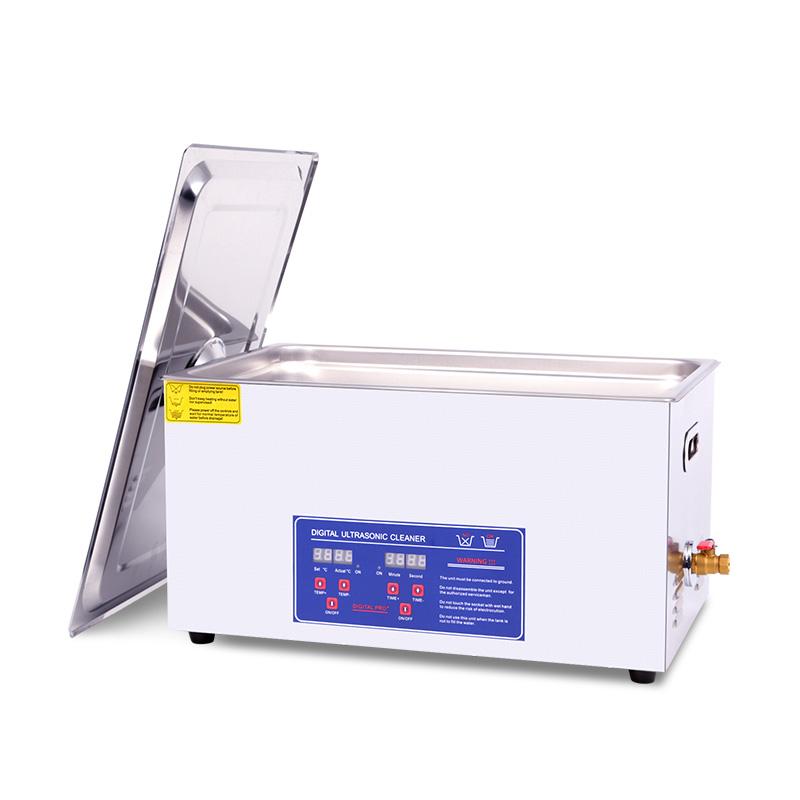

Dksonic PS-80A Ultrasonic Cleaner 22L Digital Timing Heating

SE

dksonic PS-80A Ultrasonic CleanerSPEC

dksonic PS-80A Ultrasonic CleanerDetails

dksonic PS-80A Ultrasonic CleanerPacking list

- SKU

- NB037054

- Inner slot size

- 500*300*150mm

- Dimensions

- 550*330*280mm

- Capacity

- 22L

- Total power

- 480W

- Ultrasonic frequency

- 40KHz

- Heating power

- 500W

- Time setting

- 1-99Min

- Temperature setting range

- 0-80℃

Application

Ultrasonic cleaners have very good advantages over other physical or chemical cleaning, so they are extensiveIt is used in service industry, electronics industry, industry, laboratory, machinery industry, cemented carbide industry, chemical industryindustry and many other fields.

Features

1) Ultrasonic circuit technology has been comprehensively improved, and the circuit of the marking industry has effectively solved the application dilemma of the industry;

2) The cleaning is more refined, and the blind spot of ultrasonic cleaning is effectively solved;

3) High circuit conversion efficiency: 98%, very low reactive power loss;

4) Intelligent humanized control circuit fully guarantees the reliability of the product and prolongs the service life of the product;

5) Humanized digital display power-off memory function, easier and faster operation;

6) The working groove of the product is made of good SUS304 stainless steel for one-time stamping and forming, with long life and beautiful appearance;

7) 6L and above specifications have drainage device to quickly discharge waste liquid

8) SUS304 material special cleaning blue optional;

How to use:

Installation & Preparation:

a) After unpacking, check whether the parts are loose

b) Place the machine in a ventilated and dry place, make sure the machine is in a horizontal position

c) Connect the power plug correctly and make sure the connection is secure (be sure to use a three-pin socket with reliable grounding.)line to ensure safety)

d) Add an appropriate amount of cleaning solution according to the cleaning needs

Cleaning Method:

Normal cleaning can be cleaned with water. When the product has not been cleaned for a long time or there is a lot of dirt, pleaseAdd the appropriate cleaning solution to enhance the super cleaning effect. For longer items, it can be washed in sections.

Serial models

| Model | Inner groove size | Dimensions | capacity | power | Operating frequency | Heating power | Time setting | temperature |

| (L*W*H)mm | (L*W*H)mm | L | W | KHz | W | Min | ℃ | |

| PS-08A | 150×140×65 | 190×170×150 | 1.3 | 60 | 40 | 100 | 1-99 | 0-80 |

| PS-10A | 150×140×100 | 190×170×195 | 2 | 60 | 100 | 1-99 | 0-80 | |

| PS-20A | 240×140×100 | 270×170×220 | 3.2 | 120 | 100 | 1-99 | 0-80 | |

| PS-30A | 300×155×150 | 330×180×280 | 6.5 | 180 | 300 | 1-99 | 0-80 | |

| PS-40A | 300×240×150 | 330×270×280 | 10 | 240 | 300 | 1-99 | 0-80 | |

| PS-60A | 330×300×150 | 360×330×280 | 15 | 360 | 400 | 1-99 | 0-80 | |

| PS-80A | 500×300×150 | 550×330×280 | 22 | 480 | 500 | 1-99 | 0-80 | |

| PS-100A | 500×300×200 | 550×330×330 | 30 | 600 | 500 | 1-99 | 0-80 |

- 1GB/T 31531-2025《Determination of quinoline and isoquinoline in dyestuffs and textile dyeing and finishing auxiliaries》

- 2GB/T 44367-2024《Determination of restricted 2,4-diamino-pyrimidine-3-oxide in cosmetics—High performance liquid chromatography》

- 3GB/T 37640-2019《Determination of chloroacetaldehyde,2,4-dihydroxy-3-methylbenzaldehyde,crotonaldehyde,acetophenone,2-pentylidenecyclohexanone and glutaral in cosmetics—High performance liquid chromatography》

PS-80A

PS-80A