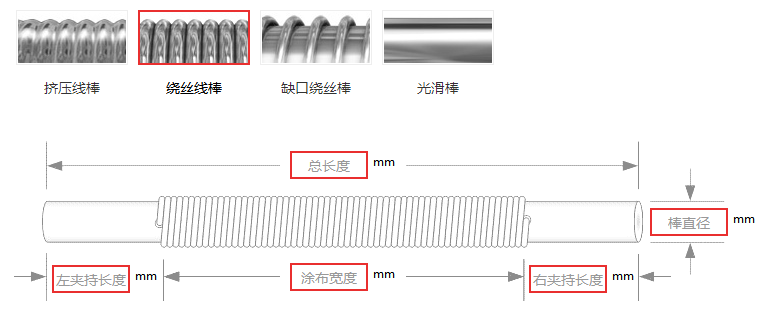

- SKU

- NB033585

- Production process

- Wire-wound

- WFT

- 102.9µm

- Wire diameter

- F1.14mm

- Main rod diameter

- F30.2mm

- Total length

- 1700mm

- Effective Application Width

- 1500mm

- Grip Length

- 100mm

- Mandrel material

- Stainless steel 303

- Surface process

- chrome plating

RDS is a company in the United States that has been developing and producing coating metering rods for more than 80 years (founded in 1936). RDS coating rods have won the favor of a large number of users in CHINA.

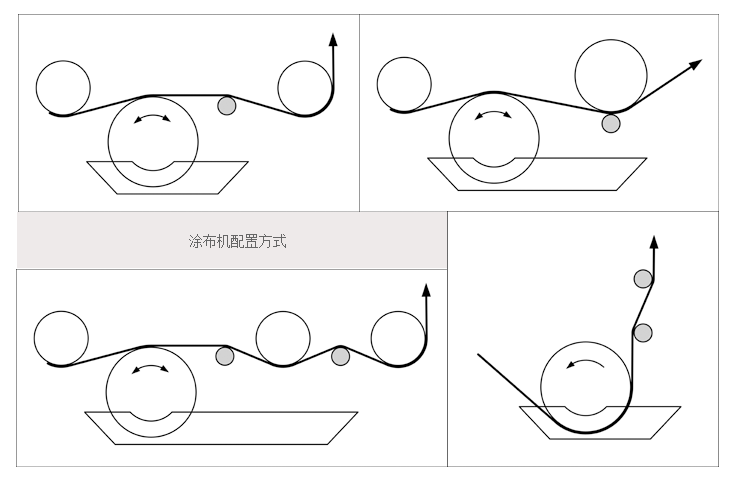

The Mayer rod coating method is simple, accurate, uniform and inexpensive, making it the third most popular method of coating films. Quick changes in coating weight and a wide range of film thicknesses make it flexible enough for a wide range of substrates. We have experience with coater retrofits using metered rod coating stations and can provide a simple solution for most applications.

RDS provides a variety of coating metering rods with different technical specifications to meet the needs of various industries such as coatings, window film manufacturing, tapes, release paper, photovoltaic films, wall covering materials, and specialty papers. Available in wirewound, formed (slotted), doublewound and gapped rod stock up to 12 feet. 15 different diameters of multi-grade stainless steel rods, over 70 sizes of stainless steel wire. Accept customization.

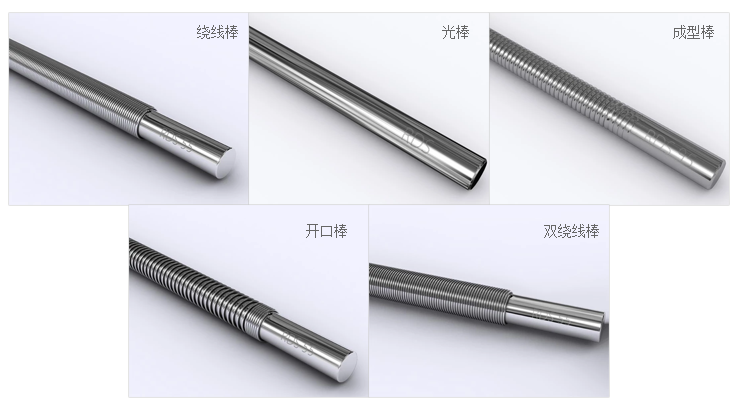

Metering Rod Type

wire wound rod

Original "Mayer" stick. Popularized by Charles Mayer in the 1920s, and still popular. Available in sizes 3 to 75, including many half sizes. Size refers to Wire diameter in mils (.001 inches). wide-wound drawdown Rods can be stripped and rewound for cost savings and less waste. There are no minimum fees for wire-wound rods, and no installation fees.

Forming rod

Formed (threaded, grooved, etc.) rods are rolled from a solid steel rod and are very similar to wire wound rods. The groove is the same size as the cavity between the wire windings and determines the thickness of the coating. However, the radius in the groove of the shaped rod is less prone to clogging and easier to clean than its wire wound equivalent.

smooth stick

Typically used to smooth previously metered paint onto paper, cardboard and plastic film. Coating thickness is controlled by pressure (relative to backup roll) or web force. RDS smooth rods can be ground to meet any surface finish requirement, and hard chrome plating can significantly extend rod life.

notch stick

For higher viscosity materials, gapped rods reduce clogging and eliminate lines. By wrapping the smaller wires at some spacing (see picture), the cavities created are wide and shallow, allowing thick coatings to flow better. Smaller wires create smaller breaks in the coating flow, allowing for more complete wetting of the coating. While gapped rods are less durable than double wound rods, they are also less expensive.

double winding rod

For higher viscosity paints, the double wound rod reduces clogging and eliminates lines. By wrapping a smaller wire around a larger wire (see photo), the cavity created is wide and shallow, allowing thick coatings to flow better. A smaller top line creates smaller breaks in the coating flow, allowing for more complete wetting of the coating. Although double-wound rods are more expensive than gapped rods, they are also more durable.

Coating method

Specification selection

Users can submit customized requirements through the North and South Tide Measurement Rod Customization Tool , and we will quote according to specific requirements. click here

RDS 45# L1700Φ30.2

RDS 45# L1700Φ30.2