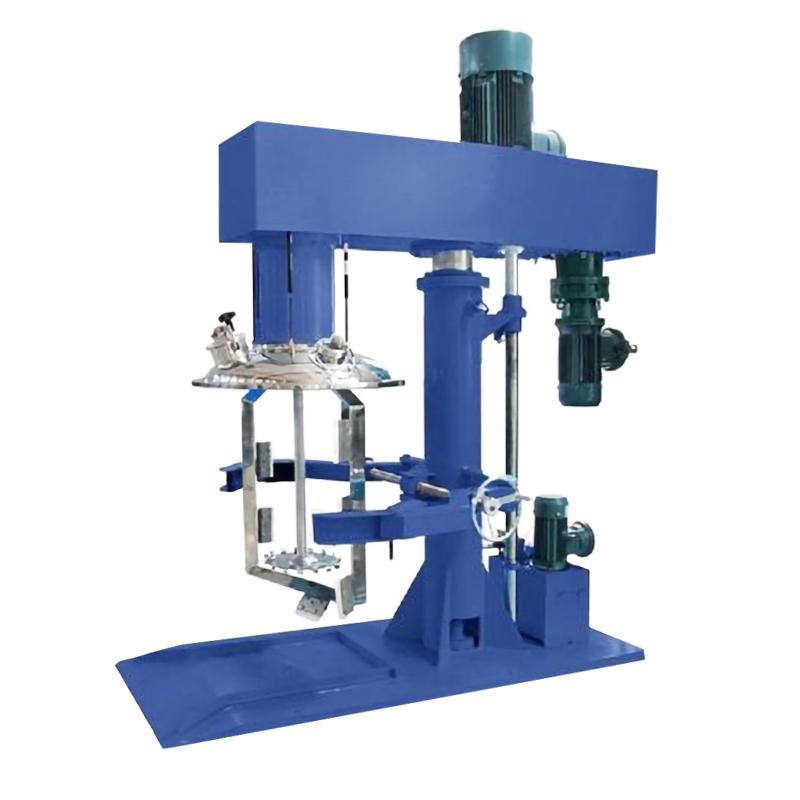

MUXUAN MXF-T500 Concentric Double Axis Hydraulic Disperser 500L/22kw

MuXuan MXF-T500 Concentric Double Shaft Hydraulic DisperserSPEC

MuXuan MXF-T500 Concentric Double Shaft Hydraulic DisperserDetails

MuXuan MXF-T500 Concentric Double Shaft Hydraulic DisperserPacking list

- SKU

- NB034978

- Distributed Power

- 22kw

- Processing Capacity

- 500L

- Rotation speed

- 0~1500rpm

- Mixing Power

- 7.5kw

- Rotation speed

- 25rpm

Introduction to the device

MXF-T series hydraulic lifting high-low speed power mixing and dispersing machine concentric twin shaft multi-functional dispersion mixer is a product with dispersion and mixing function developed on the basis of hydraulic lifting single shaft mixer, which is divided into independent double shaft and concentric twin shaft according to whether the twin shaft is concentric design; Frame type, etc., dispersion and stirring can be carried out at the same time, with strong adaptability, and can be customized according to the characteristics of the customer's materials and production process requirements.

Operating Principle

The stirring blade is driven by the power unit to rotate in a fixed direction, and in the process of rotation, the material is driven to rotate in the axial and radial directions. The material in the mixer has both axial motion and circular motion, so there are several mixing forms such as shear stirring and diffusion stirring at the same time. The scraper is equipped on the mixing paddle, which is scraped close to the barrel wall, and the scraper completely scrapes off the material on the barrel wall when the agitator rotates, so that the barrel wall has no trapped material, and the mixing effect is improved at the same time. Through high-speed operation, the dispersion disc makes the material flow in a circular shape, generating a strong vortex that descends to the bottom of the vortex in a spiral shape. Strong shear impact and friction are generated between the particles to achieve rapid dispersion and dissolution. The mixing disc through circular motion, produces a good radial effect, accelerates the material circulation, improves the dispersion efficiency, the hydraulic lifting mixer drives the hydraulic plunger to lift through the hydraulic pump work, and drives the entire transmission mechanism and working group to lift.

Advantages

1. High mixing efficiency

The double-shaft multi-functional dispersion mixer is composed of a scraping wall agitator and a high-speed disperser, and the two groups of agitators work at the same time to make the material subject to strong shearing and mixing action to achieve the purpose of rapid mixing; the agitator is generally divided into two types: anchor type and butterfly type, and different mixing forms can be designed for materials with different viscosity and specific gravity and different production process requirements.

2. The material does not stick to the wall and the discharge is clean

The agitator is equipped with a scraper, scraped close to the barrel wall, and the barrel wall is polished by an automatic polishing machine after being finished by a vertical lathe, so as to ensure that the material on the barrel wall is completely scraped off when the movable scraper rotates, so that the barrel wall has no retained material and improves the mixing effect.

3. Strong non-standard

Various types of non-standard products can be customized, such as explosion-proof type, vacuum type, heating type, intelligent type with PLC control, and the material can be customized according to the requirements of SS316L stainless steel or sprayed special materials.

Comparison of parameters of MXF-T series hydraulic disperser

| Model | Disperse power kw | Dispersion of RPM | Stirring power kw | Stirring speed rpm | Throughput L |

| MXF-T300 | 15 | 0-1500 | 5.5 | 40 | 300 |

| MXF-T 500 | 22 | 0-1500 | 7.5 | 25 | 500 |

| MXF-T1000 | 37 | 0-1500 | 11 | 25 | 1000 |

MXF-T500

MXF-T500