Muxuan MXR-2.2-3 laboratory three-stage emulsification pump 2200W

SEMuXuan MXR-2.2-3 Laboratory three-stage emulsification pumpSPEC

MuXuan MXR-2.2-3 Laboratory three-stage emulsification pumpDetails

MuXuan MXR-2.2-3 Laboratory three-stage emulsification pumpPacking list

- SKU

- NB034816

- power

- 2.2kw

- Speed range

- 3000rpm

- input Voltage

- 380/220V

- Standard throughput

- 5~100L

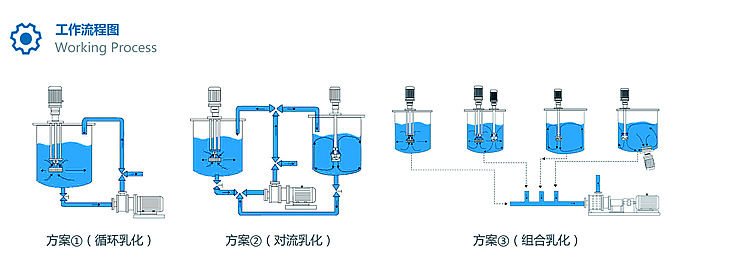

Equipment introduction

Three sets of rotating stators are installed in the working chamber of the three-stage pipeline emulsification pump in the laboratory. The rotating and stators can be configured in a single layer, two layers to six layers. In the working chamber, in the process of the material from the suction port to the discharge port, it has been dispersed, sheared and emulsified by multi-stage multi-layer rotors for many times, and has been circulated, continuously dispersed, sheared and emulsified to achieve stable high-quality product. It is suitable for mixing, dispersing, dissolving and emulsifying of liquid or miscible materials.

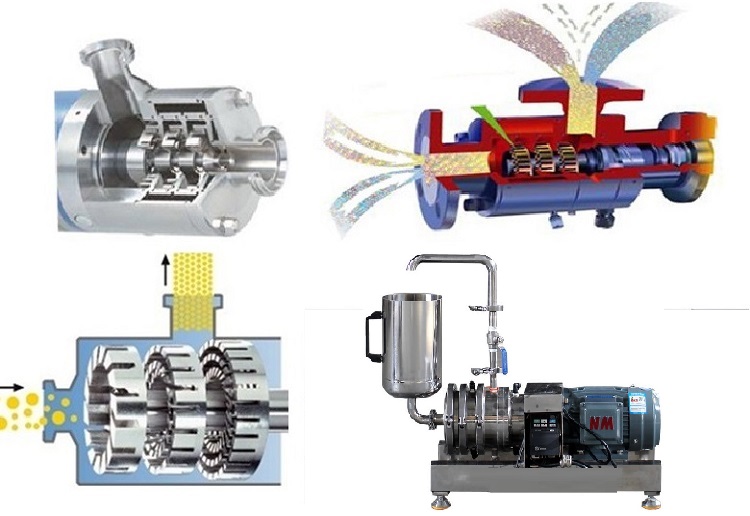

Principle

The three-stage emulsification pump in the laboratory adopts a horizontal structure; three sets of rotor stators are installed in the narrow and long working chamber, and the intermediate shaft is driven by the motor to run at high speed. The rotor stator forms a vacuum, and the material is sucked into the rotor stator cavity from the double-layer material barrel , the strong kinetic energy makes the rotor produce a higher linear speed, so that the material will fly out after strong impact, crushing, centrifugal extrusion, liquid layer friction, and shearing between the rotor and the stator gap. Under the condition of strong turbulent flow, the material flows out from the outlet and enters the Mixing Tank for circulation, so that the immiscible solid phase, liquid phase, gas and other media are uniformly fine, dispersed and emulsified in an instant, so that the product reaches a stable high Quality product.

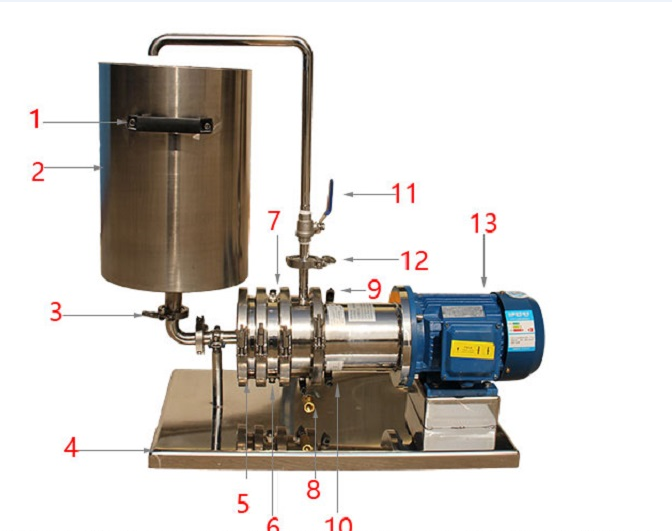

equipment structure

1 barrel handle/2 barrel (5-20L)/3 barrel quick release clip/4 stainless steel bottom plate (casters optional)/5 quick release maintenance clip/6 jacket cooling inlet (optional)/7 clamp Sleeve cooling outlet (optional) / 8 blowdown valve / 9 machine seal cooling outlet / 10 machine seal cooling inlet / 11 discharge valve / 12 outlet 360 degree adjustment clamp / 13 motor (explosion-proof or non-explosion-proof)

Application

【Material viscosity】:≤20000 cps

【Production capacity】: single 5-20L

[Applications]: It is suitable for dispersing, emulsifying and homogenizing product materials in industries such as biology, medicine, food, paint, ink, textile auxiliaries, cosmetics, lubricants, and pesticides.

[Applicable materials]: It can be used in the process of mixing solid and liquid, liquid and liquid to form a solution, colloid, suspension or emulsion; such as juice, soup, dairy homogenate, cosmetics, surfactants, asphalt , emulsifiers, oilfield chemicals.

Advantages

Easy to operate

Self-contained circulation barrel, good conveying capacity, convenient solvent self-circulation cleaning, no need for additional conveying pump, double-layer cooling barrel, low temperature rise of the equipment.

High experimental efficiency and stable product quality

The line speed of the equipment is above 20m/s, which can quickly distribute one phase uniform material to another or multiple materials to achieve the effect of fine homogeneity, dispersion and emulsification, and the product is stable and not easy to delaminate.

High processing precision

The rotor stator is made of forging material and processed by CNC. The rotor stator gap is small, the shearing fineness is good, the emulsification and dispersion efficiency is high, and the double-end mechanical seal design is adopted, which has no leakage and reduces maintenance costs.

Strong non-standard

The material can be customized according to the requirements of unconventional materials such as SS304, SS316L/titanium alloy/titanium-molybdenum-nickel alloy; explosion-proof equipment can be customized, and frequency conversion speed regulation is optional.

MXR-2.2-3

MXR-2.2-3