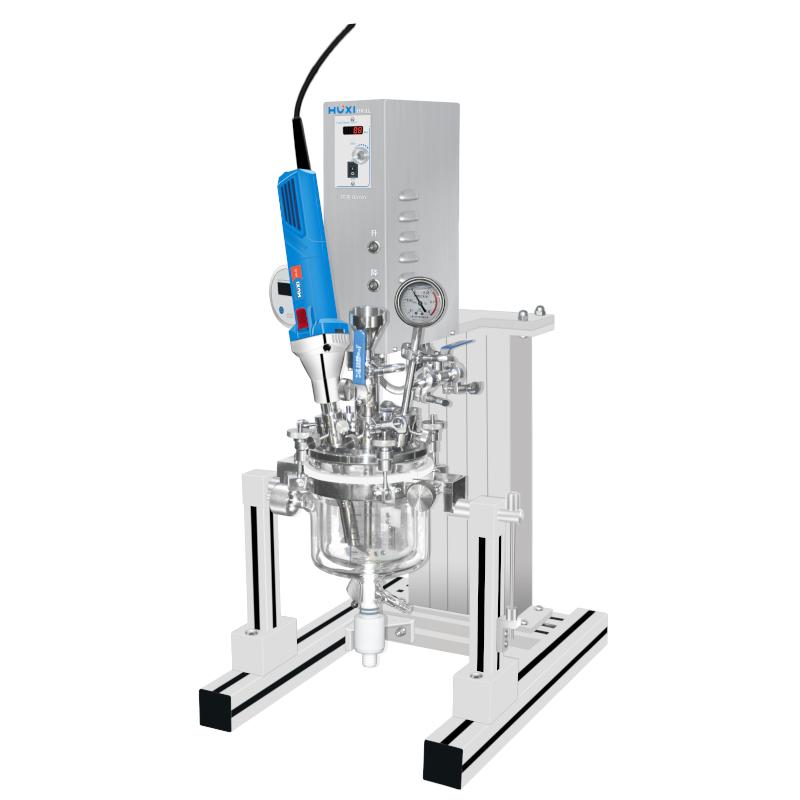

Huxi HR-1L laboratory vacuum emulsification reaction kettle

SEHuXi HR-1L Laboratory vacuum emulsification reaction kettleSPEC

HuXi HR-1L Laboratory vacuum emulsification reaction kettleDetails

HuXi HR-1L Laboratory vacuum emulsification reaction kettlePacking list

- SKU

- NB036494

- Power

- 220V 50/60HZ

- Stirring amount ml

- 300

- Allowable emulsification ml

- 500-1000

- Vacuum can be achieved

- -0.097---0.02mpa

- 处理Viscosity

- 10000mpas

- Stirring speed range

- 0-230rpm

- Impeller configuration

- Anchor Ribbon Scrape Stirring Paste

- Scraper material

- silicone rubber

- Homogeneous motor power

- 500W

- Homogeneous velocity range

- 8000-28000rpm

- Homogeneous working head configuration

- 25DG

- Reaction kettle cover opening

- Homogenizer port + hopper port + temperature measurement port + vacuum port + 3 spare ports

- Lifting bracket travel

- 210mm

- Main contact material with material

- SS316L, Borosilicate Glass, FKM10

- Outer diameter of vacuum port

- 10mm

- Glass kettle jacket inlet and outlet outer diameter

- 12mm

- Allowable environment temperature ℃

- 5-40

- Allowable relative temperature ℃

- 80

- Standard Weight kg

- 37

Applications

Laboratory vacuum emulsification reactor: in a vacuum or pressure environment, to achieve the dispersion, emulsification, homogenization, mixing and other processes of materials. It can be equipped with a variety of effective macro high-viscosity agitators, high-shear homogenization emulsifiers, as well as reliable vacuum sealing systems and temperature control systems, and a variety of sensing and detection systems can simulate industrial production in a laboratory environment. At present, the laboratory processing capacity includes: 1L, 2L and other series. It is used for dispersion, mixing, emulsifying, homogenizing, stirring and dissolving in the laboratory. The whole reaction process of stirring, homogenization, emulsification, dispersion, mixing and other materials can be observed through the glass autoclave under vacuum or pressure conditions, and stainless steel can also be pressurized and homogenized emulsified and dispersed by stainless steel.

Features

production of cheeses, lotions, lotions and the preparation of fats in the cosmetics industry;

Mix solids such as calcium carbonate, talc, titanium oxide, etc. with emulsions;

Lithium battery industry: high-shear dispersion, emulsification or polymer polymerization reaction stirring;

Grinding and dispersing solids and fibers in liquids and polymers. Such as glue strong vacuum stirring;

It can measure the temperature, pressure, viscosity, PH and so on of the material at the same time. It is also possible to heat or cool the material.

HR-1L

HR-1L