Film coater PES film coated graphene dispersion 12μm Spreader

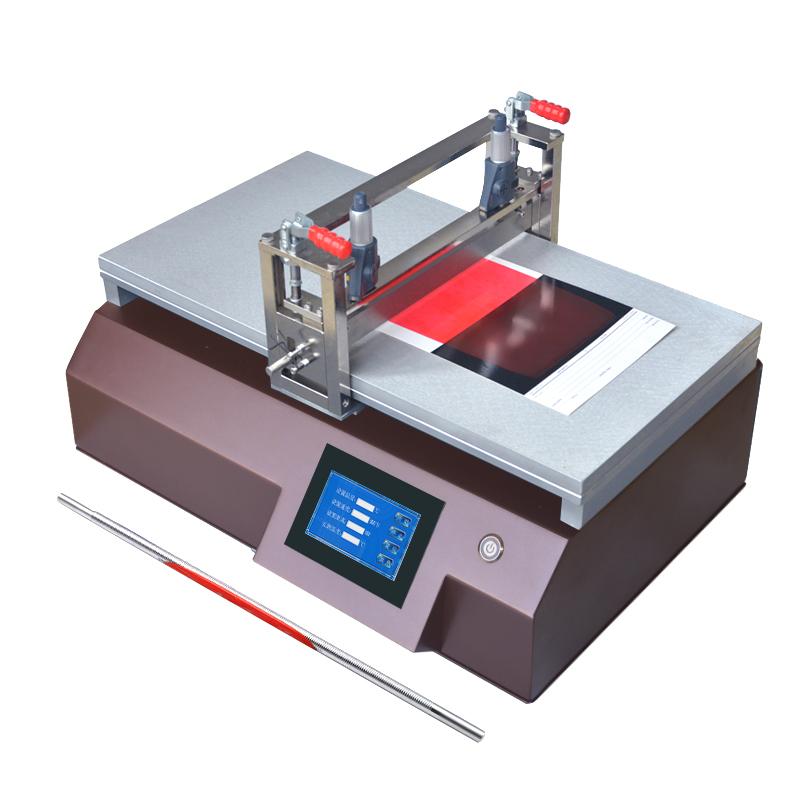

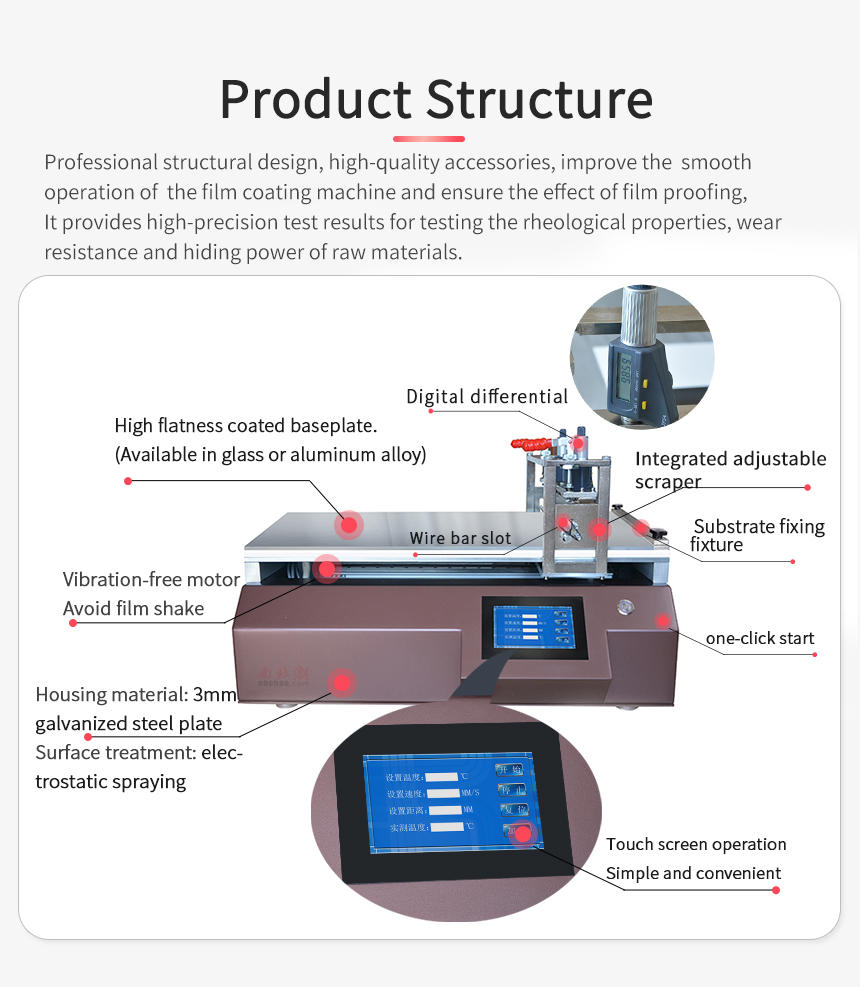

zy TBJ-X3+OSP-12/400 Automatic Film ApplicatorSPEC

zy TBJ-X3+OSP-12/400 Automatic Film ApplicatorDetails

