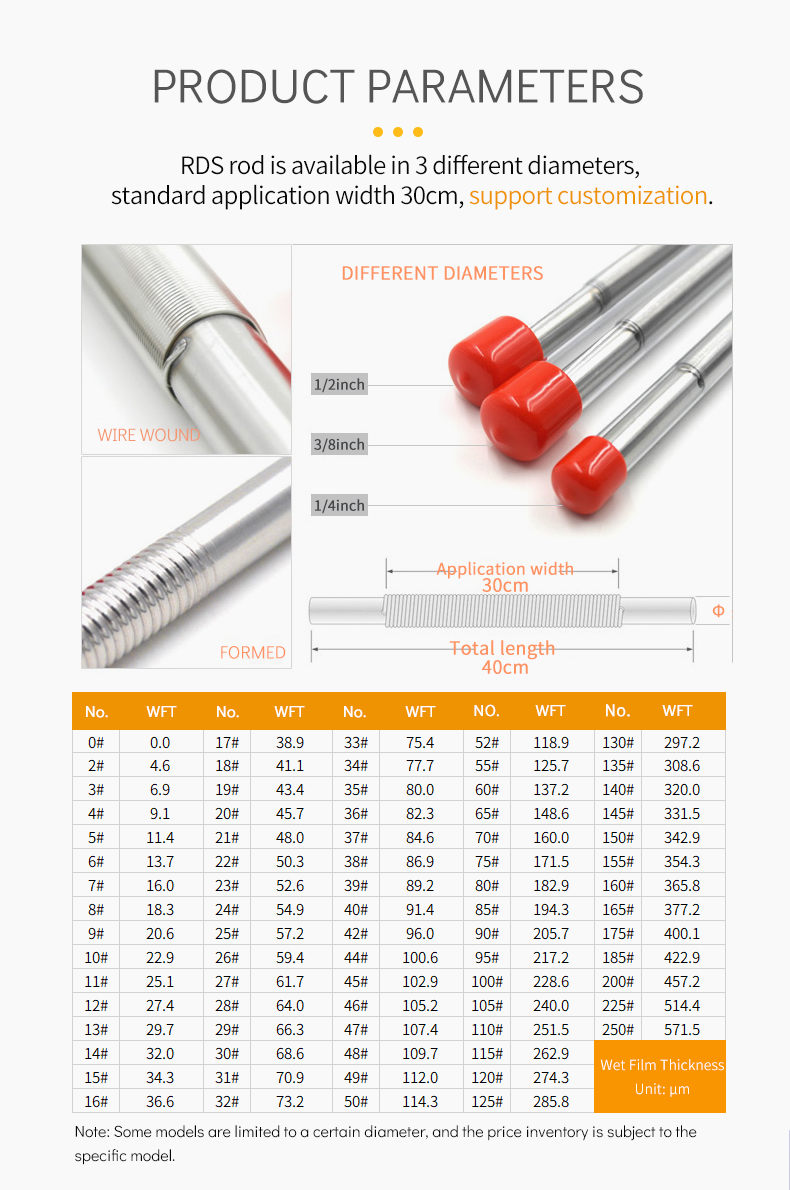

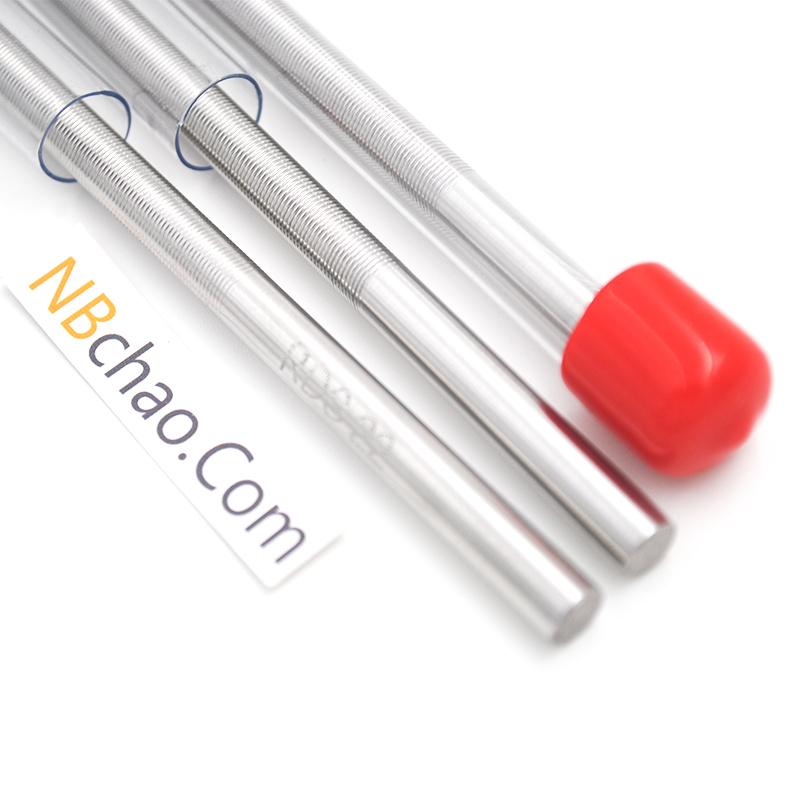

RDS #45 Mayer Rods WFT 102.9μm length 400mm

SEExtrusion process, 102.9μm, 1/4 inch diameter, stainless steel Applicator rod Total length 40cm, can be prepared 30cm film.

$156.00/piece

PromotionLoading...

Coupon

Model:

