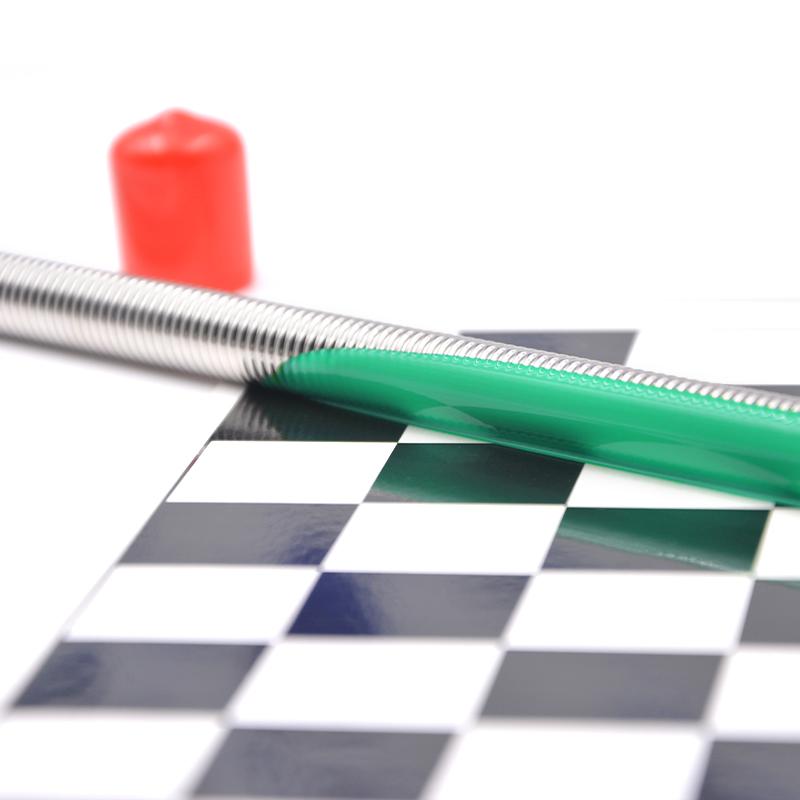

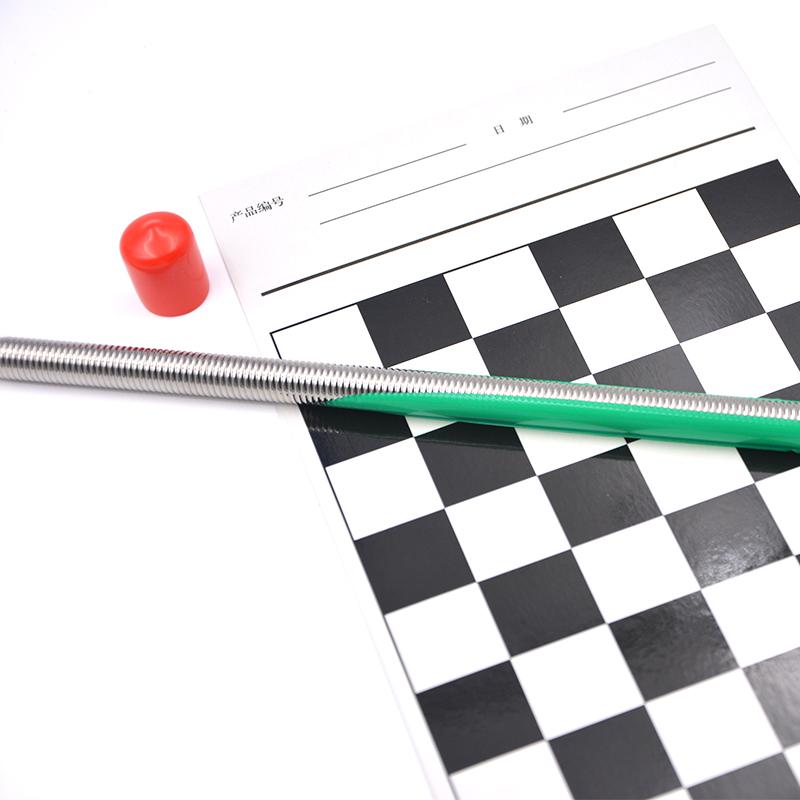

US RDS 2 #3/8 "Mayer Rods 4.6μm molding coating bar

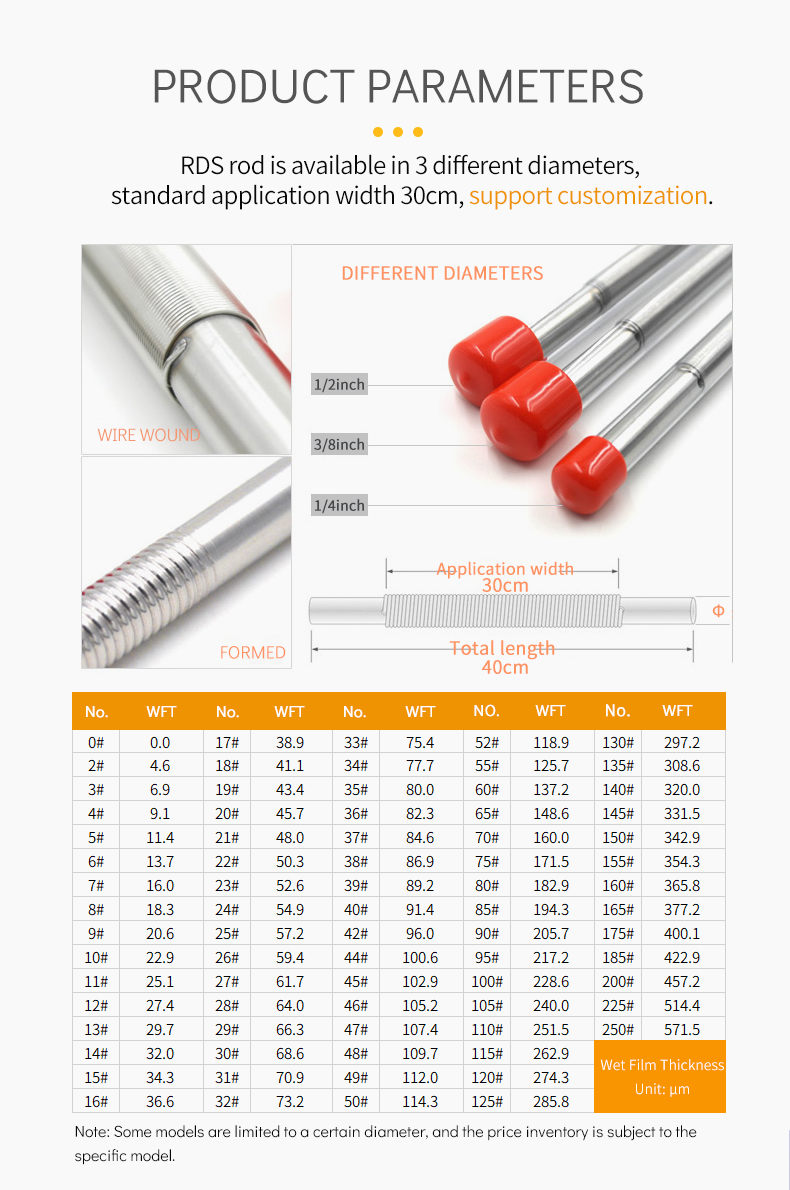

SEThe production process is formed, the wet film thickness is 4.6μm, the diameter is 9.52mm, the Total length is 400mm, the application width is 300mm, and the material is stainless steel.

$162.00/piece

PromotionLoading...

Coupon

Model:

