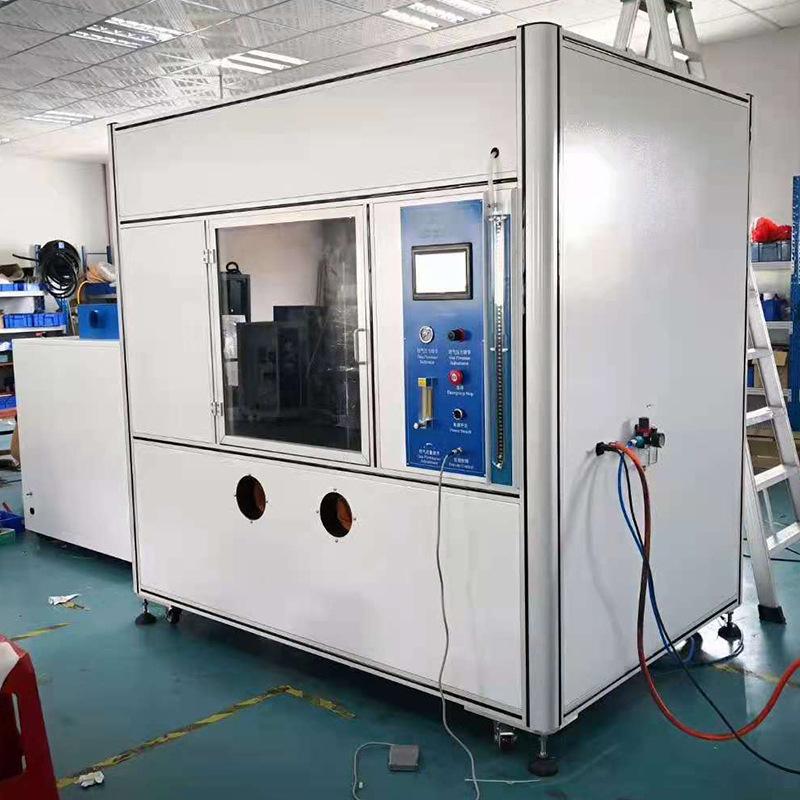

YOUKE YK3261 UL1581 Wire and cable combustion Tester

SEYouKe YK3261 UL1581 Wire and cable combustion TesterSPEC

YouKe YK3261 UL1581 Wire and cable combustion TesterDetails

YouKe YK3261 UL1581 Wire and cable combustion TesterPacking list

- SKU

- NB036463

- test space

- ≥4.0m³

- Dimensions

- 2100*1360*2200mm

- Thermocouple

- (Electrolysis Copper Block 10.0 +/- 0.05g and Thermocouple) Type K thermocouple with 0.5mm diameter stainless steel tube jacket

- Timer

- 0~99H99/99M99/99S99 can be set arbitrarily, the minimum resolution can reach 0.01S

- heating time

- The time required for the test flame to rise from 100 ℃ +/- 2 ℃ to 700 ℃ +/- 3 ℃ is 54s +/- 2s

- test stand

- Made of SUS304 #stainless steel, divided into horizontal bracket and vertical bracket

- Combustion blowtorch

- Meets ASTM D 5025-05 requirements, standard power

- combustion gas

- Purity of at least 98% methane, with customer-supplied gas

- Flow Measurement Range

- 1000ml/min

Executive standard

This testing machine is designed according to the corresponding clauses of Section 1080 (VW-1 Burning Test) and Section 1100 (Horizontal Sample/FT2 Burning Test) of UL1581-2006.

The main function

The UL1581 combustion Test Chamber is suitable for testing the flame retardancy of the insulation layer of wires and cables under abnormal conditions such as overheating and overcurrent. The laboratory consists of a test part and a control part. The control system has a high degree of automation, with automatic ignition and temperature calibration functions, digital display of temperature and time, convenient observation and recording, and stable and reliable use.

Sealed with high anti-corrosion steel plate, sprayed with high anti-corrosion paint, no air circulation during the test

There is a toughened glass observation door on the front of the box, which is convenient for observing the test situation

The operation panel is located on the right side of the observation door, which is convenient for observing the test situation

Internal volume ≥ 4.0m3

Dimensions: 2100*1360*2200mm

Thermal sensor (electrolytic copper block 10.0±0.05g and thermocouple)

K-type thermocouple, equipped with a jacket of 0.5mm diameter stainless steel tube

The intelligent PID temperature control meter is matched with the K-type thermocouple, and its reading can reach 1000°C

Timer: 0 ~ 99H99 / 99M99 / 99S99 can be set arbitrarily, the minimum resolution can reach 0.01S

It takes 54s±2s for the test flame to rise from 100℃±2℃ to 700℃±3℃

Main Fixtures: Test Stand and Burning Blowtorch

Test bracket: made of SUS304# stainless steel, divided into horizontal bracket and vertical bracket

Combustion blowtorch: meet ASTM D 5025-05 requirements, standard power: 500W; flame nozzle diameter: 0.90±0.03mm, flame nozzle length: 1.60±0.05mm, nozzle inner diameter: 9.5mm; nozzle height from air inlet: 100mm±10mm

Low-noise industrial fan, exhaust quickly, the test personnel can not touch the gas at all, harmless to the body

Using PLC control system and large touch screen, the interface is beautiful, easy to operate and easy to understand

Gas: Methane with a purity of at least 98%, provided by the customer

The transmission system is controlled by a stepping motor, and the inclination angle can be set, which is precise and easy to operate

Control System:

(1), mainly including: flow meter, differential pressure meter;

(2), flow meter range: 1000ml/min;

(3), combustion pressure reducing valve: 1;

(4), U-shaped differential pressure gauge: 1 piece.

- 1ASTM 《Standard Test Method for Surface Burning Characteristics of Building Materials》

- 2ISO 4589《Plastics - Determination of burning behaviour by oxygen index - Part 3: Elevated-temperature test》

- 3GB/T 3324-2024《General technical requirements for wooden furniture》

- 4FZ/T 98017-2018《Burning behavior-vertical method tester for textiles》

- 5GB/T 16581-1996《Test method for the determination of oxygen index of insulating liquids》

- 6GB/T 5454-1997《Textiles--Burning behaviour--Oxygen index method》

- 7GB/T 14402-2007《Reaction to fire tests for building materials and products - Determination of the heat of combustion》

- 8GB/T 13489-2008《Rubber coated fabrics - Determination of the burning behaviour》

- 9GB/T 10707-2008《Rubber - Determination of the burning》

- 10GB/T 11049-2008《Burning behaviour of carpets - Tablet test at ambient temperature》

YK3261

YK3261