MODERNER GFJ-1.5 variable speed Stirrer explosion-proof motor, variable frequency speed regulation, pneumatic lift

SEModerner GFJ-1.5 Variable Speed Stirrer (Explosion Proof)SPEC

Moderner GFJ-1.5 Variable Speed Stirrer (Explosion Proof)Details

Moderner GFJ-1.5 Variable Speed Stirrer (Explosion Proof)Packing list

- SKU

- NB034884

- Speed range

- 0~1200rpm

- Speed regulation mode

- Frequency conversion speed regulation

- gas source

- 0.4~ 0.6 MPa clean air

- explosion-proof

- Motor explosion-proof

- Main Motor Power

- 1.5kw

- Impeller configuration

- Φ100/Φ150mm

- Lifting stroke

- 500mm

- Dimensions of the whole machine

- 800*800*850mm

- Machine Weight

- 100kg

Overview

GFJ-1.5 variable speed mixer can be used for mixing, dissolving or dispersing liquid materials, and is widely used in the test and trial production of chemical products such as coatings, inks, adhesives, etc., with the characteristics of simple structure, flexible use and convenient cleaning. Explosion-proof motor, frequency conversion speed regulation, dispersion shaft lifting pneumatic control, dispersion blades made of stainless steel.

Structure

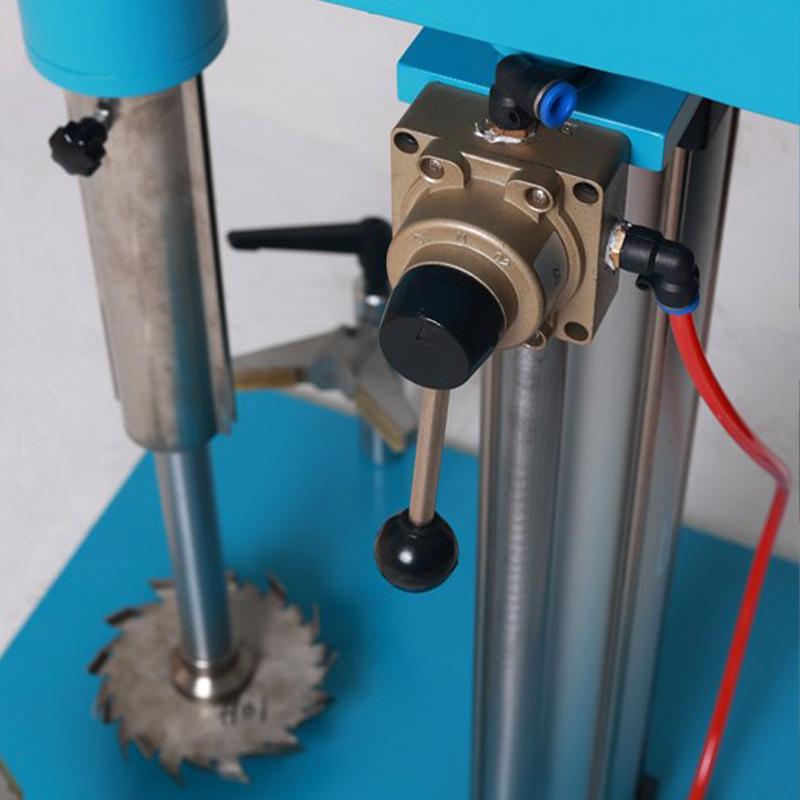

1. Pneumatic lifting column:

Consists of cylinders with guides. The cylinder adopts a double-acting cylinder with cushioning, and the user provides a clean air source. The three-position four-way manual reversing valve is used to control the upward and downward movement of the cylinder.