zy TBJ-X3+OSP-12/400 Automatic Film ApplicatorPacking list

- SKU

- NB035661

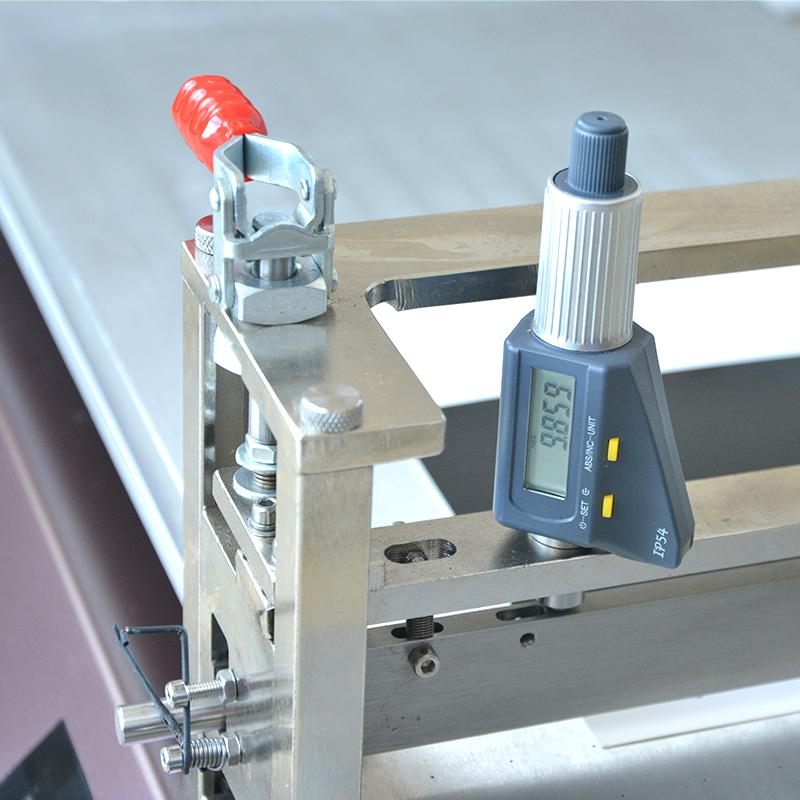

- Drawdown blade Accuracy

- ±0.003mm

- Spreader thickness range

- 0~10Mm drawdown blade can be lifted

- Coating speed

- 5~ 180Mm/s (< 5mm/s can be customized)

