TENLIN DC-8010 Vertical ultra-low temperature Thermostatic Bath - 80 ℃/ +/- 0.05 ℃ 10L

SETenLin DC-8010 Thermostatic BathSPEC

TenLin DC-8010 Thermostatic BathDetails

TenLin DC-8010 Thermostatic BathPacking list

- SKU

- NB035961

- Temperature range

- -80~100℃

- temperature resolution

- 0.01℃

- Temperature fluctuation

- ±0.05℃

- Dimensions

- 660*660*1350mm

- power

- 3.6kw

- Tank Volume

- 10L

- Tank opening Dimensions

- 180*160mm

- groove depth

- 200mm

- Circular mode

- Domestic circulation

Features

● New self-developed temperature control technology, equipped with high-standard PT100 and all imported electronic components.

● The software system can correct the error between the displayed temperature and the actual temperature, so that the displayed temperature value is accurate.

● Equipped with large-screen liquid crystal display as standard, multiple data can be seen at a glance, and the resolution of temperature display is up to 0.01℃.

● With over-temperature protection, over-temperature beep alarm, over-temperature alarm temperature can be set, and the load can be automatically cut off when over-temperature.

● With timing function, the total working time of the equipment can be set, and the load will be cut off automatically when the time comes.

● Hidden cooling coil design ensures a larger space in the tank.

● Intelligent software has strong temperature stability, PID can automatically adjust the appropriate parameters according to different media, and special users can manually readjust the parameters.

● Use the software to digitally lock the setting values of the control system to avoid misoperation by irrelevant personnel and ensure that the data during the experiment is correct.

● Effective full-enclosed compressor refrigeration, fast cooling speed, with multiple protections such as overheating and overcurrent.

● The internal and external circulation function is equipped as standard, and the outer diameter of the external circulation inlet and outlet is a round pipe with an outer diameter of 10mm, which meets the different needs of users in multiple scenarios.

● Support non-standard customization.

Optional

Liquid level protection system --- When the liquid level exceeds the limit, the load will be stopped forcibly to protect the user's experiment.

RS485 communication interface--connect to a host computer such as a computer, and the host computer software controls the device and checks the data.

Multi-point correction function-can correct multiple temperature points at the same time, avoiding the temperature difference caused by the linear error of the sensor.

External PT100 - can realize the precise temperature control of the external circulation.

Bracket--Satisfied that different containers are placed in the tank to avoid being submerged in constant temperature liquid.

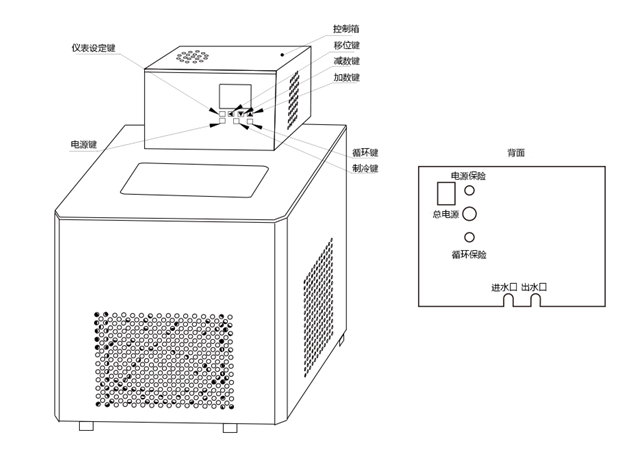

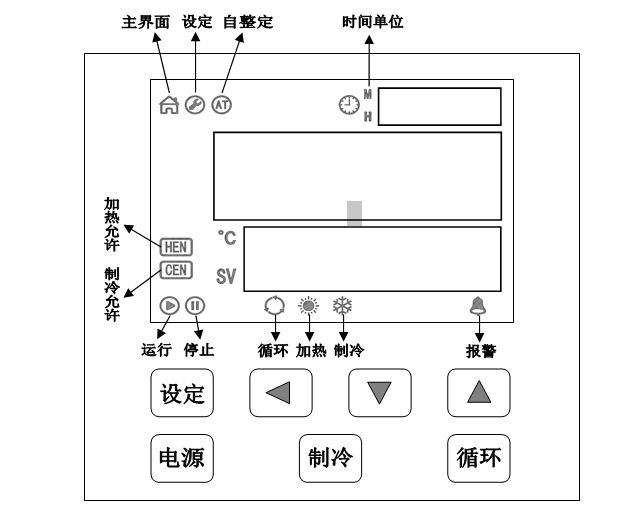

external structure

Figure 1: Outline structure of DC constant temperature bath

Figure 2: DC thermostatic bath control panel

Model parameters

| model | temperature range | power | tank volume |

| DC6006 | -60-100 | 3.2 | 7.5 |

| DC7006 | -70-100 | 3.3 | 7.5 |

| DC8006 | -80-100 | 3.5 | 7.5 |

| DC6010 | -60-100 | 3.4 | 10 |

| DC7010 | -70-100 | 3.5 | 10 |

| DC8010 | -80-100 | 3.6 | 10 |

| DC6015 | -60-100 | 3.5 | 15 |

| DC7015 | -70-100 | 3.6 | 15 |

| DC8015 | -80-100 | 3.7 | 15 |

| DC6020 | -60-100 | 3.7 | 20 |

| DC7020 | -70-100 | 3.8 | 20 |

| DC8020 | -80-100 | 3.9 | 20 |

| DC6030 | -60-100 | 4 | 30 |

| DC7030 | -70-100 | 4.2 | 30 |

| DC8030 | -80-100 | 4.5 | 30 |

| resolution | 0.01°C | ||

| Volatility | ±0.05℃ | ||

| pump flow | Inner loop | ||

| Unit ℃/Kw/L | |||

- 1JJF 2019-2022《Measurement Specification for Temperature Performance of Liquid Constant Temperature Testing Equipment》

- 2JJF 1030-2023《Measurement and Test Norm of Metrological Characteristics of Thermostatic Baths for Temperature Calibration》

- 3GB/T 26809-2011《Thermostatic baths and circulators - Refrigerated circulators》

- 4GB/T 32710.3-2016《Safety requirements for environmental testing and conditioning equipment—Part 3: Refrigerated baths》

- 5JJF 1030-2010《Measurement and Test Norm of Thermostatic Bath's Metrological Characteristics》

- 6GB/T 26808-2011《Thermostatic baths and circulators - Refrigerated baths》

- 7JB/T 5376-1991《Thermostatic bath conditions》

- 8GB/T 11175-2002《Testing methods for synthetic resin emulsions》

DC-8010

DC-8010