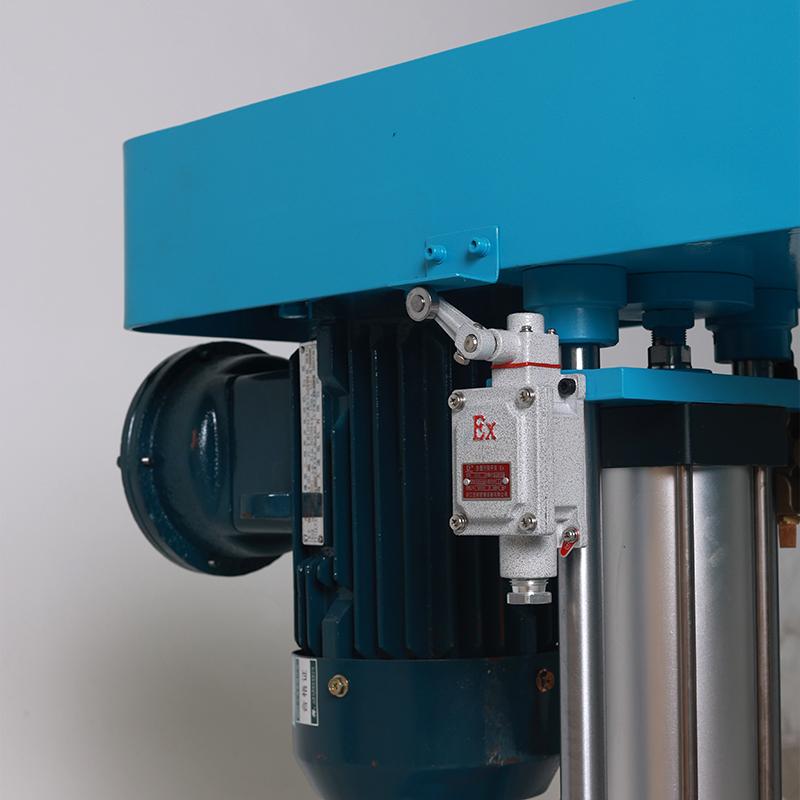

2. Transmission device:

The main motor is fastened to the transmission housing, and is driven by a V-belt pulley to drive the dispersion shaft to rotate.

3. Dispersion impeller device:

The dispersion impeller is composed of a combination of blades and upper and lower flanges, both of which are made of stainless steel.

Empty vehicle test

(1) Pre-drive inspection:

1. Check the tightness of the triangle tape and adjust it appropriately. There is no debris in the transmission box.

2. Gently rotate the dispersion shaft by hand, which should rotate flexibly.

(2) Commissioning:

1. The handle of the reversing valve is pulled forward (close to the direction of the body), and the cylinder begins to rise. The handle returns to the center and the cylinder stops. Gradually raise the cylinder to the highest point and stop, and make sure that the cylinder movement is smooth and unhindered during the whole process. Then the handle is pulled back so that the cylinder is lowered. When the descent is over, return the handle to the center. After passing the inspection several times, proceed to the next step.

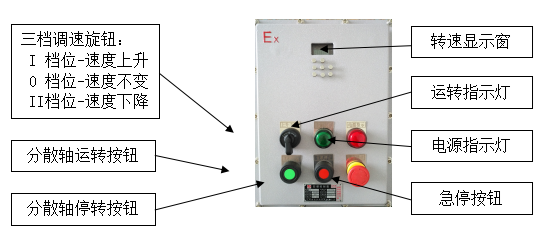

2. If the "Emergency Stop" button is pressed, release the "Emergency Stop" button first. Then press the "start" button of the control box, adjust the speed of the dispersion shaft with the three-speed knob (so that the motor rotates low), and observe whether the steering is correct (from top to bottom, the impeller should rotate clockwise). After 5~10 minutes of low-speed operation, the speed is adjusted to high-speed operation for 30 minutes, the temperature rise of the bearing is less than 30 °C, there is no channeling phenomenon of the shaft, and there is no noise of the whole machine. After passing the empty inspection, the physical test can be carried out. Press the "stop" button of the control box to stop the motor operation. The speed can be easily changed by a three-speed knob.

Control button description

Maintenance and precautions

1. Keep the air supply clean. Properly lubricate moving parts

2. If the equipment is not used for a long time, it should be maintained. Lubrication of all moving parts is protected.

3. The length of the new triangle tape should be consistent to avoid uneven force.

4. The equipment has a lifting limit control, and the dispersion shaft can only start the operation of the dispersion shaft when it is lowered to the lowest point.

5. After the end of the dispersion operation, please press the "emergency stop" button before changing the barrel or cleaning and other operations, which can avoid accidentally touching the "start" button to accidentally open the dispersion shaft rotation.

6. This machine is used in the test process of chemical raw materials, and the user should establish appropriate safety and protective measures and determine the rules and regulations according to the relevant safety regulations before use. Safety issues related to contact with chemical raw materials shall be established by the user and shall not fall within the scope of this manual.

GFJ-1.5

GFJ-1.5