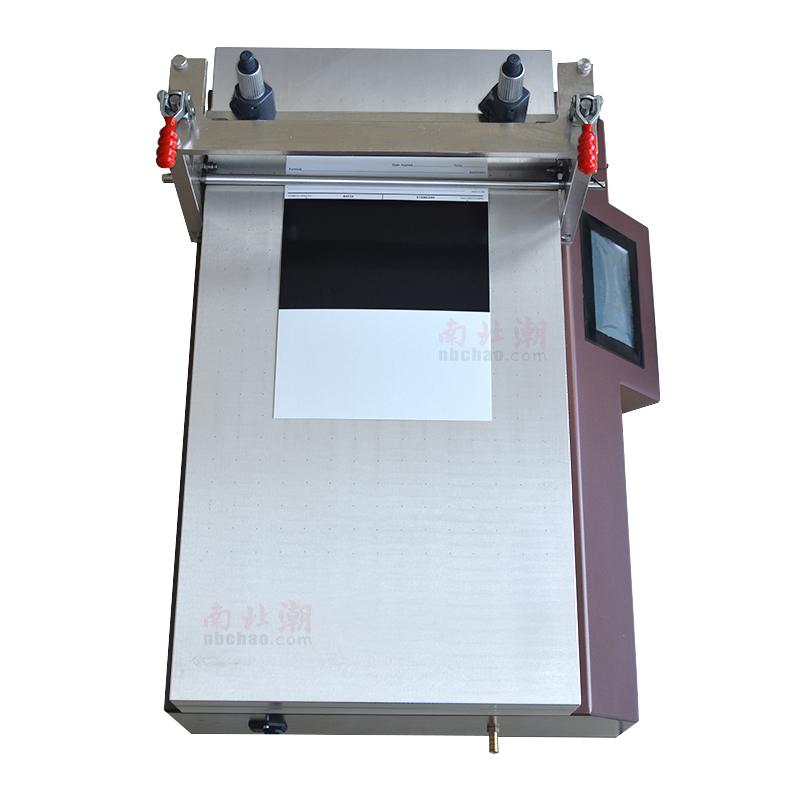

- Coating size

- 300*400mm

- Spreader speed

- Digital display, different speeds

- Vacuum Area

- 300 * 400Mm (can be customized)

- Vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Drawdown blade

- length

- Coating rod specification

- 1 imported 12μm wire rod + 1 China wire rod

- Host Power

- 220V 50Hz

- Dimensions

- 630*410*520mm

- Weight

- Net Weight 65KG

- speed control

- Infinitely variable speed

- Bottom plate material

- aluminum alloy

- Heating temperature range

- RT+~200℃

- Temperature Uniformity

- ±3℃

- Power

- 1500W

- Vacuum pump size

- 380*180*280mm

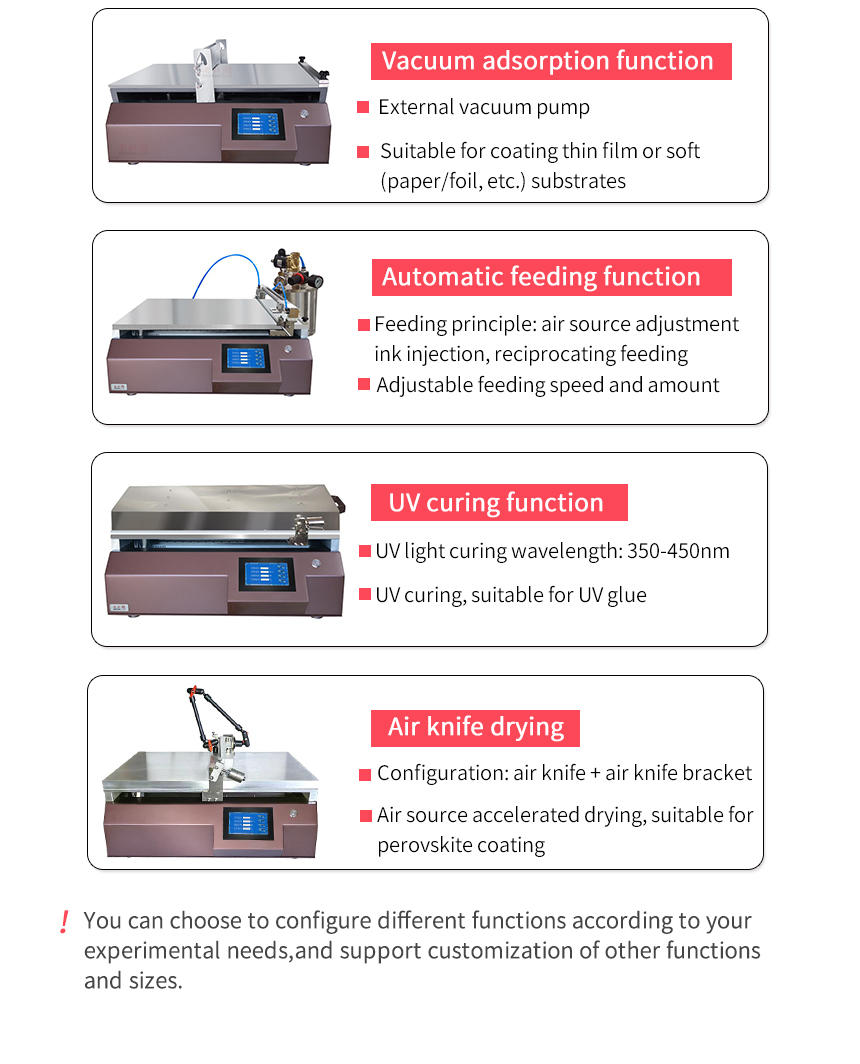

- Customizable function

- Jet system device, UV solid-containing device, automatic inking system

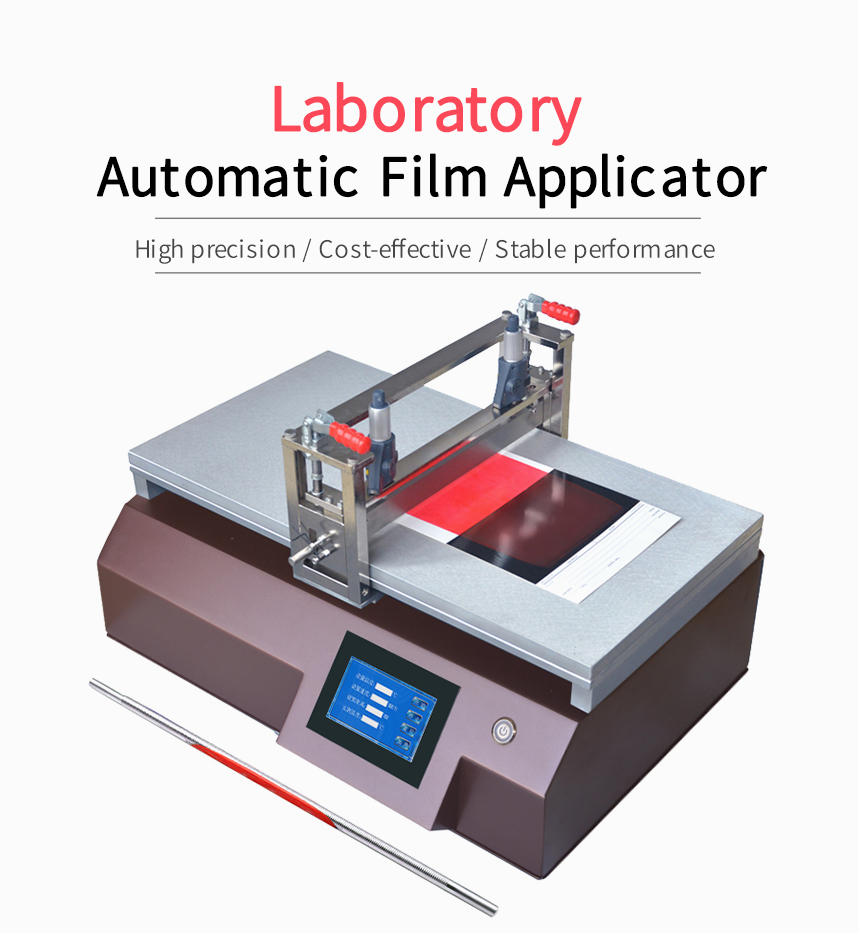

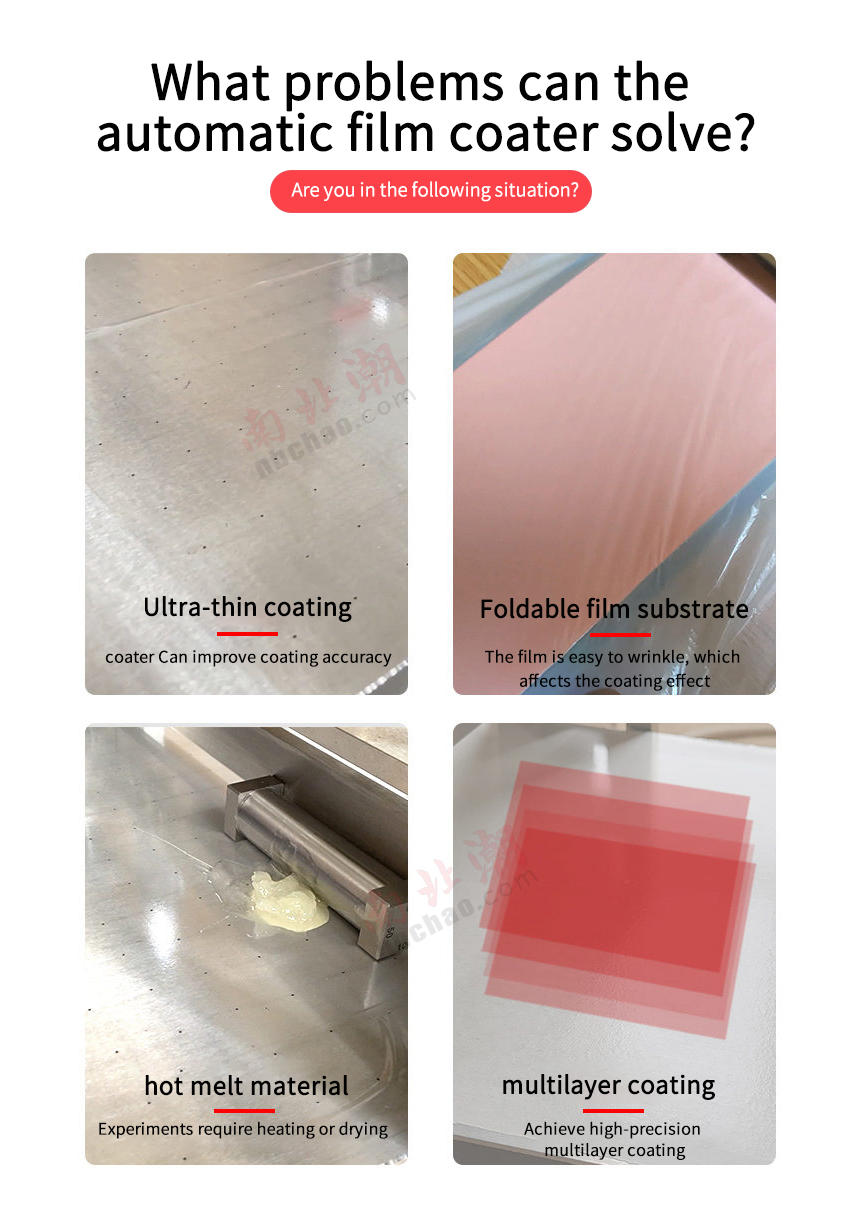

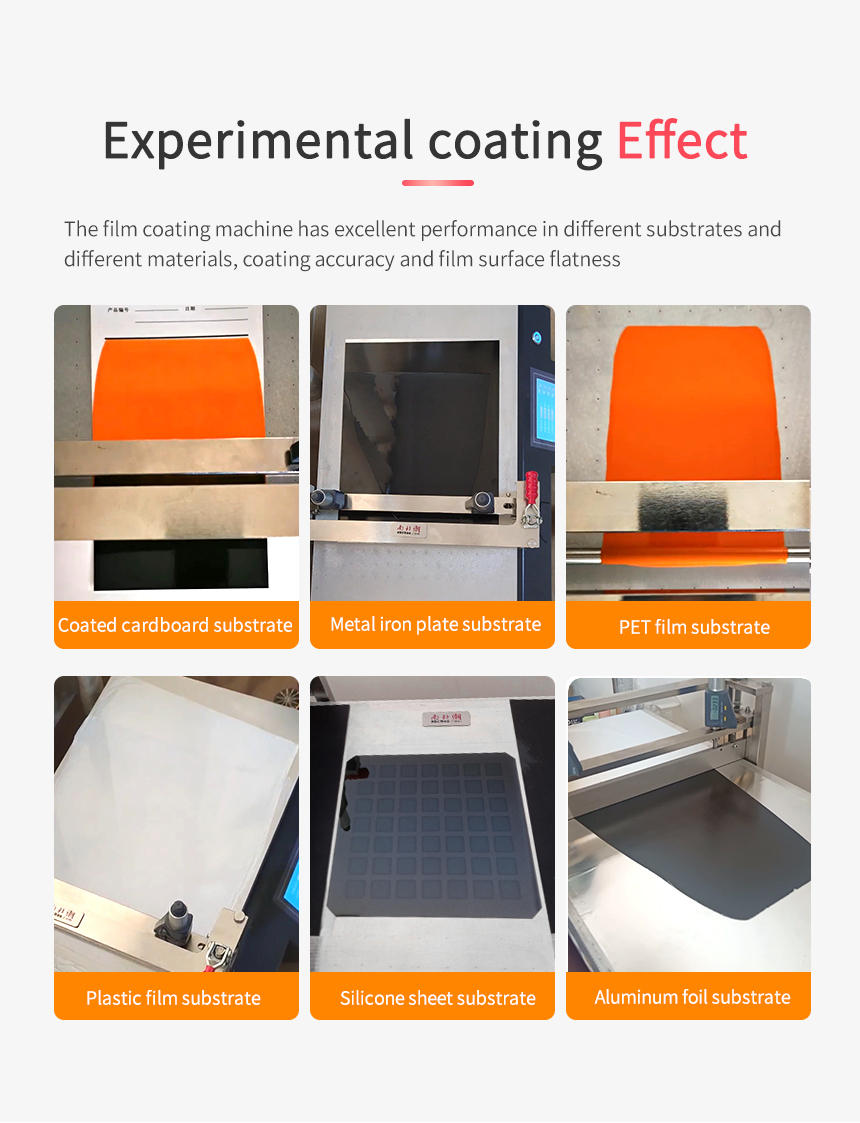

product description

This laboratory coater set is a coating instrument and equipment used to blade-coat graphene dispersion on PES film. The coating thickness is 12 μm. The PES film substrate is a soft substrate and