LANYU LYE500W-T High shear dispersion Mulser 90G/60L 316 material

SELanYu LYE500W-T (set 2) High shear dispersion Mulser 316 materialSPEC

LanYu LYE500W-T (set 2) High shear dispersion Mulser 316 materialDetails

LanYu LYE500W-T (set 2) High shear dispersion Mulser 316 materialPacking list

- SKU

- NB033831

- Rated Voltage

- AC220V

- Rated frequency

- 50/60HZ

- Input power

- 1400W

- output power

- 800W

- Duty Cycle

- S1 (continuous)

- Operation control method

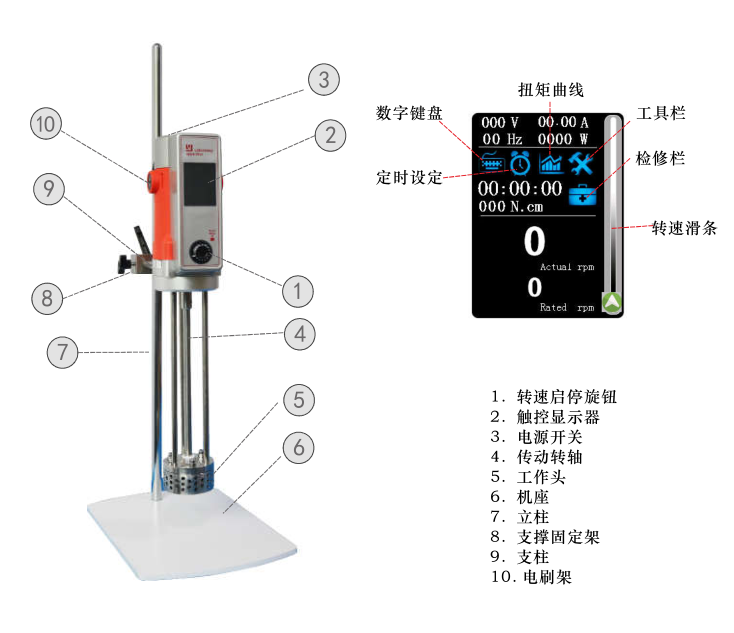

- Touch knob

- Speed range

- 1000~13000rpm

- Speed regulation

- stepless speed regulation

- Timer

- 1~1000min

- Speed display

- TFT-LCD

- Overload protection

- Yes.

- rated torque

- 70N.cm

- Standard throughput

- 500~60000mL

- Maximum Max. Viscosity

- 8000mpa.s

- Allowable environment temperature

- ≤40℃

- Allowable Relative Humidity

- ≤80%

- Dimensions

- 215*310*700mm

- Total Weight

- 10kg

- rated torque

- 35N.cm

- Rotor maximum linear speed

- 22m/s

- Work head material

- SS316L

- Work head specification

- F90mm

- Minimum immersion liquid height

- 50mm

- Maximum immersion liquid height

- 236mm

- Stator standard configuration

- 5mm² 20mm² 50mm²

LYE500W series laboratory shear emulsifier is driven by a compact series-excited miniature high-speed motor, suitable for stirring and mixing low to medium and high viscosity liquids in laboratories or pilot plants, and shearing emulsification of pulverized granular materials in liquid media . The machine is composed of high-speed motor, shear emulsification working head and speed controller. The driving host is made of high-quality engineering plastic and die-casting aluminum alloy, and the running state is stable; the working head is made of high-quality stainless steel, which has a wide range of experimental applications; the operating speed is controlled by a microprocessor, which can instantly and effectively compensate for load changes and power supply fluctuations The constant speed is reliable due to the change of the rotating speed; the built-in soft start and automatic overload protection ensure the safety of continuous operation at full load for a long time in the experiment; the stepless adjustment of the rotating speed meets the need to modify the stirring speed at any time during the experiment. The real-time numerical display of Voltage, frequency, current, output power, output torque, etc. provides convenience for experimental data collection; the operation Timer Control function ensures that the timeliness of the experiment is effective and controllable.

Principle of emulsification

The experimental equipment is driven by a high-speed motor and the shear emulsification working head is precisely matched with the rotating stator, which rotates at a high speed on the rotor. When the working head rotates down, comprehensive kinetic energy such as high frequency, strong circumferential tangential velocity, and angular velocity is formed, so that the experimental materials are sucked into the rotor area from the bottom of the experimental container, and thrown out from the stator hole under the action of huge centrifugal force. And the large stator and rotor form strong and reciprocating hydraulic shearing, friction, centrifugal extrusion, liquid flow collision and other comprehensive effects in the reasonably narrow gap . It reciprocates in the container and withstands tens of thousands of times of shearing, tearing, impacting and mixing per minute, so as to achieve the effect of shear emulsification, and the efficiency of the working process is about a thousand times higher than that of ordinary stirring. That

The laboratory shear emulsifier is suitable for tissue dispersion in the field of biotechnology, sample preparation in the medical field, enzyme treatment in the food industry, and liquid-liquid, liquid-solid phases in the pharmaceutical industry, cosmetics industry, paint industry and petrochemical industry. experimental aspect. Under the triple action of extrusion in the feed liquid, strong impact and pressure loss expansion, the experimental medium can be refined and mixed more evenly to prevent or reduce delamination with the feed liquid. Such as: homogenization and emulsification process in the production process of dairy products, beverages, cosmetics, pharmaceuticals and other products.

Stator configurations of working heads with different specifications are designed to meet different experimental requirements. Covering a wider range of applications - crushing, emulsification, homogenization, polymerization, suspension, dissolution and stirring, etc.

Precautions

The machine should be placed in a clean and dry place, kept tidy and protected from moisture, and the operating environment temperature should not exceed 40°C, and all kinds of foreign matter should be strictly prevented from splashing into the motor.

When the machine is used in a relatively humid environment, please equip it with a leakage protection device to ensure the personal safety of the operator.

This machine is used in the power grid with severe Voltage fluctuations, which will cause the speed to be out of control. Please use a power supply Voltage stabilizer.

When the machine is used in a highly corrosive environment, in order to prevent damage to the mechanical and electrical properties of the equipment, please take necessary protective measures.

If the machine encounters volatile and flammable medium experiments, it is necessary to take strict measures to prevent the emission of flammable gases, so as to avoid deflagration of flammable and explosive gases when they encounter electric sparks, causing fire accidents.

LYE500W-T (set 2)

LYE500W-T (set 2)