Similar products

RDS 45# 1/4“ Applicator rod 1/4 "SPEC

RDS 45# 1/4“ Applicator rod 1/4 "Details

RDS 45# 1/4“ Applicator rod 1/4 "Packing list

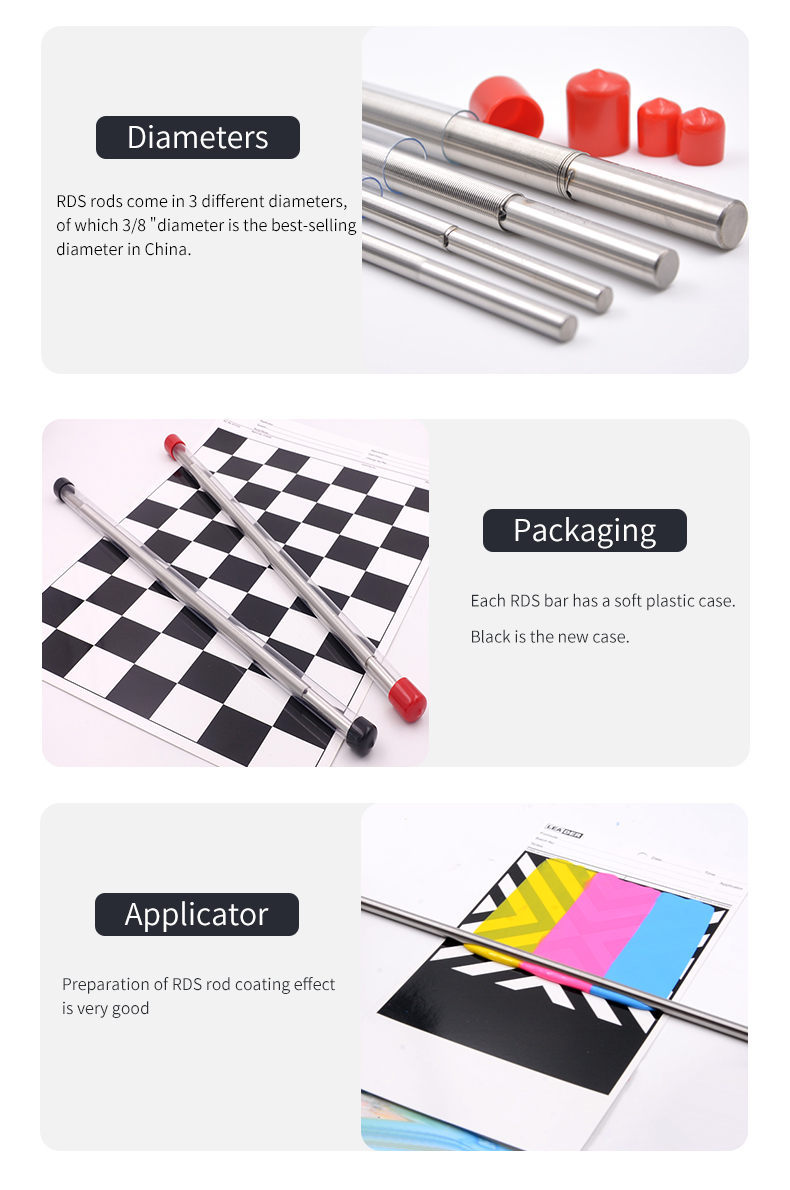

- SKU

- NB000036

- Production process

- formed

- WFT

- 102.9μm

- diameter

- 6.35mm

- Total length

