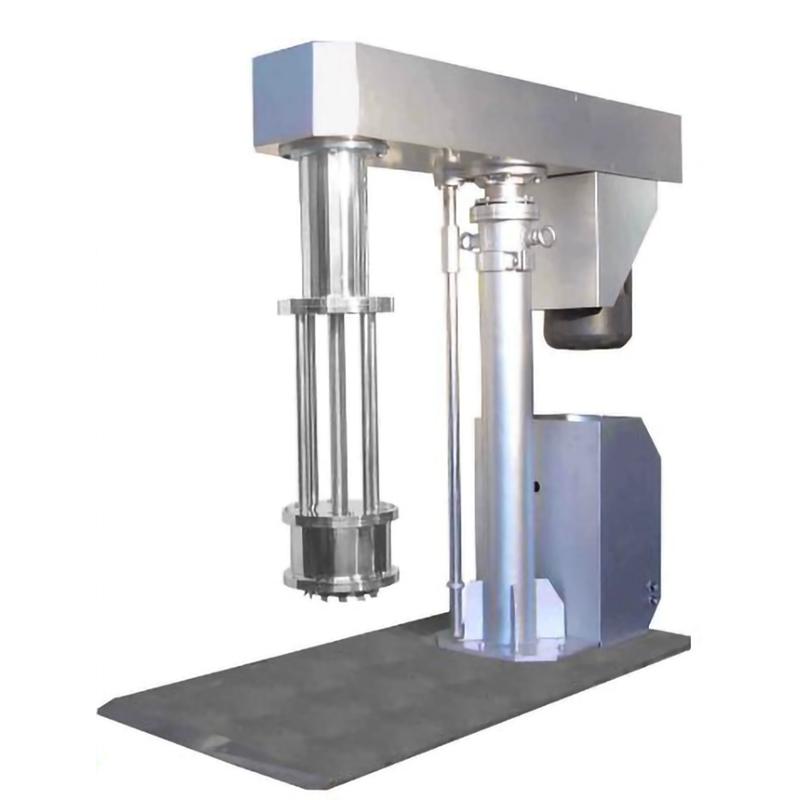

MUXUAN MXY-4 Hydraulic Lifting Grinder grinding capacity 30~100L

MuXuan MXY-4 (Hydraulic) Basket GrinderSPEC

MuXuan MXY-4 (Hydraulic) Basket GrinderDetails

MuXuan MXY-4 (Hydraulic) Basket GrinderPacking list

- SKU

- NB035014

- Motor Power

- 4kw

- Speed regulation range

- 0~1500rpm

- Lifting stroke

- 700mm

- Lifting method

- hydraulic lift

- Grinding medium

- 1.2-2 pure zirconia

- Grinding Capacity

- 30-100L

Introduction to the device

The hydraulic lifting basket mill integrates dispersion and grinding, suitable for wet grinding of medium and low viscosity fluids, belongs to the intermittent industrial production equipment, the grinding basket structure design is reasonable, and the equipment is convenient for cleaning and changing color and variety; the lifting structure adopts the hydraulic cylinder as the actuator, the lifting is stable, the integrated oil tank is selected, and the environmental protection is free of leakage; the machine is a satisfactory grinding equipment for multi-variety and multi-color products.

Scope of application

【Material viscosity】:≤5000cps(mPas)

[Applicable materials]: materials with high fineness requirements, such as interior wall latex paint, industrial paint, wood paint, various color pastes, water-based oil-based inks, pesticide suspensions, etc.

Operating Principle

The motor of the basket mill drives the lever and the bottom dispersion disc to rotate at high speed, so that the upper part of the dispersion disc and the inside of the basket cavity form a vacuum, and the slurry is sucked into the basket grinding cavity. The grinding medium in the paddle drive cavity produces force in all directions, and the particles in the material are constantly collided and rubbed by the medium, and the particle size becomes smaller and the particle size range narrows;

Advantages

1. High grinding efficiency and good product fineness

The powerful kinetic energy drives the zirconia lever to cause irregular movement of the grinding medium in the cavity, and collide with each other at high speed.Friction makes the particle size of the powder quickly smaller, and the grinding fineness can generally reach about 5um, and some products can reach submicron or even nanometerMeter level.

2. Easy to operate

The equipment uses the oil cylinder as the lifting actuator, and the grinding device is controlled to rise, stop and descend through the oil pump, which is simple and stable to operate, and has different forms of clamping device, which can quickly fix the grinding barrel and prevent the displacement of the barrel from causing accidents during work.

3. The temperature rise is small and the product is stable

The ingredient barrel is equipped with a double-layer cooling jacket, which is cooled by water during the operation of the equipment, which has a good cooling effect and a small conventional temperature riseAt 10º, the grinding chamber can be customized with cooling.

4. Strong non-standard

Non-standard explosion-proof type can be customized, the grinding chamber can be customized with zirconia material, the vacuum type equipment can be customized, and the equipment material can be customizedSS316L stainless steel.

Hydraulic upgrade basket grinding parameter table

| Model | Power kw | RPM | Lifting | Lifting stroke mm | Grinding medium | Grinding amount L |

| MXY-4 | 4 | 0-1500 | hydraulic pressure | 700 | 1.2-2.0 pure zirconia | 30-100 |

| MXY-7.5 | 7.5 | 0-1500 | hydraulic pressure | 700 | 1.2-2.0 pure zirconia | 40-200 |

| MXY-11 | 11 | 0-1300 | hydraulic pressure | 900 | 1.2-2.0 pure zirconia | 50-300 |

| MXY-15 | 15 | 0-1300 | hydraulic pressure | 900 | 1.2-2.0 pure zirconia | 50-400 |

| MXY-18.5 | 18.5 | 0-1300 | hydraulic pressure | 900 | 1.2-2.0 pure zirconia | 80-600 |

| MXY-22 | 22 | 0-1100 | hydraulic pressure | 1200 | 1.2-2.0 pure zirconia | 150-800 |

| MXY-30 | 30 | 0-1100 | hydraulic pressure | 1200 | 1.2-2.0 pure zirconia | 250-1200 |

| MXY-37 | 37 | 0-1100 | hydraulic pressure | 1200 | 1.2-1.4 Pure zirconia | 500-1500 |

| MXY-45 | 45 | 0-1000 | hydraulic pressure | 1400 | 1.2-1.4 Pure zirconia | 500-2000 |

| MXY-75 | 75 | 0-900 | hydraulic pressure | 1500 | 1.2-1.4 Pure zirconia | 600-3000 |

◆ The material contact part material can be customized according to the material characteristics of 304/316/Hastelloy/titanium-molybdenum-nickel alloy and other materials.

MXY-4 (Hydraulic)

MXY-4 (Hydraulic)