Defelsko PosiTest F Mechanical Coating Thickness Gauge Explosion proof, underwater measurement with certificate

SE-

Defelsko PosiTest G Coating Thickness Gauge for Eletroplating, thin paint layer, steel phosphating film thickness measurement with certificate$ 450.00SE

Defelsko PosiTest G Coating Thickness Gauge for Eletroplating, thin paint layer, steel phosphating film thickness measurement with certificate$ 450.00SE -

Defelsko PosiTest DFT Combo Coating Thickness Gauge for measurement of coarse or cylindrical surface coatings$ 817.00SE

Defelsko PosiTest DFT Combo Coating Thickness Gauge for measurement of coarse or cylindrical surface coatings$ 817.00SE -

Defelsko PosiTest DFT Ferrous steel Coating Thickness Gauge nonmagnetic coatings$ 604.00SE

Defelsko PosiTest DFT Ferrous steel Coating Thickness Gauge nonmagnetic coatings$ 604.00SE -

German EPK MikroTest F6 McCourt coated platings Thickness Gauge, thickness measurement: 0~1000μm$ 840.00SE

German EPK MikroTest F6 McCourt coated platings Thickness Gauge, thickness measurement: 0~1000μm$ 840.00SE -

DONGRU DR220 (upgraded version) Integrated Coating Thickness Gauge 0-2000μm$ 228.00SE

DONGRU DR220 (upgraded version) Integrated Coating Thickness Gauge 0-2000μm$ 228.00SE

Defelsko PosiTest F Coating Thickness GaugeSPEC

Defelsko PosiTest F Coating Thickness GaugeDetails

Defelsko PosiTest F Coating Thickness GaugePacking list

- SKU

- NB003379

- Measurement principle

- Magnetic Induction

- Measurement range

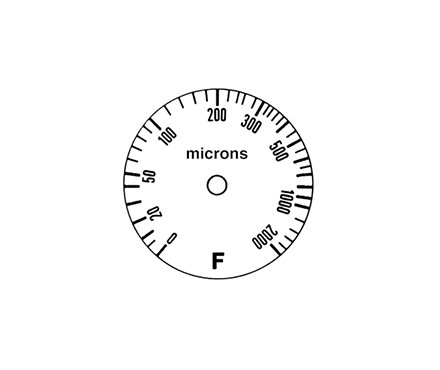

- 0~2000μm

- margin of error

- ±5%

- application

- Hot dip galvanizing, hard chrome, paints, enamel on steel

Introduction to the PosiTest F Mechanical Coating Thickness Gauge

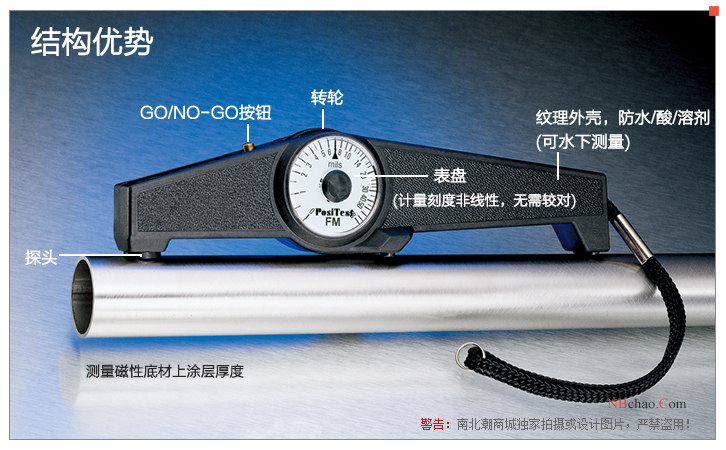

The Defelsko PosiTest F Mechanical Coating Thickness Gauge features a GO/NO-GO button on the top, a thickness scale dial on the front with pulleys on the dial, and a wear-resistant probe with persistent magnetism on the bottom, with a textured housing, making it a mechanical magnetic coating Thickness Gauge. The PosiTest F Mechanical Coating Thickness Gauge has the advantages of simple operation, fast operation, stable and accurate measurement, and the measurement range is 0~2000μm, which is suitable for small parts measurement.