Similar products

RDS 2# 3/8" Applicator rod 3/8 "SPEC

RDS 2# 3/8" Applicator rod 3/8 "Details

RDS 2# 3/8" Applicator rod 3/8 "Packing list

- SKU

- NB033840

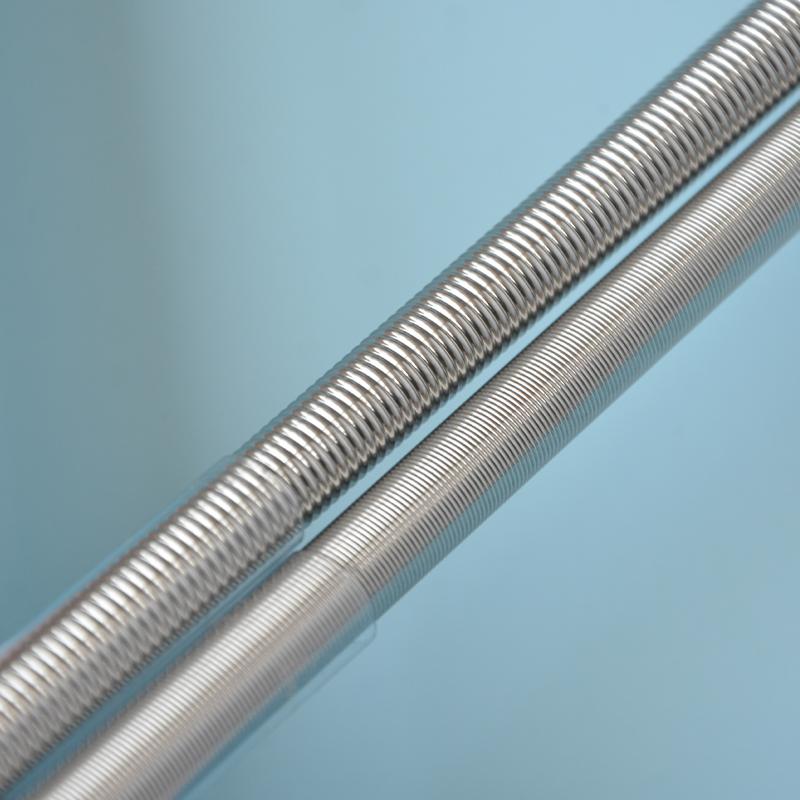

- Production process

- Formed

- WFT

- 4.6µm

- diameter

- 9.52mm

- Total length

- 400mm

- Application width

- 300mm

- material

- stainless steel

2# 3/8"

Applicator rod 3/8 "

The production process is formed, the wet film thickness is 4.6μm, the diameter is 9.52mm, the Total length is 400mm, the application width is 300mm, and the material is stainless steel.

