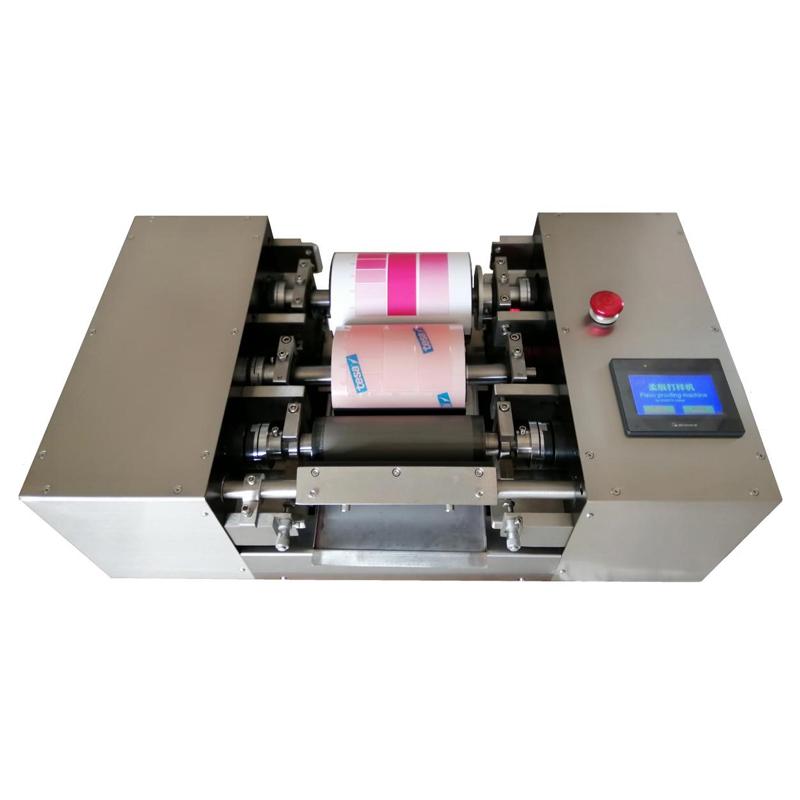

Essence JH-YB Flexographic Proofer

Essence JH-YB flexographic Proofer is suitable for monochrome proofing, using large drum structure, simple and convenient to install printing plate and clean printing plate, JH-YB flexographic Proofer proofing material thickness 0.01-2 mm (bendable material), proofing material size 170x200mm, printing area 117x138mm, plate area 150X 170mm, is a printing adapter.

Model:

Similar products

JingHuaYiQi JH-YB Flexographic ProoferSPEC

JingHuaYiQi JH-YB Flexographic ProoferDetails

JingHuaYiQi JH-YB Flexographic ProoferPacking list

- SKU

- NB033741

- Applicable object

- Monochromatic proofing (e.g. color scheme, testing, etc.)

- Input power

- 220V,50/60Hz

- Power

- 500W

- Inking method

- Dropper ink

- Proofing material thickness

- 0.01-2 mm (bendable material)

- Proofing material size

- 170x200mm

- Printing area

- 117*138mm

- Plate area

- 150X 170mm

- Plate thickness

- DuPont: 1.14mm thick flexographic version, adhesive 0.38mm

- Plate roller and mesh roller pressure

- Soil 2mm adjustment, scale display pressure size

- Plate Roller and Embossing Pressure

- Soil 2mm adjustment, scale display pressure size

- uniform ink rate

- 10-80 meters/minute

- Ceramic mesh roller specification

- (US) φ 70x200mm

- Ceramic mesh roller line number

- Standard 600LPI one (can be customized 70-1200 lines)

- Apply inks

- Flexographic waterborne, UV ink, lithography, letterpress plate plain or UV ink

- Applicable proofing materials

- Paper, Plastic film, Non-woven fabric, Napkin, Gold and silver cardboard, etc

- Dimensions

- 450*810*240mm

- Net Weight of instrument

- 110KG

JH-YB

Flexographic Proofer

Features

1. After the ceramic roller rotates first and the ink is uniform, the printing material and the printing plate cylinder start and rotate synchronously to complete the proofing work for one week, and the ceramic roller, the printing material cylinder and the printing plate cylinder are synchronized in operation to ensure the proofing quality.

2. The four structures of squeegee, ceramic roller, printing plate cylinder and printing material cylinder can be adjusted separately on the left and right, and the adjustment is flexible;

3. The mesh roller and scraper are easy to disassemble and assemble

4. Adopt large cylinder structure, install printing materials, install printing plates and clean printing plates is simple and convenient.

FAQ

QWhat is the printing area of Essence JH-YB Adjacent Proofer?

A

Hello, the printing area is 117x138mm.

Standard

JH-YB

JH-YB