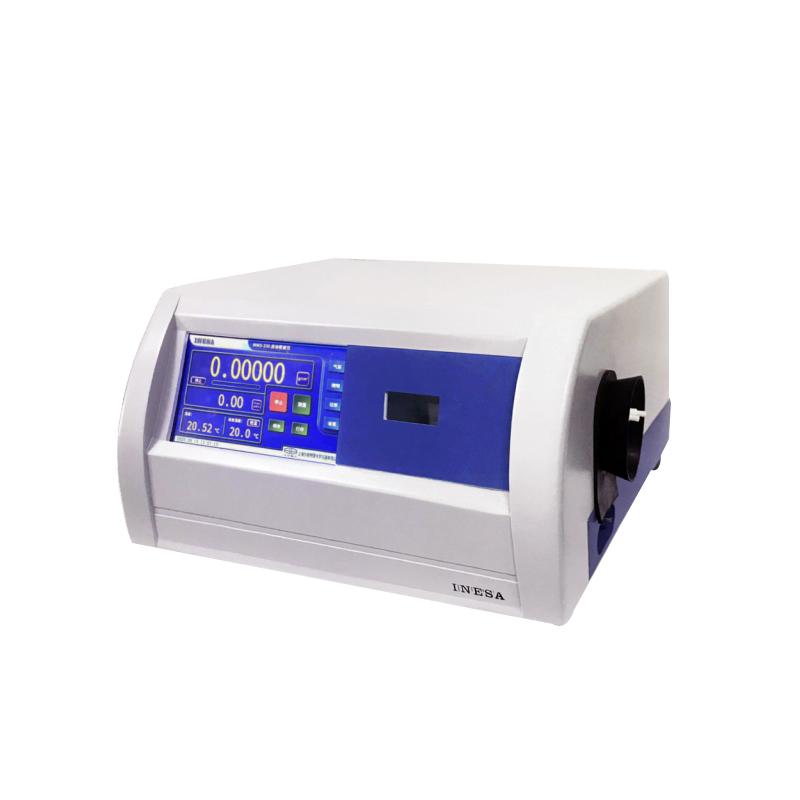

INESA WMD-330 Automatic Density Meter 0.00000~3.00000g/cm3

INESA WMD-330 Automatic Density MeterSPEC

INESA WMD-330 Automatic Density MeterDetails

INESA WMD-330 Automatic Density MeterPacking list

- SKU

- NB033679

- Density range

- 0.00000~3.00000g/cm³

- Measurement mode

- Density g/cm3, density kg/cm3, water specific gravity at the same temperature, 20 degree water specific gravity, sugar whiteness, alcohol concentration (Volume), alcohol concentration (Mass), crude oil specific gravity API index, ethylene glycol concentration, sulfuric acid concentration, nitric acid concentration, muriatic acid concentration, ammonia concentration, etc

- Measurement resolution

- 0.00001g/cm³

- Measuring Accuracy

- ±0.0003g/cm³

- Measurement Repeatability

- ±0.0001g/cm³

- Temperature Resolution

- 0.01℃

- Temperature range

- 15~40℃

- Temperature control Accuracy

- ±0.05℃

- Temperature Control Precision

- ±0.2℃

- injection observation

- Glass window

- calibration method

- Drying air/distillation water

- data storage

- 1000 sets

- Display mode

- 7-Inch color LCD touch screen

- input interface

- touch screen

- output interface

- RS232, USB, USB flash drive

- Printer model

- RD TH-32SC (optional)

- output report

- PDF/Excel

- Power Supply

- 110V~240V,50~60Hz

- Dimension

- 350*440*210mm

- Net Weight of instrument

- 21kg

productsIntroduction

It adopts the working principle of U-tube vibration, which can quickly measure the density of liquid, and has the functions of electronic excitation, vibration frequency counting and display. By injecting a small amount of sample into a vibrating specimen tube, the density of the sample is calculated based on the change in the vibrating frequency of the vibrating tube and the calibration data.

Features

Operation interface: color LCD touch screen display, more intuitive and convenient operation.

Small injection volume: only 2~3ml of the sample to be tested is needed each time, which saves resources and reduces costs.

Measurement modes: built-in density, relative density, specific gravity, Brix, alcohol concentration, oil API index, ethylene glycol concentration, sulfuric acid concentration, nitric acid concentration, hydrochloric acid concentration, ammonia concentration and other measurement modes.

Temperature control: Peltier temperature control device (Peltier) for precise temperature control.

Instrument calibration: Error calibration is simple, and the instrument can be calibrated with only air and distilled water.

Communication interface: equipped with a variety of communication interfaces, data can be saved, exported and printed.

Industry applications

1. Beverage industry: measurement of sugar concentration, alcohol concentration, beer quality control, soft drink quality control

2. Food industry: quality control of grape juice, tomato juice, fructose syrup, vegetable oil and soft drink processing

3. Liquor industry: detection of alcohol concentration of liquor, rice wine, red wine, beer, fruit wine, rice wine, etc

4. Petrochemical industry: crude oil API index, gasoline and diesel density detection, additive mixing process monitoring

5. Chemical industry: chemical urea, detergent, ethylene glycol, acid and alkali and ammonia concentration testing

6. Industry: quality control of APIs and intermediates, determine the specific gravity and density of agents

7. Flavors and fragrances: raw materials for food flavors, daily flavors, tobacco flavors, and food additives

8. Machinery manufacturing: metal processing, machine manufacturing, automobile industry, cleaning agent testing of electronic appliances

9. Inspection institutions: standard laboratories, statutory testing institutions, and third-party testing of liquid density measurement

WMD-330

WMD-330