Product description

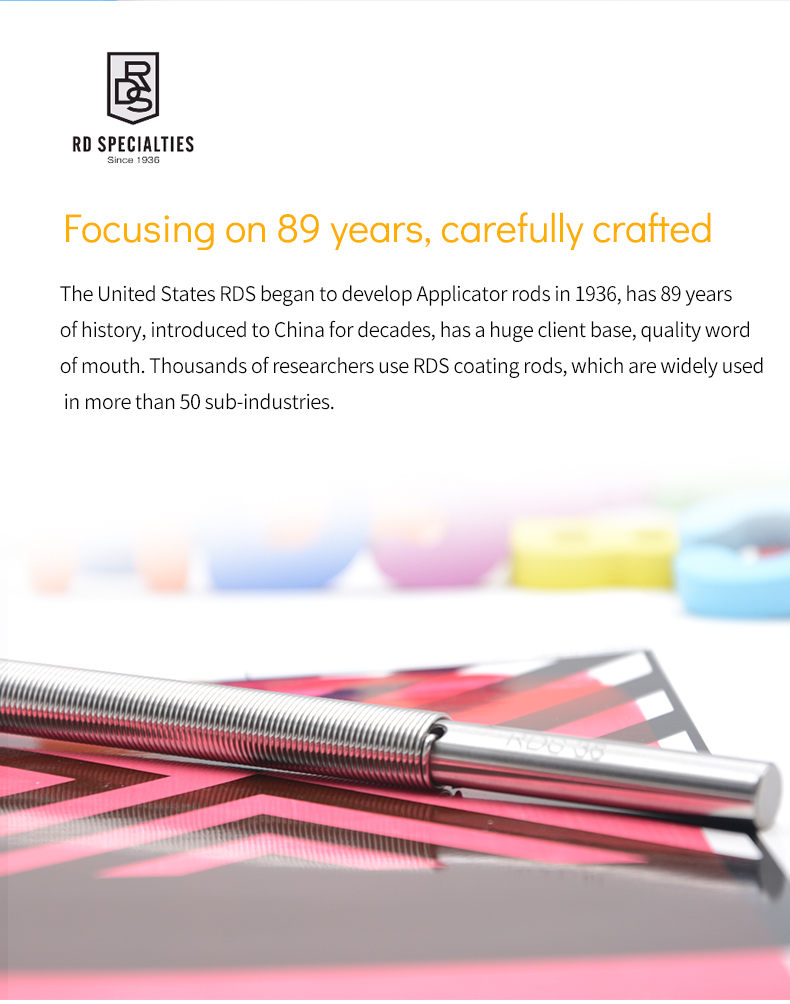

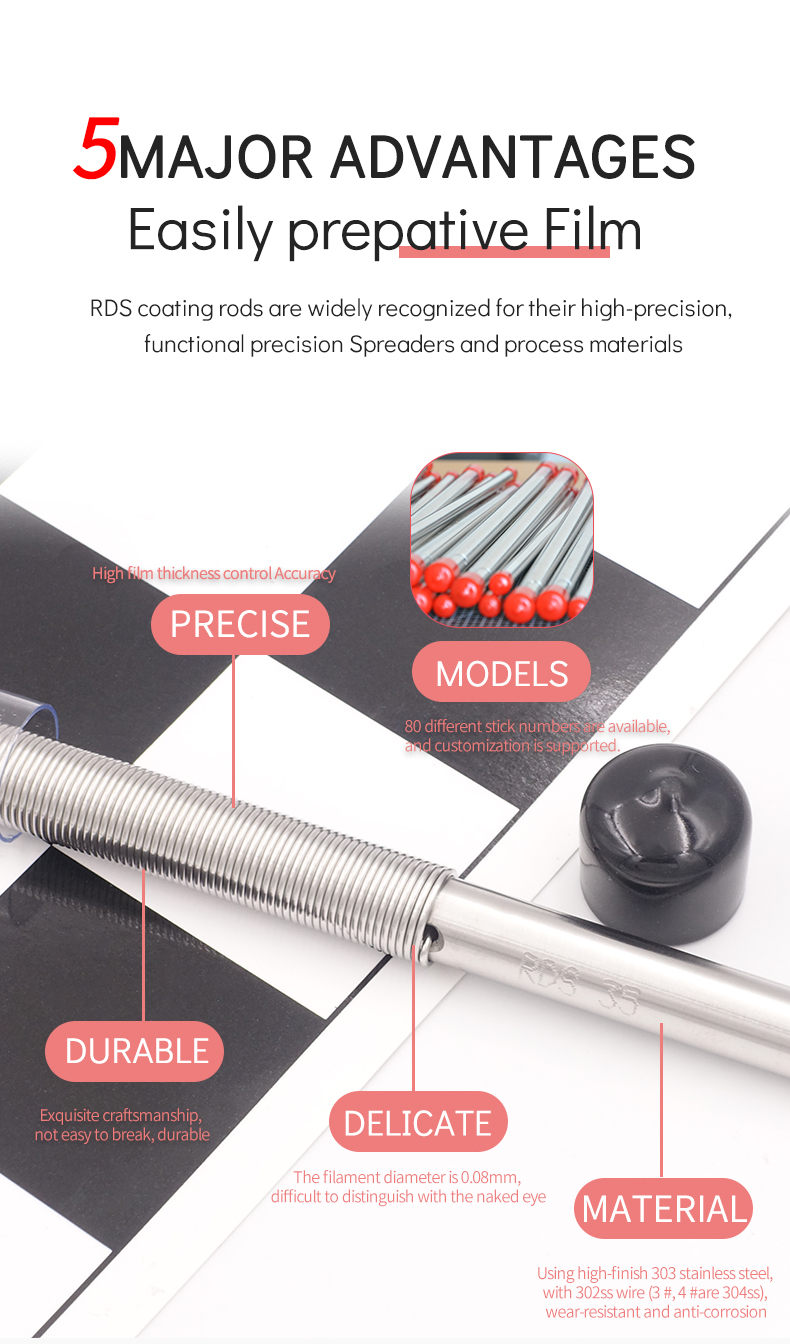

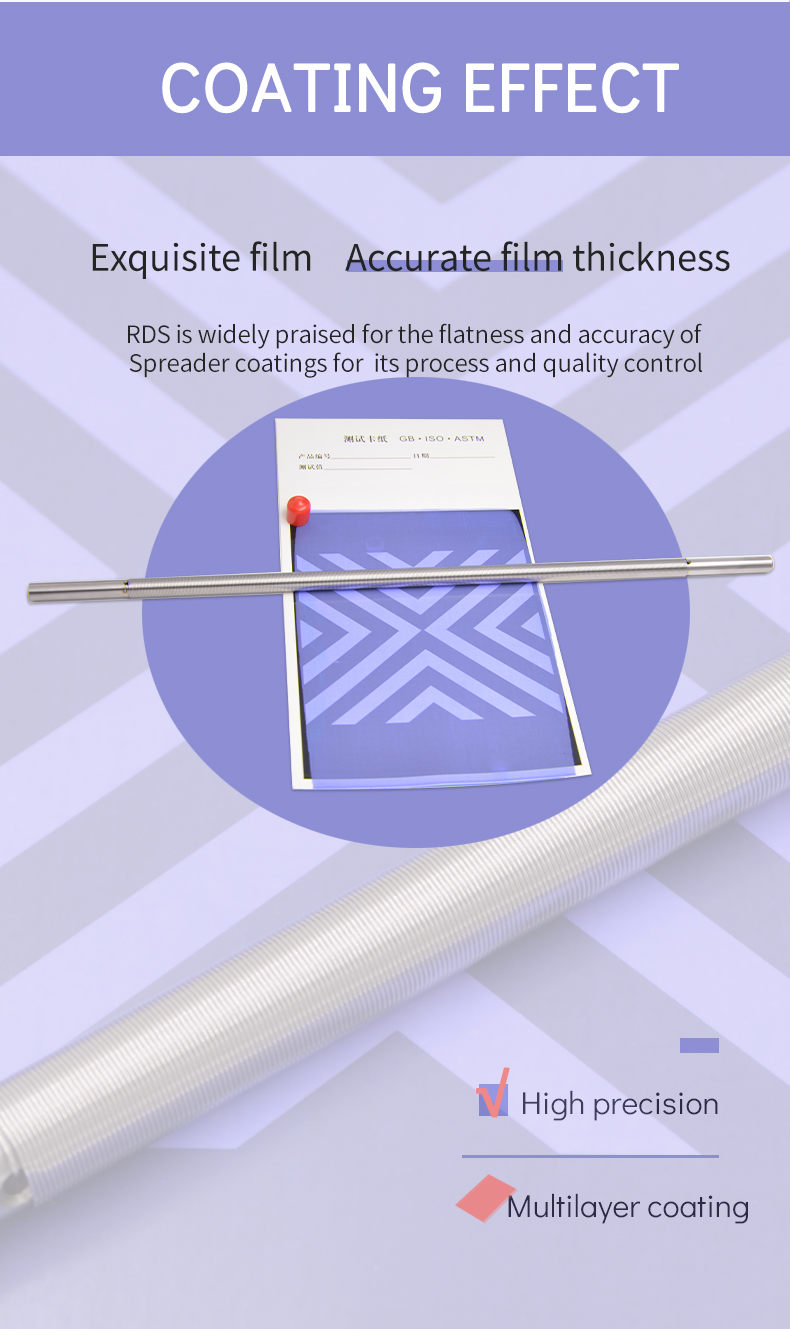

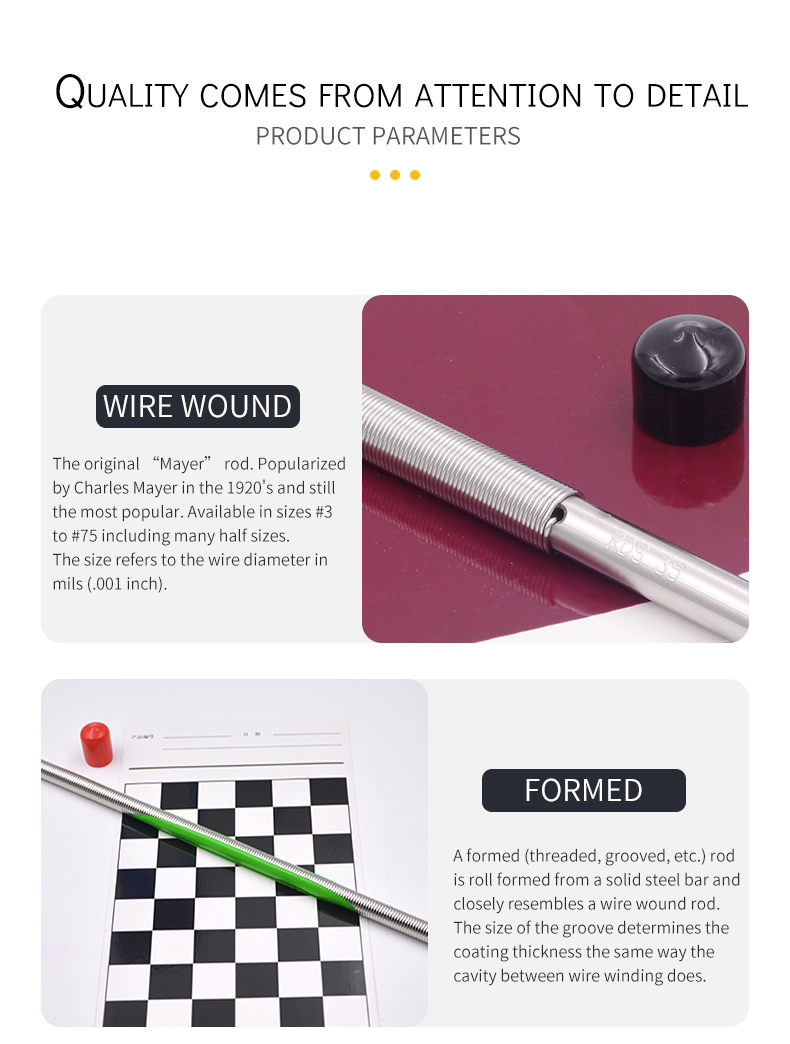

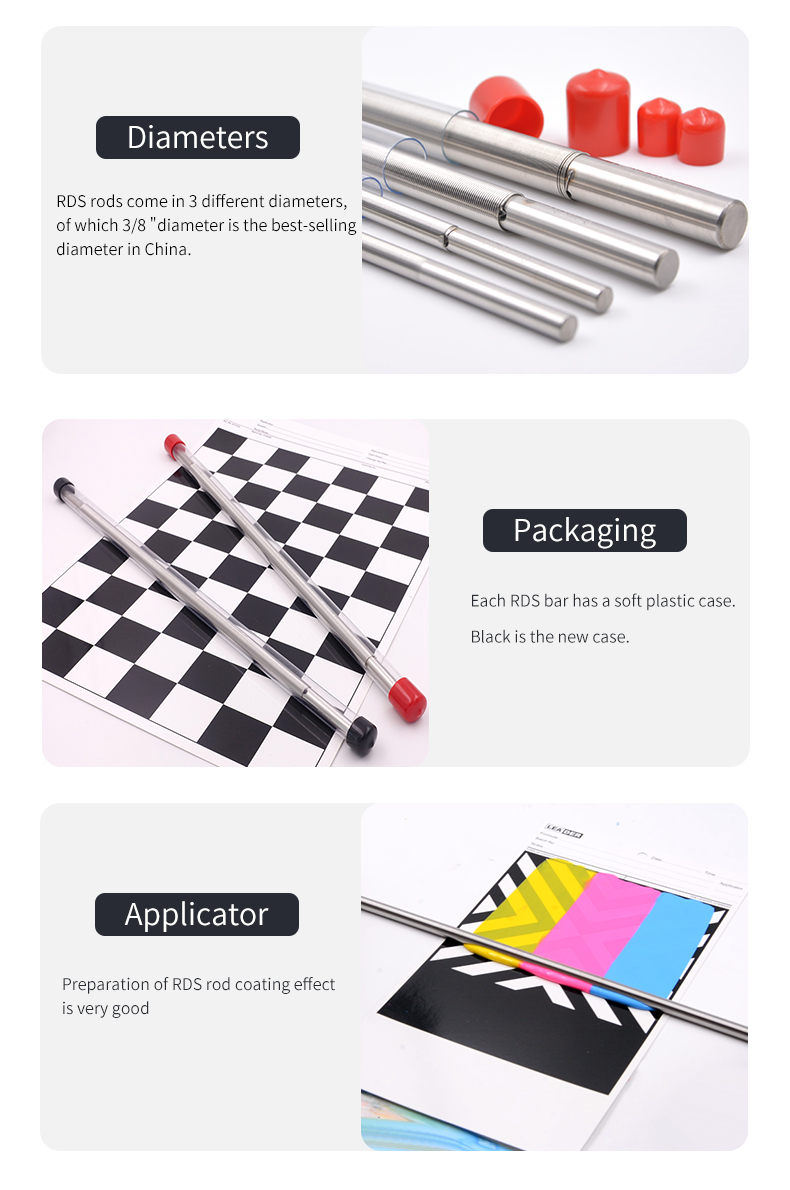

The RDS 2# 3/8" wire Bar Coater is a small-sized forming-type Applicator bar, and the thickness of the coating film is as thin as 4.6 μm, which can meet the needs of users for ultra-thin film coating. The RDS forming bar has the advantage of continuous wire , the coating precision is 0.1 micron, and the effective coating width is 30cm, which can be used with the laboratory automatic film coating machine. The RDS wire rod coater also has the wire rod coater of the wire-wound process, and the coating effect is the same as that of the forming rod it's the same.

FAQ

QI would like to ask what is the minimum Coating thickness of the RDS bar?

A

Stick number two, 4.6 microns.

