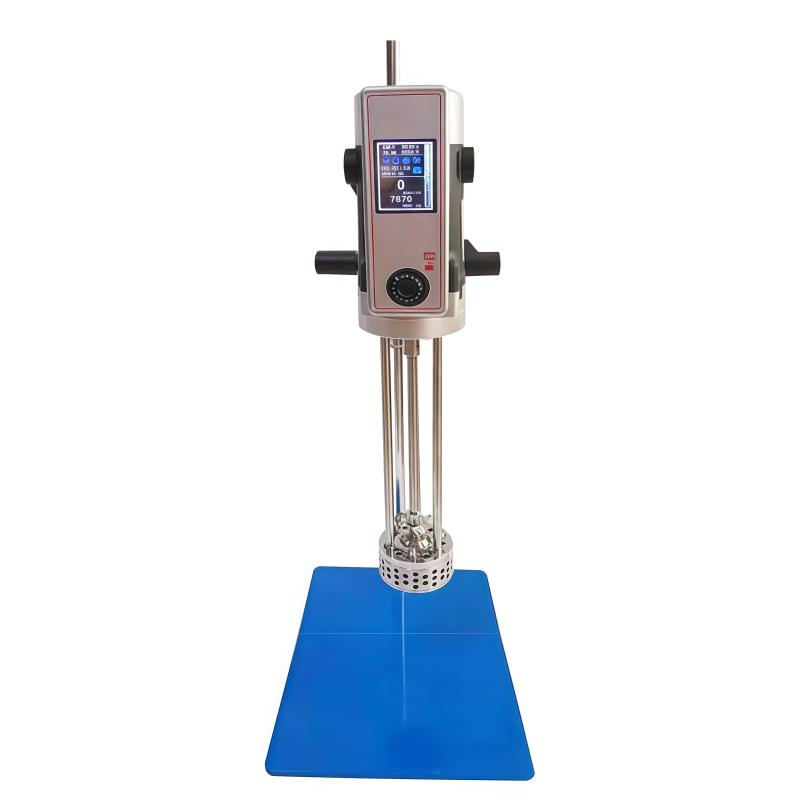

MUXUAN ZN500-70 Laboratory High Shear Mulser Tri-Core Processor Intelligent Control 20.5m/s Line Speed

