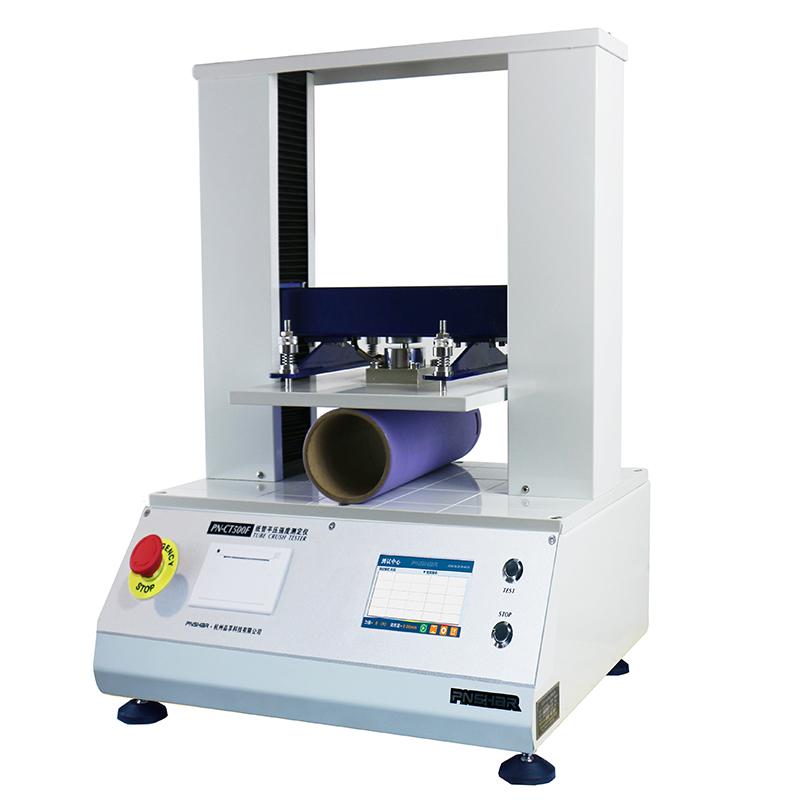

PNSHAR PN-CT500F Paper Tube Flat Compression Strength Tester

PNshar PN-CT500F Paper tube flat Compressive Strength TesterSPEC

PNshar PN-CT500F Paper tube flat Compressive Strength TesterDetails

PNshar PN-CT500F Paper tube flat Compressive Strength TesterPacking list

- SKU

- NB034778

- Power

- (100~240)VAC 2A 50/60Hz

- Error of indication

- ±1%

- Indication variability

- <1%

- Resolution

- 0.1N

- Force range

- 25~5000N

- deformation error

- ≤ ±0.1mm

- Plate size

- 300*300mm

- Plate parallelism

- ≤ 0.6mm (platen length * 0.2%)

- Working Travel

- 10~350mm

- Pressurization speed

- 60 +/- 1mm/min (1~ 120mm/min can be set)

- return speed

- 5~150mm/min

- monitor

- 7 "Color touchscreen

- printout

- modular integrated thermal printer

- Communication interface

- RS232 (std.)/USB (optional)

- Operating Environment

- Indoor temperature (20 +/- 10) ℃; Relative Humidity < 85%

- Dimensions

- 535*425*805mm

- Weight

- About 81kg

Introduction

PN-CT500F paper tube flat crush strength Tester is a paper tube flat crush strength testing instrument designed and developed by our company in accordance with the national standards GB/T 22906.9, BB/T 0032 and ISO110939.9. It is mainly suitable for all types of industrial paper tubes. , chemical fiber paper tubes, small packaging boxes and other types of small containers, compressive strength and deformation detection. It is a satisfactory testing equipment for paper tube manufacturers, quality inspection agencies and other departments.

Paper tube flat compression strength: radial pressure per unit length, expressed in kN/m. If the inner diameter is not greater than 300mm, the sample length should be 100mm; if the inner diameter is greater than 300mm, the sample length should be 300mm.

The instrument has an electromechanical integration structure. It adopts modern mechanical design concepts and microcomputer processing technology for careful and reasonable design. The instrument adopts a movable upper platen and a fixed lower platen. It has powerful data processing functions, which can directly obtain statistical results of various data, and has a pressure curve display function.

This instrument has three standard Operating Modes:

1. Compression test

2. Fixed value test

3.Stacking test

The paper tube flat compression strength only uses the "Compression Test" mode, input the test speed and sample length, and test with one click. After the test, the screen displays the paper tube pressure resistance, deformation, and paper tube flat compression strength values.

Implementation standards

GB/T 22906.9, ISO 110939.9, BB/T0032

Features

1. Adopt new module circuit design, with WIFI Internet of Things function. After being connected to the Internet, the test results can be saved to the cloud server, and can be queried and generated through the dedicated QMS quality management system;

2. Large compression stroke, 350mm;

3. After testing, return at high speed to improve testing efficiency;

4. It adopts double screw and double guide column mechanical structure, with good parallelism, good stability, strong rigidity and long service life;

5. It adopts ball screw transmission structure and has high transmission efficiency;

6. It adopts imported stepper motor control and uses subdivision technology to achieve accurate positioning and fast response, which saves test time and improves test efficiency.

7. Can display pressure and deformation curves, and display resistance to pressure and deformation in real time;

8. It has statistical functions, showing the average value, maximum value, minimum value, standard deviation and coefficient of variation;

9. Optional PC software specially provided by our company facilitates data processing.

PN-CT500F

PN-CT500F