requires vacuum adsorption to keep it flat. Graphene requires heating at a certain temperature to maintain its molten state.

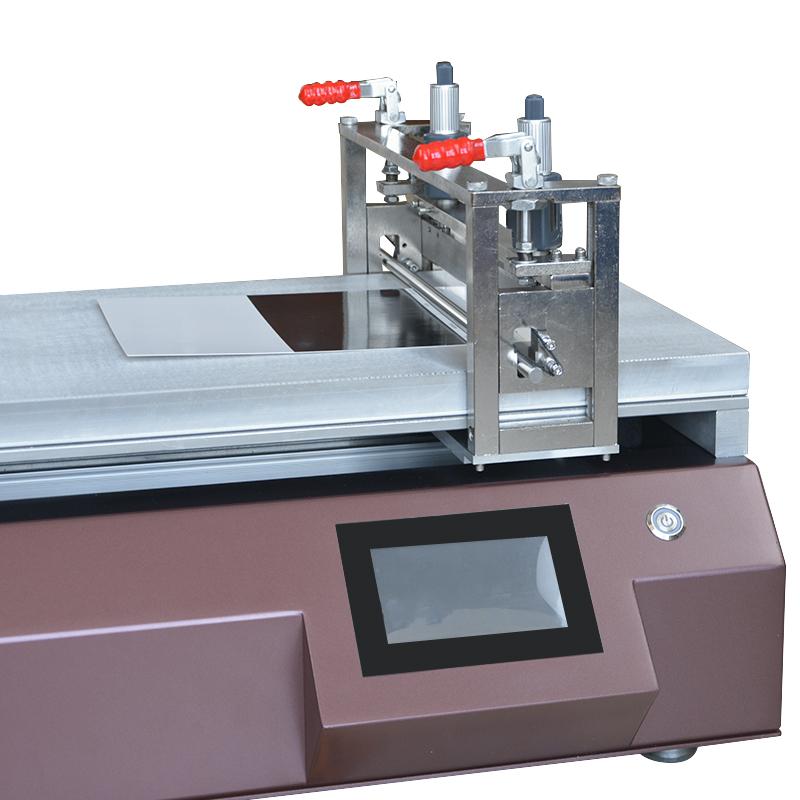

The TBJ-X3 experimental film coating machine is a four-in-one coating machine with vacuum adsorption and heating functions. It is also equipped with an imported OSP No. 12 rod and a domestic (CN) wire rod, with a heating temperature of 200℃. Using imported accessories, the coating accuracy can reach 1μm.