SEMuXuan ZN500-70 Laboratory High Shear MulserSPEC

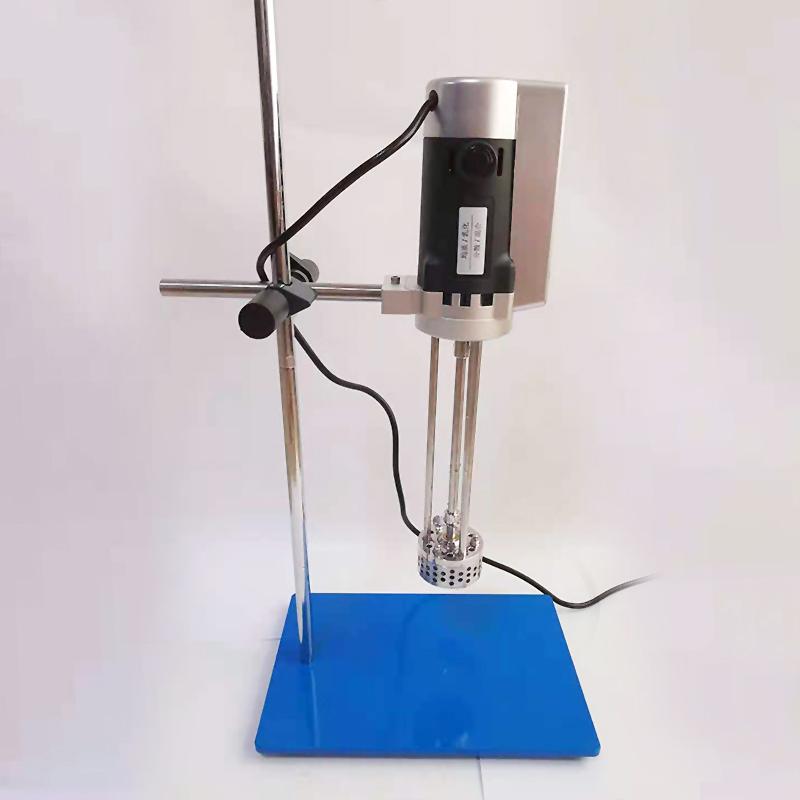

MuXuan ZN500-70 Laboratory High Shear MulserDetails

MuXuan ZN500-70 Laboratory High Shear MulserPacking list

- SKU

- NB034823

- Rated Voltage

- AC 220V 50/60 Hz

- output power

- 500W

- Speed range

- 1000~14000rpm

- Speed display

- TFT-LCD

- Timer

- 1-1000 min

- Speed dynamic detection function

- Yes

- Overload protection

- Yes

- Linear dispersion display

- Yes

- Real-time Voltage, current, frequency, power display

- Yes

- Rotor maximum linear speed

- 20.5 m/s

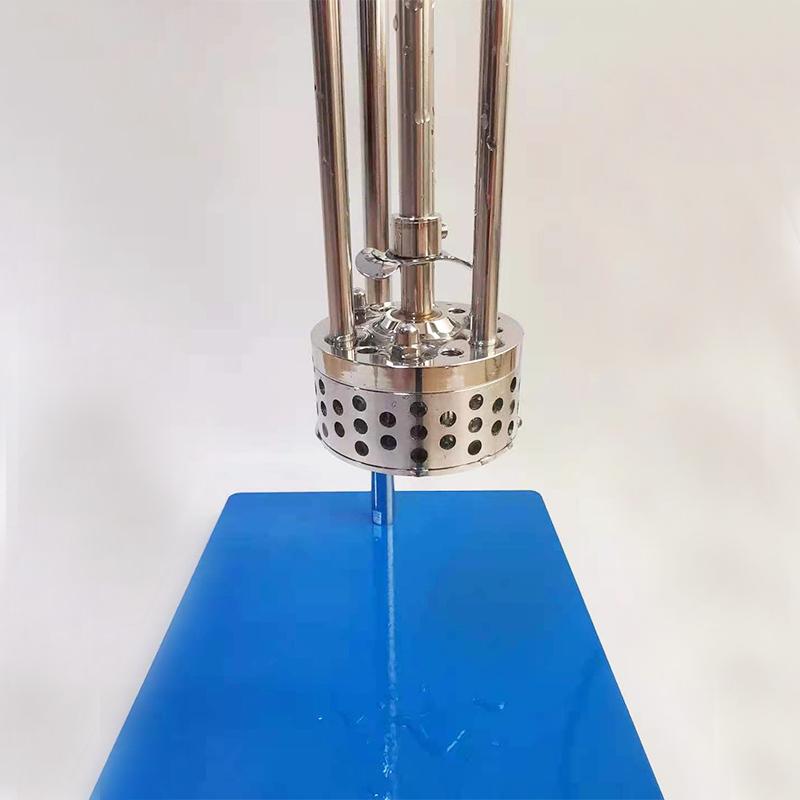

- Work head material

- Stainless steel 304/316L #

- Work head specification

- F70 mm

- Maximum immersion liquid height

- 50mm

- Stator standard configuration

- Round hole, one long hole working head each

- Standard throughput

- 500~10000mL

- Maximum Max. Viscosity

- 8000 mPa.s

- Allowable environment temperature

- Not more than 40 ℃

- Allowable Relative Humidity

- Not more than 80%

- Dimensions

- 215*310*720 mm

- Minimum immersion liquid height

- 50mm

Equipment introduction

The laboratory homogeneous emulsifier is a laboratory equipment designed for laboratory micro experiments. Through the method of mechanical external force, the particle size of liquid-liquid and solid-liquid materials is narrowed, so that one phase is evenly distributed into another or multiple phases, so as to achieve the effect of refinement, homogeneity, dispersion and emulsification, thus forming a stable The state of liquid-liquid and solid-liquid dispersion systems. Can be equipped with a variety of working heads of different specifications

Application

【Material viscosity】:≤8000 cps(mPas)

[Applications]: It is suitable for dispersing, emulsifying, and homogenizing product materials in industries such as biology, medicine, food, paint, ink, textile auxiliaries, cosmetics, lubricants, and pesticides.

[Applicable materials]: It can be used in the process of mixing solid and liquid, liquid and liquid to form a solution, colloid, suspension or emulsion; such as juice, soup, dairy products, tissue homogenate, cosmetics, surfactants, Asphalt, emulsifier, oilfield chemicals and other materials.

Applicable process

It is suitable for dispersing, homogenizing, emulsifying, pulverizing, polymerizing, suspending and dissolving materials with medium viscosity and above.

native features

Tri-core processor intelligent control motherboard, 2.8-inch TFT true-color touch screen, real-time Voltage, frequency, current, power display. With torque curve display, the experimental data is more stable, with overload and overcurrent protection, local self-test, timing, memory and other functions, the speed can be preset, pause at any time, the speed is digitally displayed, and the operation is convenient.

Principle

The powerful motor of the laboratory homogeneous emulsifier rotates at high speed to form a vacuum between the rotor and the stator, and the material is sucked from the upper and bottom of the rotor and stator. The strong kinetic energy makes the rotor produce a higher linear speed, so that the material is thrown out after strong impact, crushing, centrifugal extrusion, liquid layer friction, and shearing between the rotor and the stator gap. , resulting in strong turbulence. Under the appropriate amount of emulsifier and mature technology, the material undergoes repeated depolymerization, dispersion, homogenization, refinement and shearing to produce a stable emulsion after a certain period of time.

ZN500-70

ZN500-70