LEEB MHBRVS-187.5 Touch screen digital display Blovey Hardness Gauge

Leeb MHBRVS-187.5 Touch screen digital Broway Hardness GaugeSPEC

Leeb MHBRVS-187.5 Touch screen digital Broway Hardness GaugeDetails

Leeb MHBRVS-187.5 Touch screen digital Broway Hardness GaugePacking list

- SKU

- NB034689

- Rock scale test force (test force tolerance: +/- 1.0%)

- HRA, HRB, HRC, HRD,HRE, HRF,HRG,HRH,HRK;60Kg (588N),100Kg (980.7N),,150Kg(1471N)

- Brinell scale

- HBW2.5/31.25, HBW2.5/62.5,HBW5/62.5, HBW2.5/187.5;30kgf(294.2N)、31.25kgf(306.5N)、62.5kgf(612.9N)、100kgf(980.7N)、187.5kgf(1839N)

- Vickers scale test force (test force tolerance: +/- 1.0%)

- HV30, HV100;30Kg(294.2N),100Kg (980.7N)

- The maximum allowable height of the test piece

- Test rockwell hardness: 185mm; test Brinell, Vickers hardness: 135mm

- Microscope magnification

- 37.5x、75x

- Load time

- 2~60S

- Distance from the center of the indenter to the fuselage

- 165mm

- Instrument size

- 520X240X700mm (, L W H)

- Instrument Weight

- About 85Kg

- Power

- AC220V±5%,50~60Hz

- Execution standards

- GB/T230.2 (Rockwell), GB/T231.2 (Brinell), GB/T4340.2 (Vickers), JJG112 (Rockwell), JJG150 (Brinell)

- lighting

- A Rockwell: not available; b Vickers built-in lighting: adjustable; c Brinell external lighting: not adjustable

Introduction

The HBRVS-187.5 digital display Burawoy Hardness Tester is a multi-purpose multi-functional hardness machine with three test methods: Brinell, Rockwell and Vickers, and seven levels of test force. It can meet the user's various hardness testing requirements. The application, holding and unloading of test force are completed automatically. It has a wide range of uses and is easy to operate. It is a hardness testing machine commonly used by industrial and mining enterprises and scientific research institutions.

The main function

Equipped with three test methods: Brinell, Rockwell and Vickers

A multi-purpose multi-functional hardness machine with seven levels of testing force, which can meet the user's various hardness testing requirements.

Rockwell hardness, Brinell and Vickers readings all have digital LCD display

The application, holding and unloading of test force are automatically completed

Wide range of use and easy operation

Application scope

Determine the Brinell, Vickers and Rockwell hardness of ferrous metals, non-ferrous metal carbide and non-metals. It has a wide range of applications and can be widely used for determination:

a. Brinell hardness of castings, annealed steel, normalized steel, non-ferrous metals and soft alloys;

b. Rockwell hardness of heat-treated materials such as quenching and tempering;

c. Vickers hardness of nitrided layer, ceramics, thin plates, metal sheets, electroplated layers, and tiny parts.

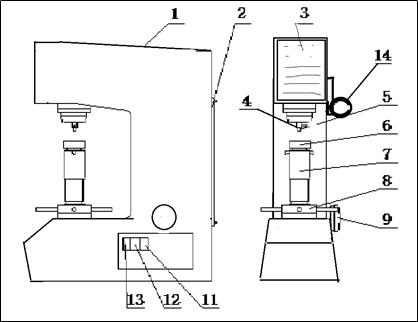

Host appearance

| 1. Upper cover | 2.Back cover | 3.Touch panel | 4. Pressure head locking screw | 5. Pressure head |

| 6. Test bench | 7.Lifting screw | 8.Wheel | 9. Variable load hand wheel | 11.Power socket |

| 12. Fuse | 13.Switch | 14. Bracket |

Standards compliant

GB/T 230.1-2018 Rockwell hardness test of metallic materials Part 1 Test methods

GB/T 230.2-2012 "Rockwell Hardness Test of Metallic Materials Part 2: Inspection and Calibration of Hardness Testers" National Standard

JJG 112-2013_Metal Rockwell Hardness Tester (A, B, C, D, E, F, G, H, K, N, âT scale) calibration procedures

ASTM E18-2015 Standard for Rockwell hardness test methods for metallic materials

ASTM Standard-Metal Test Methods and Analysis Procedures

GBT 231.1-2018 Brinell hardness test of metallic materials Part 1: Test method

GB/T 231.2-2012 Brinell hardness test of metallic materials Part 2: Inspection and calibration of Hardness Tester

GB/T4340.1-1999 GB/T 4340.1-1999 Metal Vickers hardness test Part 1: Test method

MHBRVS-187.5

MHBRVS-187.5