Huxi HR-90Z Pilot High-Shear Dispersing Emulsifier with 90T5 working head

SEHuXi HR-90Z/90T5 (electric lift) Pilot High Shear Dispersion MulserSPEC

HuXi HR-90Z/90T5 (electric lift) Pilot High Shear Dispersion MulserDetails

HuXi HR-90Z/90T5 (electric lift) Pilot High Shear Dispersion MulserPacking list

- SKU

- NB036674

- power

- 1500W

- Power

- 220V,50Hz

- throughput

- 10~50L

- Max. Viscosity

- 8000CP

- Speed range

- 50~4000rpm

- speed control

- Frequency conversion speed regulation

- Speed display

- Digital display

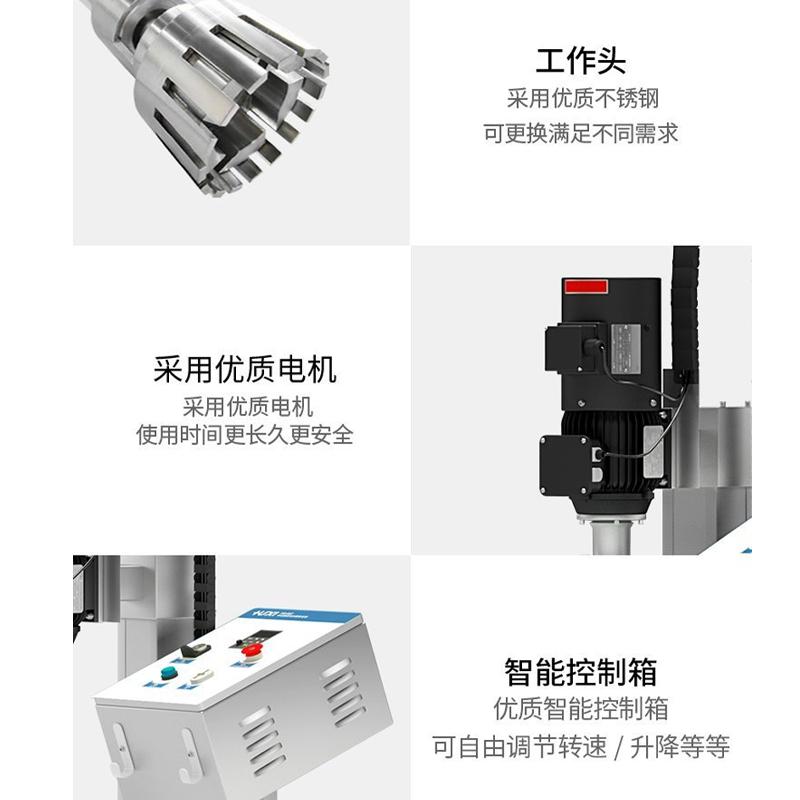

- Contact material

- SS316L

- Bushing material

- PTFE

- Standard head configuration

- 90F/90T5

- Allowable environment temperature

- 5~40℃

- Allowable Relative Humidity

- 80%

- Motor protection level

- IP54

- frequency converter

- Standard

- Overload protection

- Yes.