This film coating machine comes standard with imported OSP wire rods, which are used for scraping and coating 12μm thick graphene wet films.

Features

The film coating machine comes standard with imported high-precision wire rods

With 200℃ heating function

With vacuum adsorption function

By controlling the speed and stable pressure, the coating effect is ensured, and the uniformity and stability of the coating are ensured.

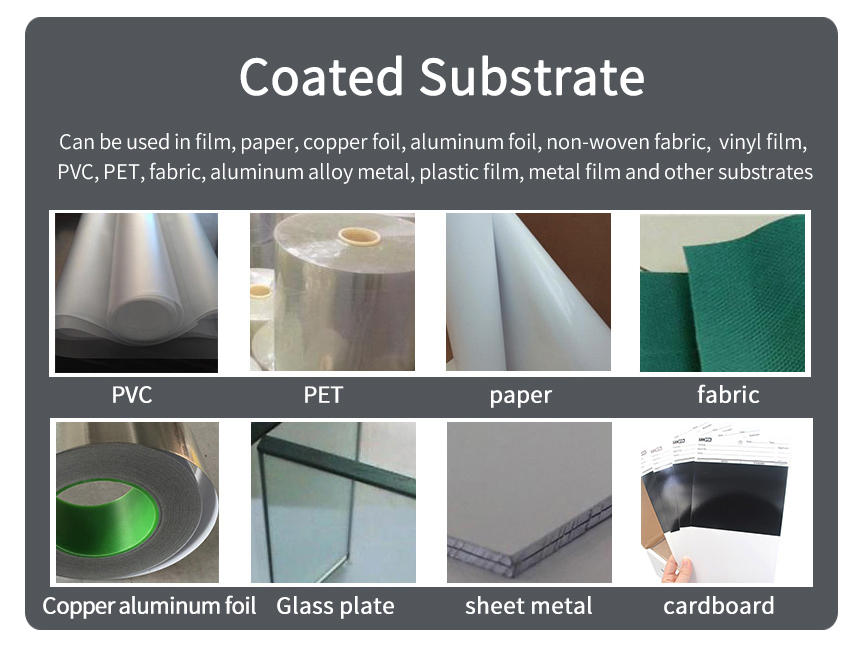

Coating experiments can be carried out on various flat materials such as paper, plastic, metal, PVC, PET, cloth, and aluminum alloy plates.

Why do we need imported wire rods?

The experimental coating effect is the result of the joint action of the coating machine and the wire rod. The automatic coating machine can control the speed and pressure of coating, while the wire rod coater/preparator determines the accuracy of the coating film. The coating accuracy of the imported wire rod can be as high as 0.1μm, and the matching imported wire rod can achieve ultra-thin and high-definition coating. Precision coating.

Coating machine type selection table

| Optional configuration functions of coating machine | Main application options |

| Wire rod type | Ultra-thin/high-precision coating, requiring multiple coatings (accuracy up to 0.1μm) |

| scraper type | High viscosity samples, large film thickness, and large particle fineness |

| Heating type | Lithium batteries/glue and other samples that need to be coated at a certain temperature (temperature up to 200℃) |

| Vacuum adsorption | Film, paper and other substrates that are not easy to flatten |

| Note: The fabric is breathable, so there is no need to choose the vacuum type. For paper that is difficult to flatten, you need to choose the vacuum adsorption type. | |

*All configuration functions can be freely combined and selected, such as wire rod type, wire rod + scraper, wire rod + heating, scraper + heating, wire rod + scraper + heating + vacuum adsorption, scraper + vacuum adsorption, etc. The specifications are not suitable. NBCHAO supports customization.

The coating thickness specification selection of imported wire rods is as follows:

For more coating thickness requirements, please consult the mall customer service.

TBJ-X3+OSP-12/400

TBJ-X3+OSP-12/400