MUXUAN S65-3 Lab Three-roll Grinder High Viscosity Material Dispersion Grinder

SEMuXuan S65-3 Three-roll GrinderSPEC

MuXuan S65-3 Three-roll GrinderDetails

MuXuan S65-3 Three-roll GrinderPacking list

- SKU

- NB035048

- Power

- 0.75KW

- Roller working length

- 128mm

- Roller diameter

- 65mm

- Rotation speed

- 23rpm

- Voltage

- 220/380/110V

- Dimensions

- 450*400*430mm

- Weight

- 98 kg

- Rotation speed

- 178rpm

- Rotation speed of middle roller

- 66rpm

Equipment introduction

The S65 laboratory three-roller Grinder is suitable for use with pastes or high-viscosity materials that need to be dispersed and have high fineness requirements. By squeezing each other on the surfaces of three horizontal rollers, the distance between the rollers can be adjusted by hand. The grinding effect is achieved by friction at different speeds. Equipped with an emergency stop button to prevent equipment damage caused by falling foreign objects. The rollers are cast from special carbide or pure zirconia.

Application scope

ãMaterial viscosityã: â¤3,000,000cps

ãProduction capacityã: 0.5-10kg/h

[Application fields]: Materials with a material viscosity below 3,000,000 cps, high grinding fineness requirements, and high product viscosity; such as offset printing ink, chocolate, lithium battery slurry, electronic glue, silver-aluminum slurry, and more than a thousand kinds of materials.

[Applicable materials]: It is suitable for dispersing and grinding product materials in industries such as ink, color paste, adhesive, biology, medicine, food, cosmetics, coatings, and photovoltaic materials.

Features

Wide range of applications

When designing the equipment, the center projection of the roller can be adjusted according to the viscosity of the material, and it can be used for products with high, medium and low viscosity.

Stable product with small temperature rise

Cooling water can flow through the rollers when the equipment is running, which has a good cooling effect and ensures product quality.

Strong non-standard

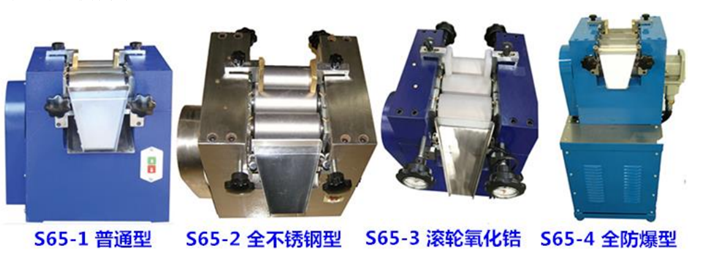

Non-standard explosion-proof types can be customized; roller materials can be customized with ceramic materials such as zirconia and alumina.

Principle

The laboratory three-roller Grinder consists of three rollers, mounted on a frame and driven directly by an electric motor. Generally, the rotation directions of the rollers are different. The front roller rotates forward and the middle roller rotates backward. The roller speed is faster for the front roller and slower for the rear roller. The middle roller is fixed, and the front and rear rollers are installed on the slide track. There are spring devices. The distance between the front and rear rollers and the middle roller can be adjusted with the hand wheel. The material enters between the rear roller and the middle roller, is squeezed by the roller, and the product particles become finer, and then is brought out by the fast roller. The end of the fast roller is equipped with a scraper to separate the material from the roller and fall into the collection bucket.

S65-3

S65-3