- Process type

- batch processing

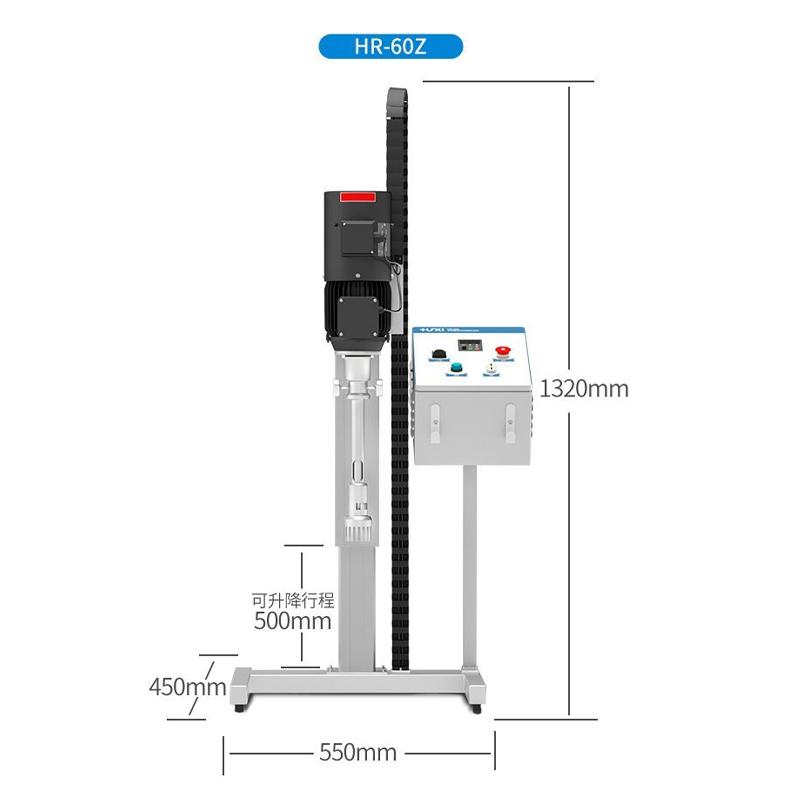

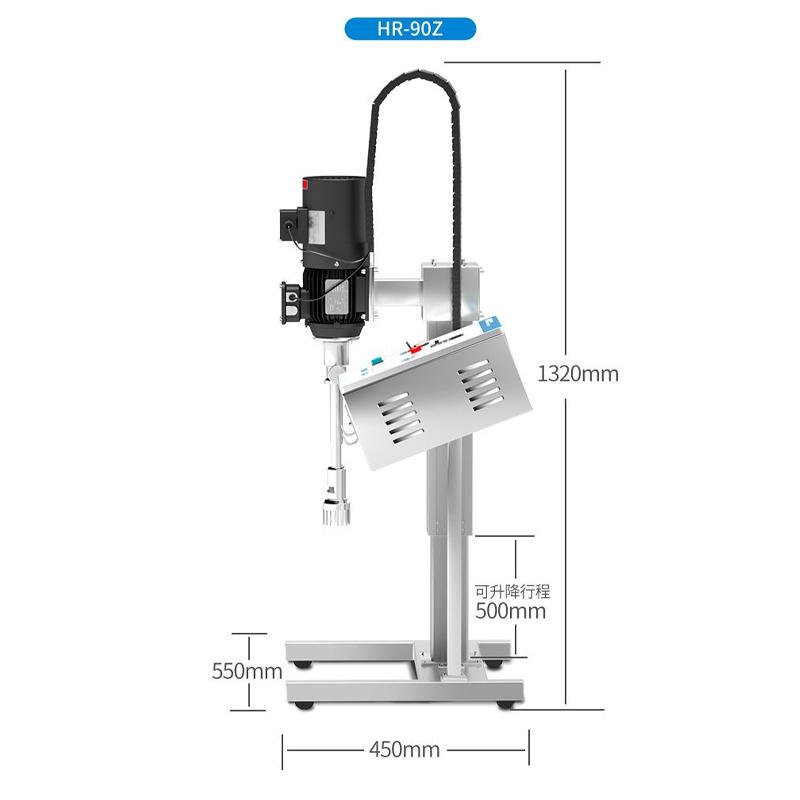

- Lifting method

- electro-hydraulic

- Work frame material

- 316L

- Lifting stroke

- 600mm

- Dimensions

- 750*600*1460mm

- Packaging Dimensions

- 780×630×1460mm

- Encasement

- wooden box

Applications

Pilot-scale high-shear dispersing and emulsifying machine is specially designed for pilot-scale, simulated production and small-batch production in factories. The working head is composed of a high-speed rotating rotor and a precise stator working chamber, relying on high linear speed to generate strong hydraulic shearing. Centrifugal extrusion, high-speed cutting and collision make the materials fully dispersed, emulsified, homogenized, pulverized and mixed in one go, and finally stable and qualified products are obtained.

Features

● A variety of working heads are available to meet different experimental needs;

● The speed adopts frequency conversion speed regulation and digital display mode, the lowest can reach 50rpm;

● Electro-hydraulic lifting method, easy to operate and easy to use;

● The high-speed variable frequency motor realizes the protection function of variable frequency start, which meets the requirements of continuous operation in the experiment;

● The instrument is equipped with a red mushroom head emergency stop button. When the machine is in a fault state, use this button to cut off the power supply, so that the equipment will stop running immediately, so as to protect the safety of people and equipment;

● Wide range of applications: fine chemicals, petrochemicals, pesticides and fertilizers, biomedicine, daily chemicals, food industry and other fields.

HR-90Z/90T5 (electric lift)

HR-90Z/90T5 (electric lift)