- 400mm

- application width

- 300mm

- Grip Width

- 50+50mm

- material

- stainless steel

45# 1/4“

Applicator rod 1/4 "

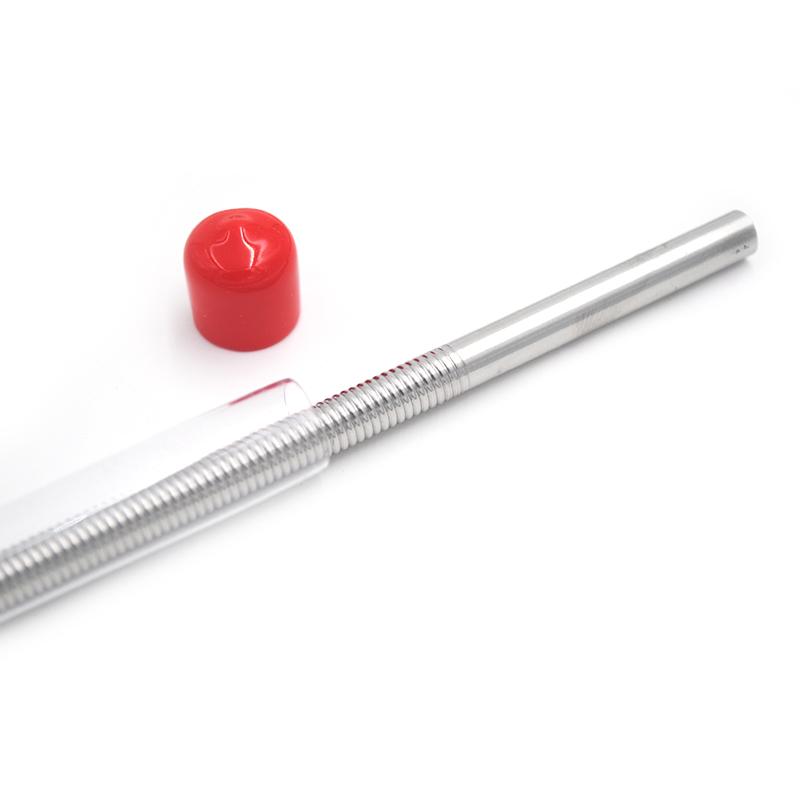

Extrusion process, 102.9μm, 1/4 inch diameter, stainless steel Applicator rod Total length 40cm, can be prepared 30cm film.

