HUXI HR-500D Digital Display High Shear Dispersion Mulser

HuXi HR-500D Digital Display High Shear Dispersion MulserSPEC

HuXi HR-500D Digital Display High Shear Dispersion MulserDetails

HuXi HR-500D Digital Display High Shear Dispersion MulserPacking list

- SKU

- NB035544

- Power

- 500W

- Power supply Voltage

- 220V 50/60HZ

- Speed range

- 10000~28000rpm

- Rotation speed display

- digital display

- Speed regulation mode

- stepless speed regulation

- Processing Capacity

- 0.2~7000mL

- Standard working head

- 25G

- Contact material

- SS316L

- Immersion Material Sleeve Material

- PTFE

- Rotation speed deviation

- 1%

Applications

Originated from Germany, it combines dexterity and convenience. It can be operated by hand, and the German motor is selected, which makes the operation more stable and the noise is smaller. The speed can reach 28000rpm, it can run for a long time, and more than 20 kinds of working heads can be selected, which can realize vacuum operation and easily meet a variety of high-demand dispersion, emulsification, and homogenization experimental requirements. The high-speed homogenization emulsifier is composed of a high-speed rotating rotor and a precise stator working cavity, relying on high linear speed to produce strong hydraulic shearing, centrifugal extrusion, high-speed cutting and collision, so that the material is fully dispersed, emulsified, homogenized, crushed and mixed, and finally a stable high-quality product is obtained.

HR500-D type is often used in biochemical, food, nanomaterials, coatings, adhesives, daily chemicals, printing and dyeing, petrochemical, paper chemistry, polyurethane, inorganic salts, asphalt, silicones, pesticides, water treatment, heavy oil emulsification and other industries.

Features

1. The original German motor is selected, the operation is stable, the noise is smaller, it can run for a long time, and the design is safe and reliable;

2. The parts of the working head in contact with the material are all made of good stainless steel, with good corrosion resistance;

3. The working head is connected with the drive motor by coupling, which is easy and flexible to disassemble and assemble;

4. The speed regulating base adopts stepless speed regulator, which is convenient for speed regulation and stable operation.

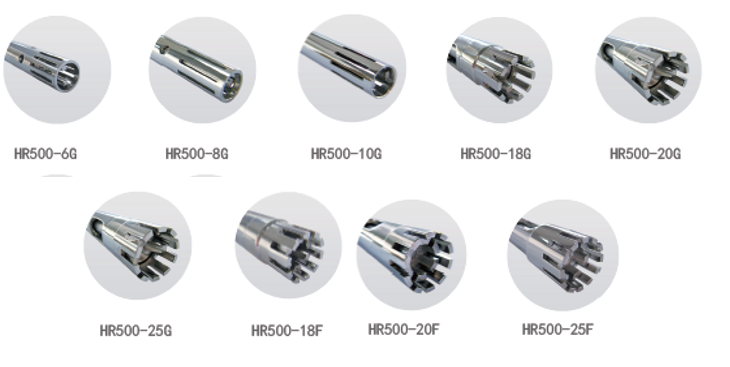

Optional cutter heads

| specification | Throughput (ml) | viscosity | Material |

| 6G | 0.2-10 | 100 | SS316L |

| 8G | 1-60 | 100 | SS316L |

| 10G | 10-150 | 200 | SS316L |

| 18G | 50-1500 | 3000 | SS316L、PTEE |

| 20G | 50-1500 | 3000 | SS316L |

| 25G | 100-5000 | 5000 | SS316L、PTEE |

| 18G | 50-1500 | 2000 | SS316L |

| 20F | 50-1500 | 3000 | SS316L、PTEE |

| 25F | 100-1500 | 3500 | SS316L、PTEE |

HR-500D

HR-500D