Illustration of the PosiTest F Mechanical Coating Thickness Gauge

Benefits of the PosiTest F Mechanical Coating Thickness Gauge:

1) The thickness measurement is reliable, and the calibration certificate can be traced back to the PTB 2) Textured shell, waterproof, oil, acid, solvent

2) Textured shell, waterproof, oil, acid, solvent

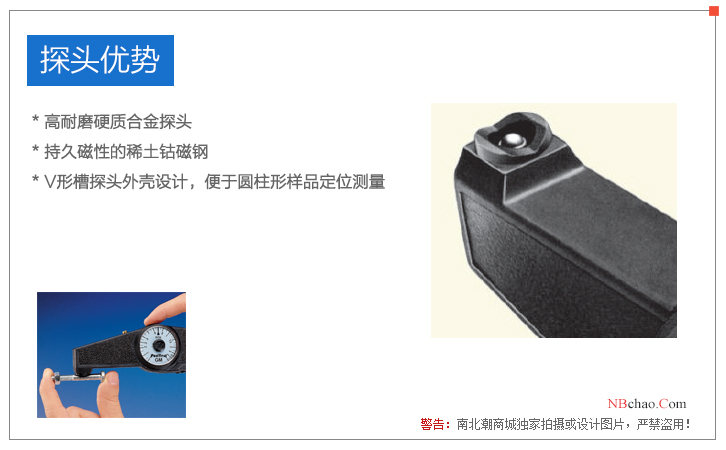

3) The probe is made of high wear-resistant cemented carbide and uses rare earth cobalt magnet with long-lasting magnetism

4) Mechanical, no battery required

5) Measure through the dial and sound prompt

6) Explosion-proof and high safety

7) The included wristband and instruction manual are kept in a high-quality leather case for later use

8) V-groove probe housing, stable and reliable cylindrical measurement

PosiTest F Mechanical Coating Thickness Gauge Operation

1) Place the coating gauge vertically on the object to be measured, so that the probe can touch the surface of the object to be measured.

2) Press the GO/NO-GO button on the PosiTest GM Mechanical Coating Thickness Gauge (i.e., the gold button on the gauge)

3) Gently shake the wheel until you hear a "click", and the thickness indicated by the dial pointer at this moment is the thickness of the coating to be measured.

Comparison of Defelsko PosiTest F&G parameters

| Used for: hot-dip galvanizing, hard chrome, paint, enamel on steel | Used for: electroplating, thin paint film, measurement of phosphating film on steel |

|

|

Measuring range FM: 0~80mil Accuracy FM: ±0.2 mils (within 4mils) ±5% of reading (over 4mils) | Measuring range GM: 0~8mils Accuracy GM: 0.04mils (within 0.8mils) ±5% of reading (over 0.8mils) |

|

|

Measuring range F: 0~2000μm Accuracy F: ±5μm (within 100μm) ±5% of reading (above 100μm) | Measuring range G: 0~200μm Accuracy G: ± 1μm (within 20μm) ±5% of reading (above 20μm) |

- 1Principle and Application Analysis of Coating Thickness Gauge

- 2Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 3Nondestructive measurement Coating thickness

- 1HG/T 3240-2007《Micro-computer film-thickness tester》

- 2QJ 990.3A-2011《Inspection methods of coating.Part 3:Measurement of coating thickness》

- 3NF EN ISO 2808-2007《Paints and varnishes - Determination of film thickness.》

- 4GB/T 42541-2023《Coated steel pipes for gas piping》

- 5GB/T 7991.5-2014《Test method of viterous and porcelain enamels—Part 5:Determination of thickness by electromagnetic mothod》

- 6JJG 818-2018《Magnetic and Eddy Current M easuring I nstrument for Coating Thickness》

- 7GB/T 1727-2021《General methods for preparation of coating films》

- 8HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 9ASTM B499-2021《Standard Test Method for Measurement of Coating Thicknesses by the Magnetic Method: Nonmagnetic Coatings on Magnetic Basis Metals》

- 10ISO 2178-2016《Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method》

PosiTest F

PosiTest F