Product description

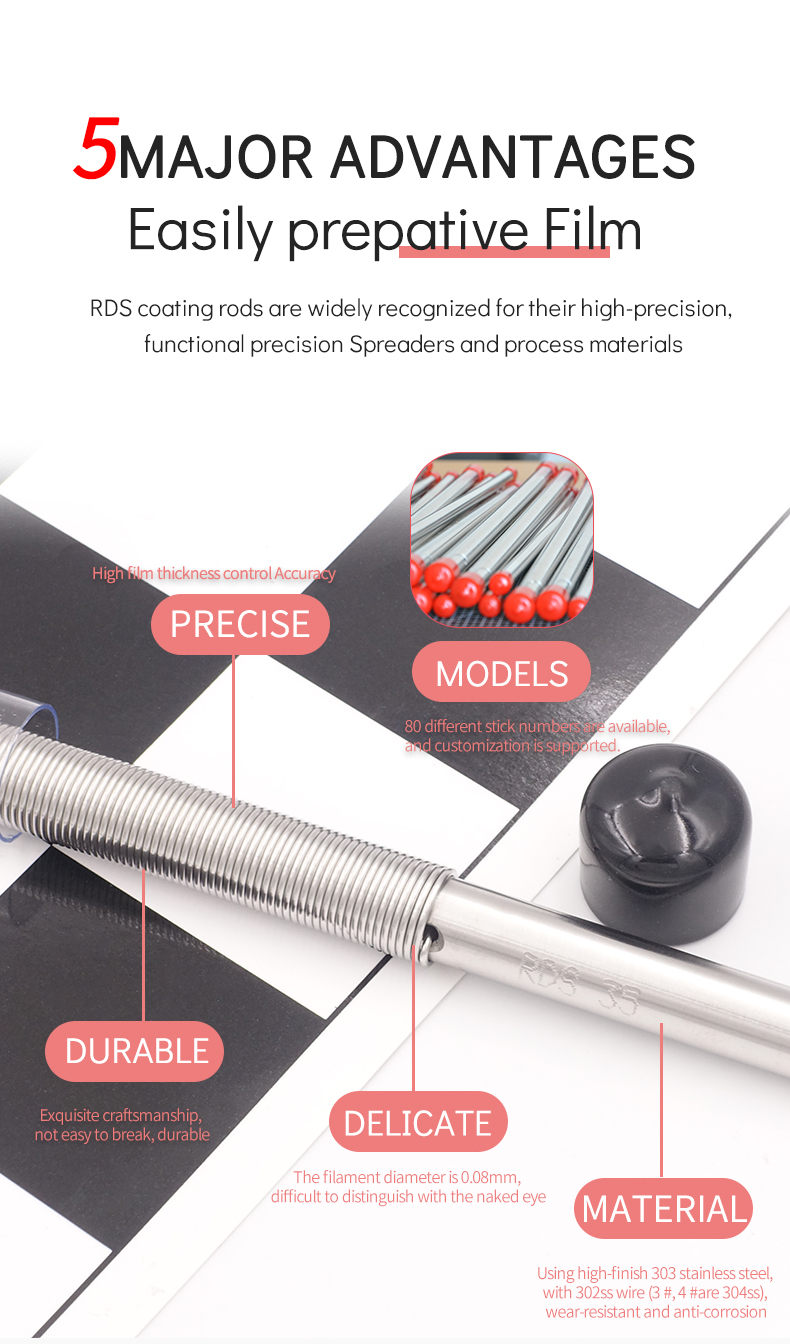

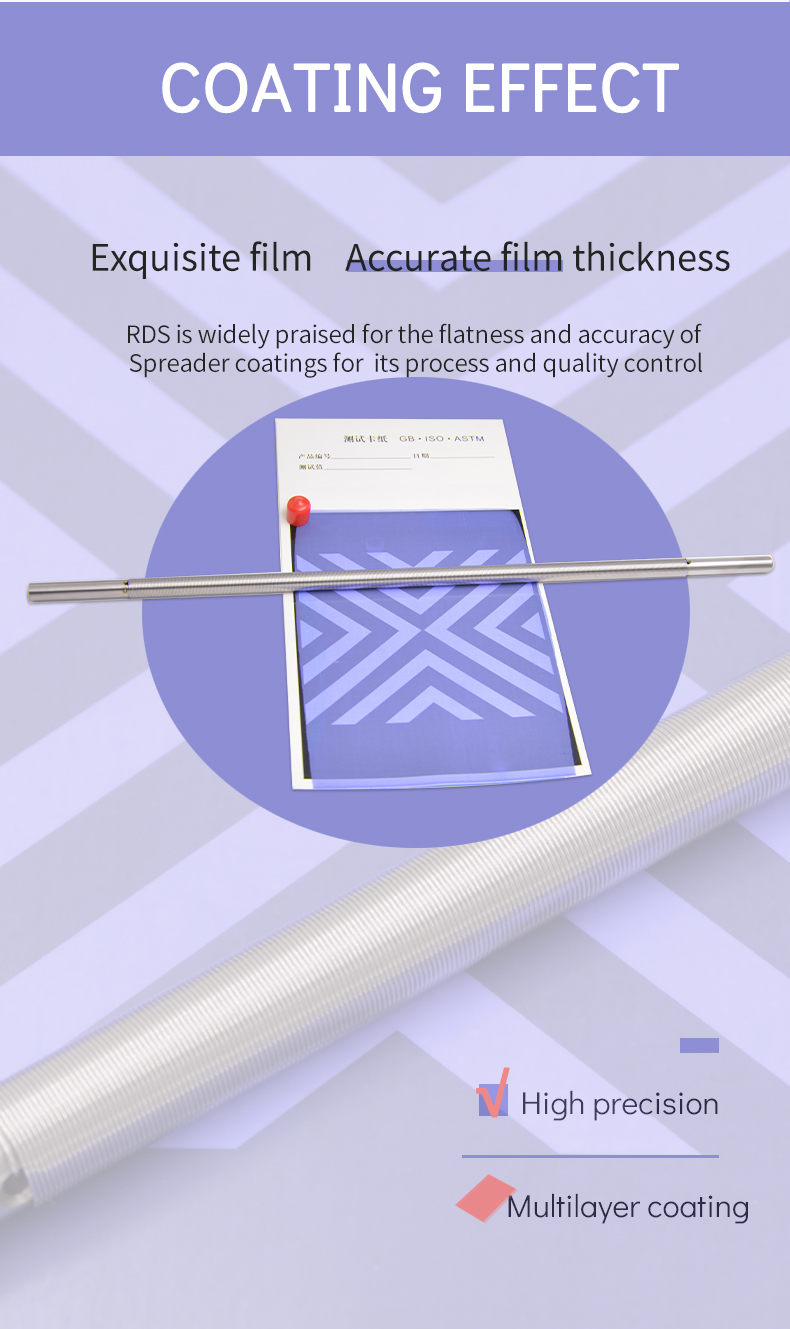

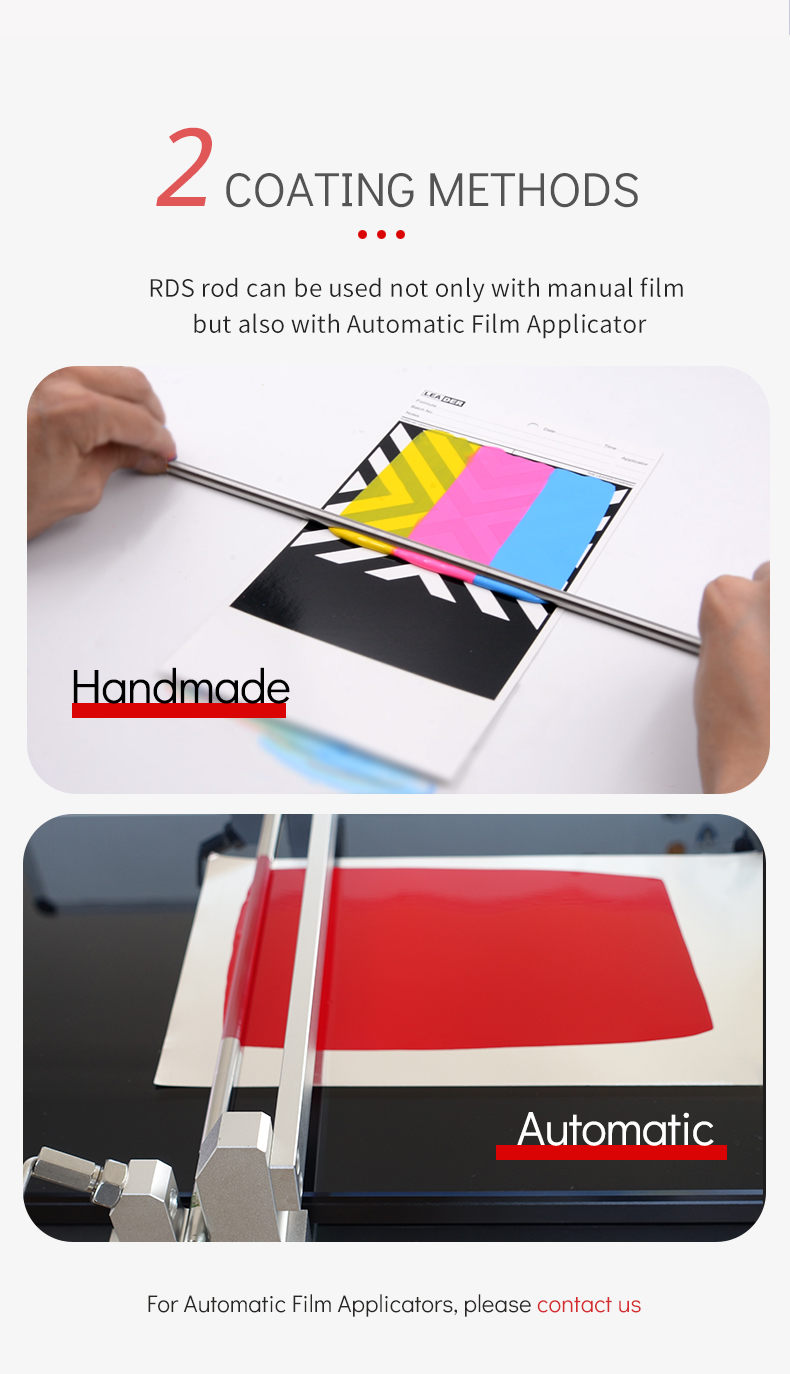

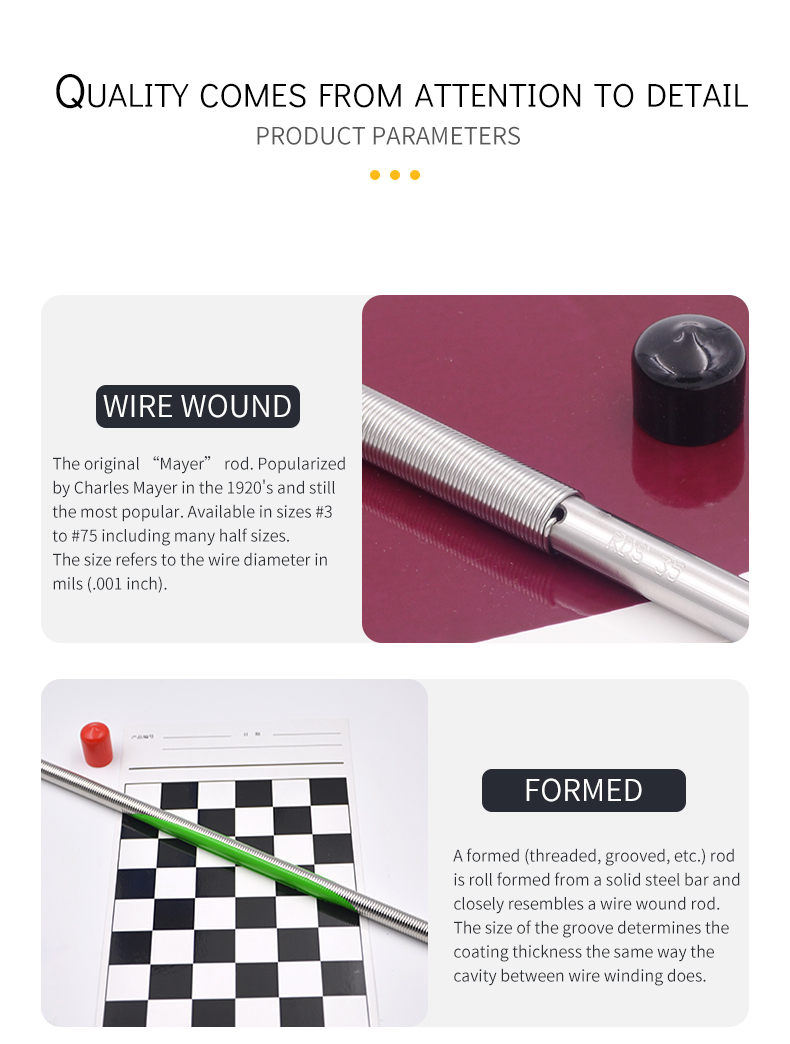

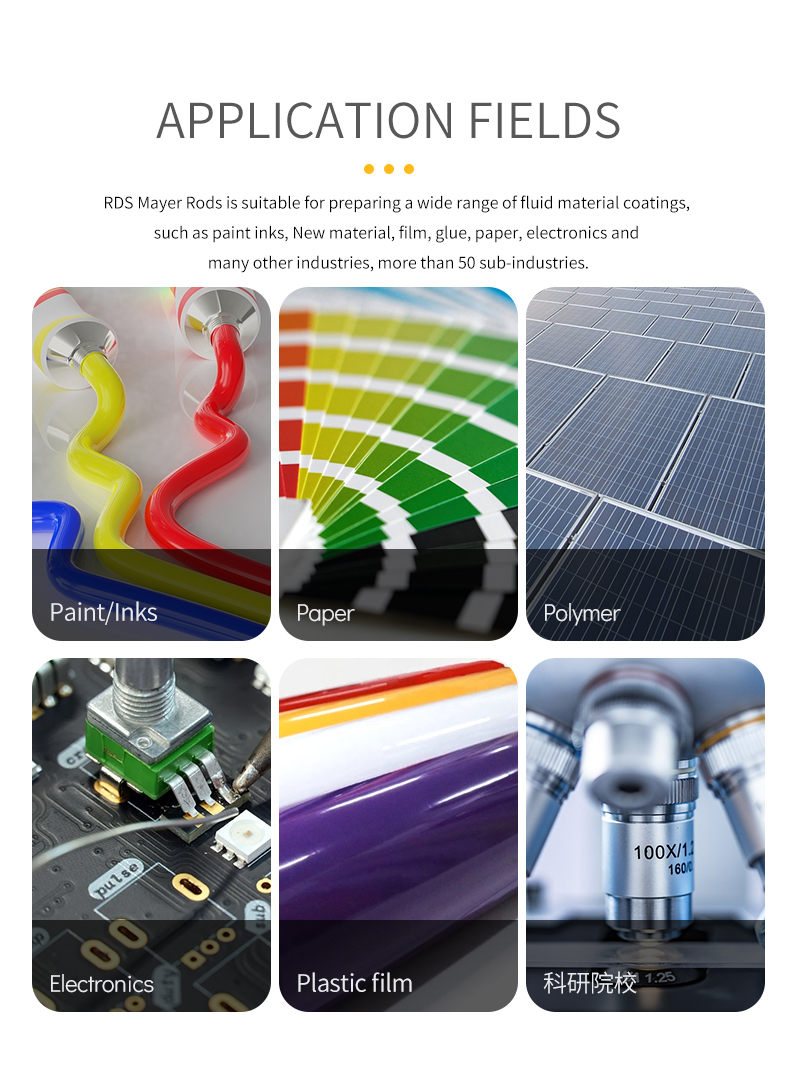

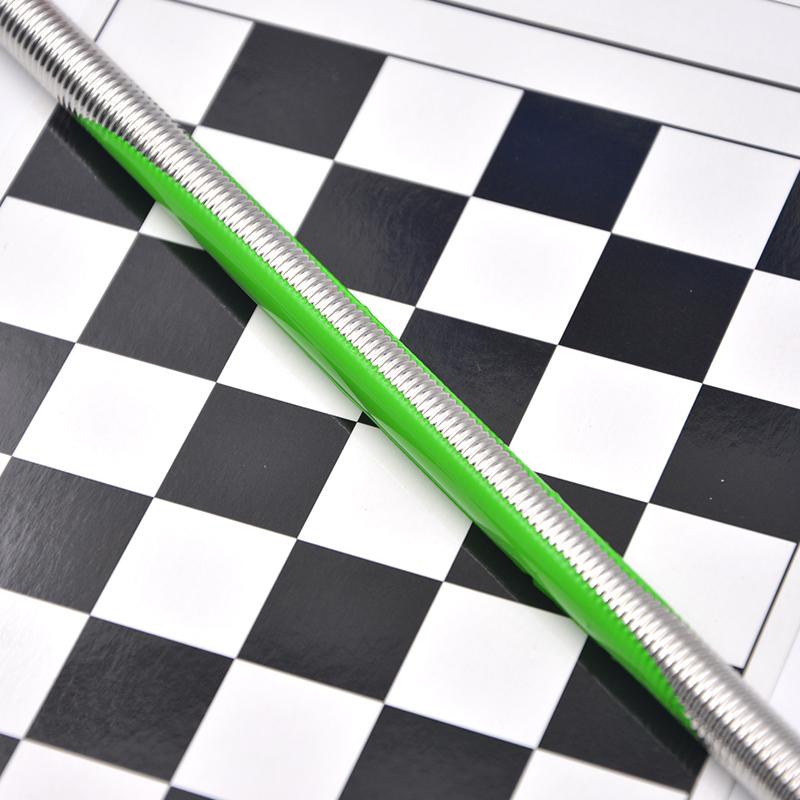

RDS#45 wire rod coater only provides the wire rod coater of forming process, the diameter is 1/4 inch, and the thickness of the coating film is 102.9 μm. The RDS forming coating rod inherits the advantages of the RDS wire wound coating rod, which is made of austenitic high-grade stainless