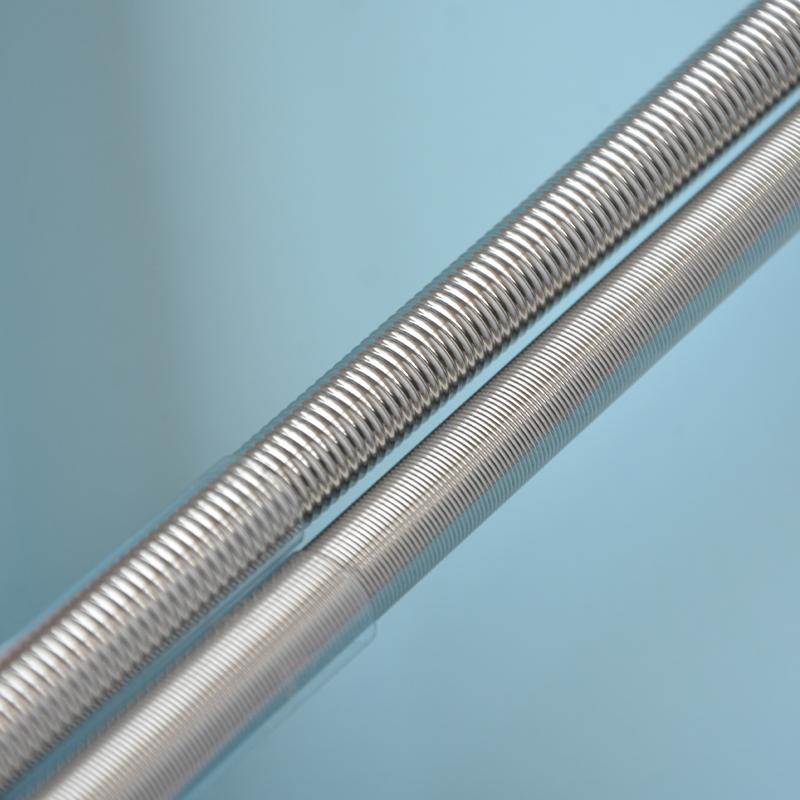

RDS 52 #3/8 "Mayer Rods 118.9μm formed Coating Applicator

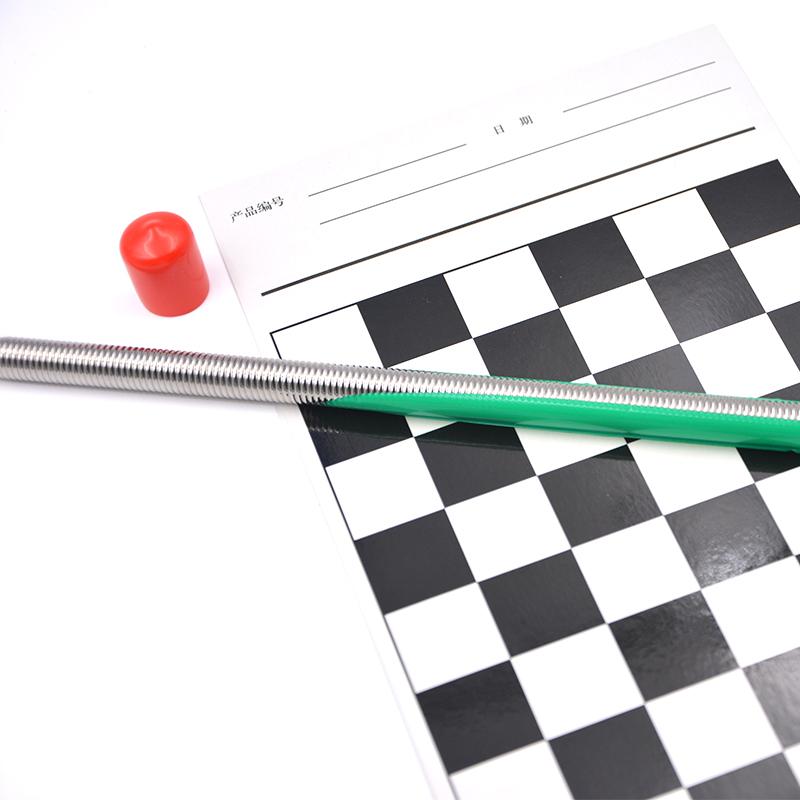

SEThe production process is formed, the wet film thickness is 118.9μm, the diameter is 9.5mm, the Total length is 400mm, the Spreader width is 300mm, and the material is stainless steel.

$162.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

RDS 52 #3/8 "coating scraper, about 120μm wet-film can be prepared$ 162.00SE

RDS 52 #3/8 "coating scraper, about 120μm wet-film can be prepared$ 162.00SE -

UK RK KHC.11.9 Scraper stick wet film thickness 120μm brown glue head No. 9 stick$ 168.00SE

UK RK KHC.11.9 Scraper stick wet film thickness 120μm brown glue head No. 9 stick$ 168.00SE -