QThe RDS doesn't have a No. 1 stick, right? The thinnest one is 4.6um, right?

A

Yes.

QCan RDS wire-wound drawdown bar be used in lithium battery paste scraping?

A

Sure.

QDoes RDS have a smaller rod number than rod 2?

A

And stick 0.

QCan RDS2 rod be prepative of 5 micron nano silicon oxide (nSiO2)?

A

Yes, ultra-thin film is recommended with Film Applicator to reduce errors such as manpower, scraping speed and pressure, and to prepare a more exquisite film.

QThe particle size of SiO particles is about 5μm. Can it be scraped out with this wire rod?

A

No, the No. 2 rod theoretically scrapes the film 4.6μm, and the particles with a particle size of 5μm cannot pass through the groove of 4.6μm, which will cause scratches. If you are sure to scrape 5 microns, you can grind the particles to finer. On the contrary, you need to choose a larger rod.

QCan RDS2 #Mayer Rods be installed on small Spreaders?

A

Hello, this one has a diameter of 6.35mm, which is not suitable. You can choose a 3/8 diameter one.

QIs there a wide-wounded RDS2 Applicator rod?

A

Hello, no, the No. 2 stick is only molded.

QWhat is the difference between the same 3/8 "diameter round Mayer-Rod and this molding rod? Can it be replaced?

A

The main difference between the Mayer-Rod and the molding rod is the different process of groove formation. The wire rods of the same specification and different processes can be replaced by each other, and the wet film thickness is the same. The difference is because the groove shapes of the two are different (the molding is U-shaped groove, and the winding wire is V-shaped groove). The calculation of the Spreader amount is different, and the relative molded Spreader amount will be more. There is no difference for laboratory use.

QMoulding rod is better for winding or extrusion?

A

In theory, the Moulding effect is the same. The extrusion U-groove is relatively easy to clean, but it requires high asperity on the inner wall of the groove. The winding follows the Mayer principle, and the scraping is smoother. If used for pre-production Measurement, the extrusion Spreader is larger than the winding. The same film thickness was prepared in the laboratory, and the effect was the same.

Knowledge

- 1Advantages of Bar Spreader in corrosion coating prepative

- 2One article introduces RDS Applicator rod type and FAQ

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 3GB/T 7044-2022《Colour carbon black》

- 4HG/T 5370-2018《Waterborne coatings for bicycles》

- 5HG/T 3951-2007《Water based colorants for architectural coatings》

- 6GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 7HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

2# 3/8"

2# 3/8"