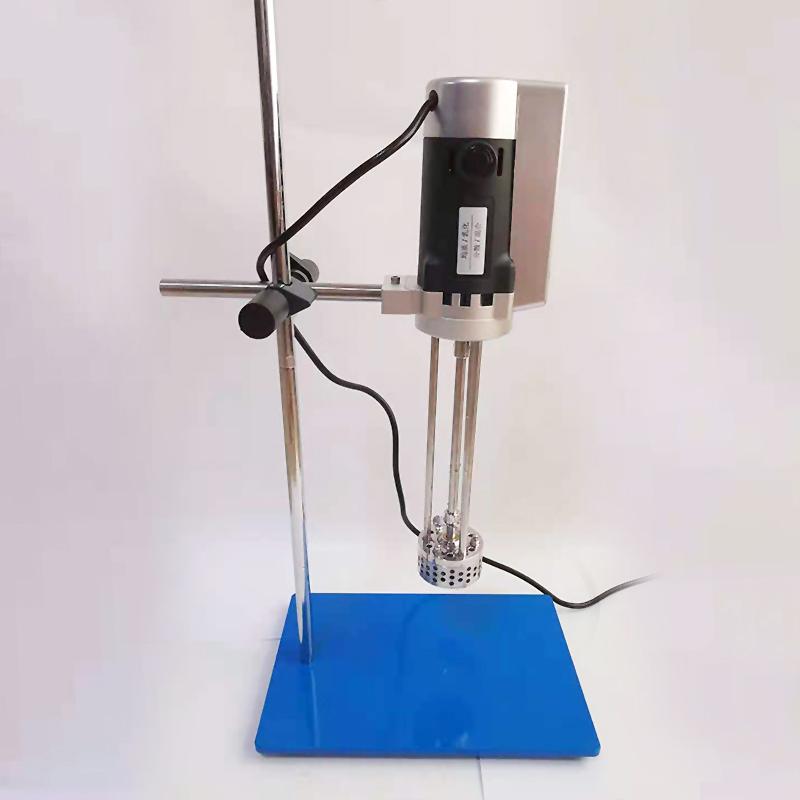

MUXUAN ZN500-12 Laboratory High Shear Mulser Work Head 12G

MuXuan ZN500-12 Laboratory High Shear MulserSPEC

MuXuan ZN500-12 Laboratory High Shear MulserDetails

MuXuan ZN500-12 Laboratory High Shear MulserPacking list

- SKU

- NB034817

- Rated Voltage

- AC 220V 50/60 Hz

- output power

- 500W

- Speed range

- 1000~28000rpm

- Rotation speed display

- TFT-LCD

- Timer

- 1-1000 min

- Rotation speed dynamic detection function

- Yes

- Overload protection

- Yes

- Real-time torque Linear dispersion display

- Yes

- Real-time Voltage, Current, Frequency, Power Display

- Yes

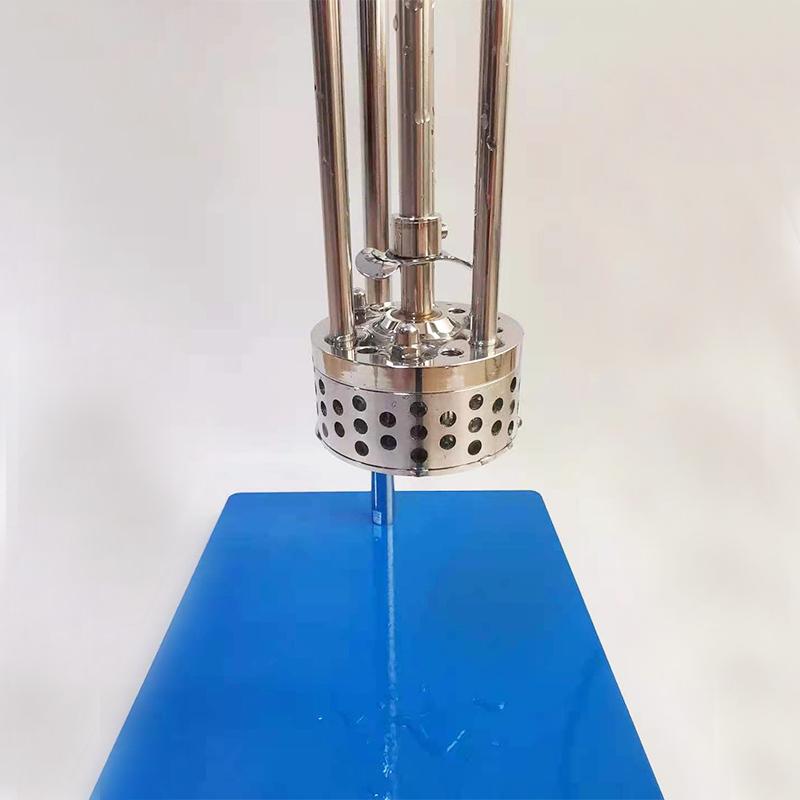

- Work head material

- Stainless steel 316L #

- Work head specification

- 12/18/25/30/36G (standard 25G)

- Ambient Temperature

- Not more than 40 ℃

- Allowable Relative Humidity

- Not more than 80%

- Dimensions

- 215*310*720 mm

- Machine Weight

- Approx. 9.2kg (Gross Weight: 11.0kg)

- Work head specification

- 12G

- Processing Capacity

- 30~800mL

- Max. Processing Viscosity

- 1000cp

- Rotor maximum linear velocity

- 12m/s

- Maximum immersion liquid height

- 150mm

- stator diameter

- 12mm

- Operating temperature(MAX)

- 120℃

- Work head material

- SS316

- Bearing material

- PTFE

- Minimum immersion liquid height

- 35mm

Equipment introduction

High-speed motor, optionally equipped with a variety of working heads, with speeds up to 28,000rpm and line speeds up to 27m/s

Triple-core processor intelligent control motherboard, 2.8-inch TFT true color touch screen, real-time Voltage, frequency, current, and power display. Equipped with torque curve display, the experimental data is more accurate. It has overload and overcurrent protection, local self-test, timing, memory and other functions. The speed can be preset and paused at any time. The speed is digitally displayed and easy to operate.

Application scope

[Material viscosity]: â¤8000 cps (mPas)

[Application fields]: Suitable for dispersion, emulsification and homogenization of product materials in industries such as biology, food, coatings, inks, textile auxiliaries, cosmetics, lubricants, pesticides and other industries.

[Applicable materials]: Solids and liquids, liquids and liquids can be mixed to form solutions, colloids, suspensions or emulsions; such as juices, soups, dairy products, tissue homogenates, cosmetics, surfactants, Asphalt, emulsifiers, oil field chemicals and other materials.

Applicable process

Depending on the working head it is equipped with, it can complete a variety of different processes, including dispersion, emulsification, homogenization, grinding, mixing, dispersion and homogenization of high-viscosity materials, crushing and homogenization of animal and plant tissues, etc.

Features

Triple-core processor intelligent control motherboard, 2.8-inch TFT true color touch screen, real-time Voltage, frequency, current, and power display. Equipped with torque curve display, the experimental data is more accurate. It has overload and overcurrent protection, local self-test, timing, memory and other functions. The speed can be preset and paused at any time. The speed is digitally displayed and easy to operate.

It integrates dexterity, convenience, and high scalability. The whole machine has a modular structure, is easy to operate, and can run for a long time. It can easily meet a variety of high-demand dispersion and emulsification experiments and enjoy the fun of dispersion and emulsification in the laboratory.

ZN500-12

ZN500-12