steel and can prepare a film thickness of 0.1 μm with high precision. Through special processing technology, it is developed without winding steel wire. The extruded coating rod is formed, and the wet film thickness is determined by the size of the U-shaped groove of the coating rod. RDS Formed Coating Rods are not only easy to clean, but also suitable for occasions such as high-viscosity inks or high-abrasion experiments.

FAQ

QCan it be used to scrape Water-based ink?

A

Hello, yes, what wet film thickness do you need?

QDo you support customization? Such as wet film thickness and length?

A

Spreader rod length and main rod diameter support customization, but wet film thickness RDS has provided dozens of specifications covering more than 200 microns, and in principle does not accept customization.

QDoes the extruded wire rod meet the specifications of GB/T13217.1?

A

Model 45 #1/4 "Extrusion Wire Compliant

QSpreader and swirl/spin film, pull film what is the difference? Which is good?

A

Swirl/spin film coating can not cover the surface of the substrate Glass, Coating is thrown out of the filamentous film and uneven; pull film uniformity is good, Glass substrate on both sides, transparency is general, film thickness is not easy to control; Spreader Glass surface uniformly covered, good transparency, Coating less, and can control the film thickness well.

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- 2Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 3Application of Mayer Rods in Water-based ink Moulding

- 4Advantages of Bar Spreader in corrosion coating prepative

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 7044-2022《Colour carbon black》

- 3HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 4HG/T 5370-2018《Waterborne coatings for bicycles》

- 5HG/T 5065-2016《Finishing varnishes for architectural coatings》

- 6HG/T 3951-2007《Water based colorants for architectural coatings》

- 7HG/T 3948-2007《Hot Melt Adhesives for Sanitary napkin & Panty liner》

- 8GB/T 13217.1-2009《Test method for colour of liquid ink》

- 9ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

- 10JB/T 7663.2-2007《Technical conditions for positive displacement compressor painting》

45# 1/4“

45# 1/4“