Japan OSP-120/60 Applicator rod WFT 120μm length 60mm$ 116.00SE

Japan OSP-120/60 Applicator rod WFT 120μm length 60mm$ 116.00SE -

Pushen XB-I 120μm wire rod, length 240mm$ 98.00SE

Pushen XB-I 120μm wire rod, length 240mm$ 98.00SE -

Japan OSP-120/400 inks bar WFT 120μm length 400mm$ 173.00SE

Japan OSP-120/400 inks bar WFT 120μm length 400mm$ 173.00SE

RDS 52# 3/8" Applicator rod 3/8 "SPEC

RDS 52# 3/8" Applicator rod 3/8 "Details

RDS 52# 3/8" Applicator rod 3/8 "Packing list

- SKU

- NB033736

- Production process

- Formed

- WFT

- 118.9pm

- diameter

- 9.5mm

- Total length

- 400mm

- Application width

- 300mm

- material

- stainless steel

52# 3/8"

Applicator rod 3/8 "

The production process is formed, the wet film thickness is 118.9μm, the diameter is 9.5mm, the Total length is 400mm, the Spreader width is 300mm, and the material is stainless steel.

product description

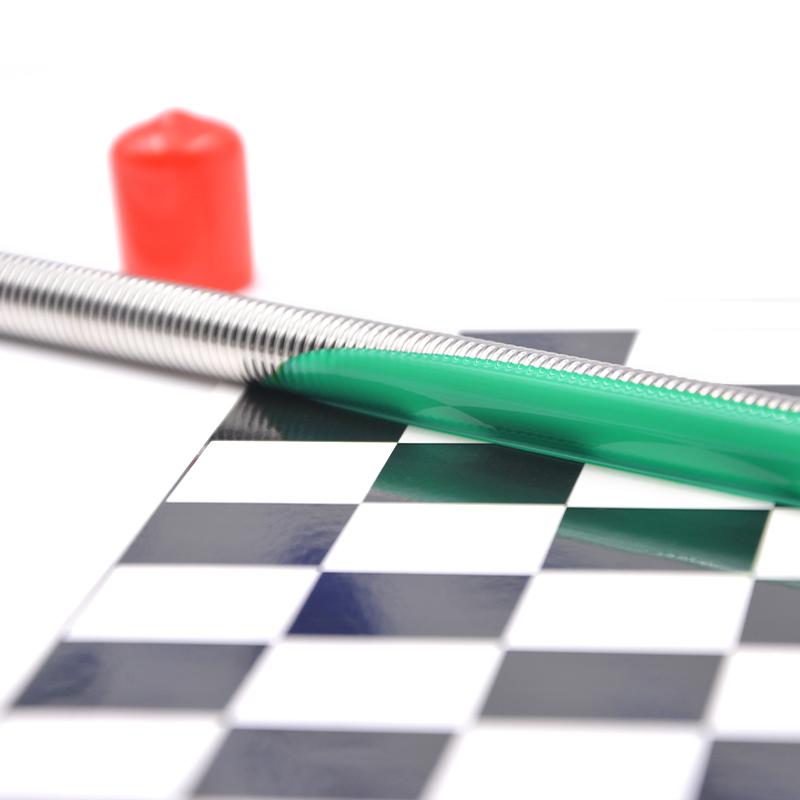

RDS 52# 3/8" wire bar applicator has a film thickness of 118.9 μm and a rod diameter of 9.5 mm. It adopts an extrusion process. The film effect is the same as that of the wire-wound type, and the film accuracy is also up to 0.1μm, which is higher than ordinary extrusion coaters. RDS52 rods also have 6.35mm diameter forming rods, and the coating film thickness is the same.

FAQ

QWhat number of wire rods do you use to scrape aluminum and silver powder?

A

It depends on your Moulding purpose, is it hiding power or Colorimetric? or Miscellaneous performance testing.

QWhat is the difference between the same 3/8 "diameter round Mayer-Rod and this molding rod? Can it be replaced?

A

The main difference between the Mayer-Rod and the molding rod is the different process of groove formation. The wire rods of the same specification and different processes can be replaced by each other, and the wet film thickness is the same. The difference is because the groove shapes of the two are different (the molding is U-shaped groove, and the winding wire is V-shaped groove). The calculation of the Spreader amount is different, and the relative molded Spreader amount will be more. There is no difference for laboratory use.

QMoulding rod is better for winding or extrusion?

A

In theory, the Moulding effect is the same. The extrusion U-groove is relatively easy to clean, but it requires high asperity on the inner wall of the groove. The winding follows the Mayer principle, and the scraping is smoother. If used for pre-production Measurement, the extrusion Spreader is larger than the winding. The same film thickness was prepared in the laboratory, and the effect was the same.

QCan this cable stick be matched with a Film Applicator?

A

Whether it can be matched with the Film Applicator depends on the film width of the Film Applicator. Most Film Applicator film widths on the market are less than 40cm, and the rod diameter is less than 10mm, so it is suitable. But if the Film Applicator is specially customized, or the width exceeds 40cm, you need to choose a longer rod. For customization, please consult NBchao.

QDo you support customization? Such as wet film thickness and length?

A

Spreader rod length and main rod diameter support customization, but wet film thickness RDS has provided dozens of specifications covering more than 200 microns, and in principle does not accept customization.

Knowledge

Standard

- 1GB/T 34676-2017《Interior wall coatings for children's room decorating》

- 2GB/T 1727-2021《General methods for preparation of coating films》

- 3GB/T 7044-2022《Colour carbon black》

- 4HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 5HG/T 5370-2018《Waterborne coatings for bicycles》

- 6HG/T 5065-2016《Finishing varnishes for architectural coatings》

- 7HG/T 3951-2007《Water based colorants for architectural coatings》

- 8HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 9GB/T 9755-2014《Synthetic resin emulsion coatings for exterior wall》

52# 3/8"

52# 3/8"