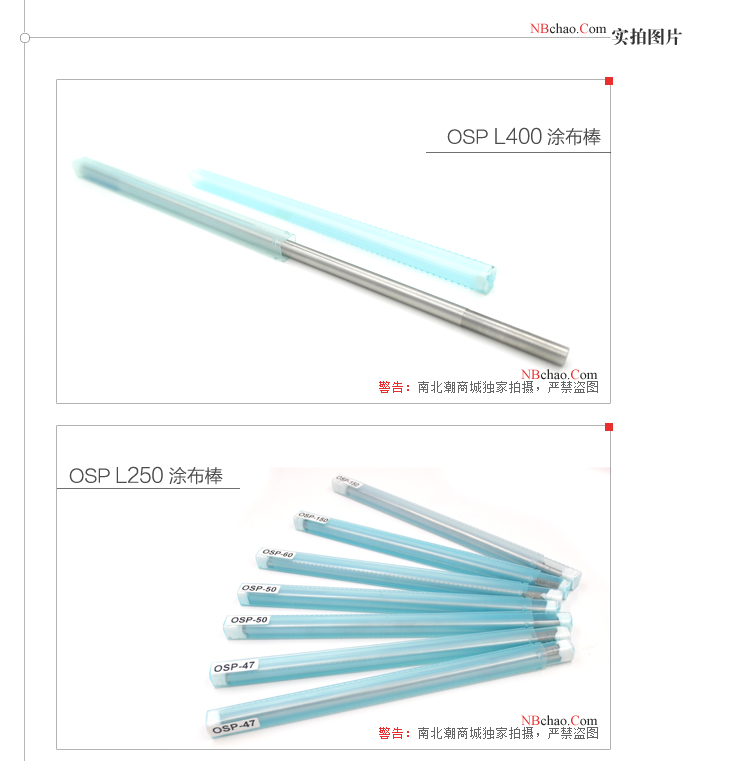

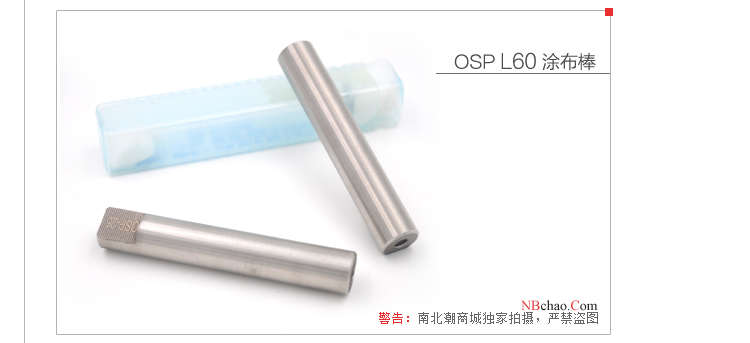

Japan OSP-06/250 paint stick WFT 6μm length 250mm

SEOSP OSP-6/250 coating rodSPEC

OSP OSP-6/250 coating rodDetails

OSP OSP-6/250 coating rodPacking list

- SKU

- NB003712

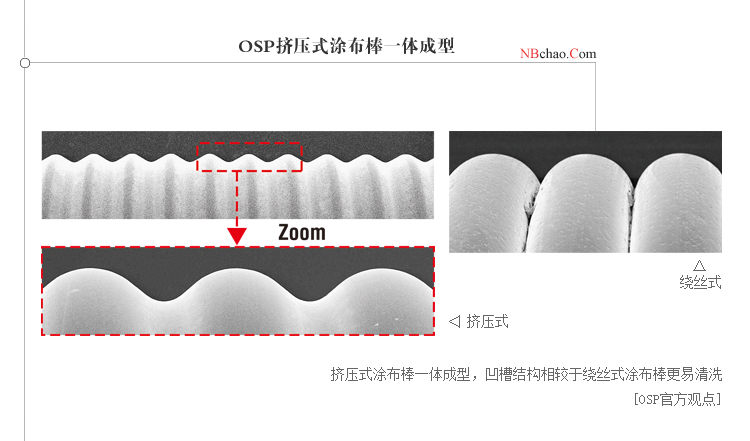

- Production process

- Formed

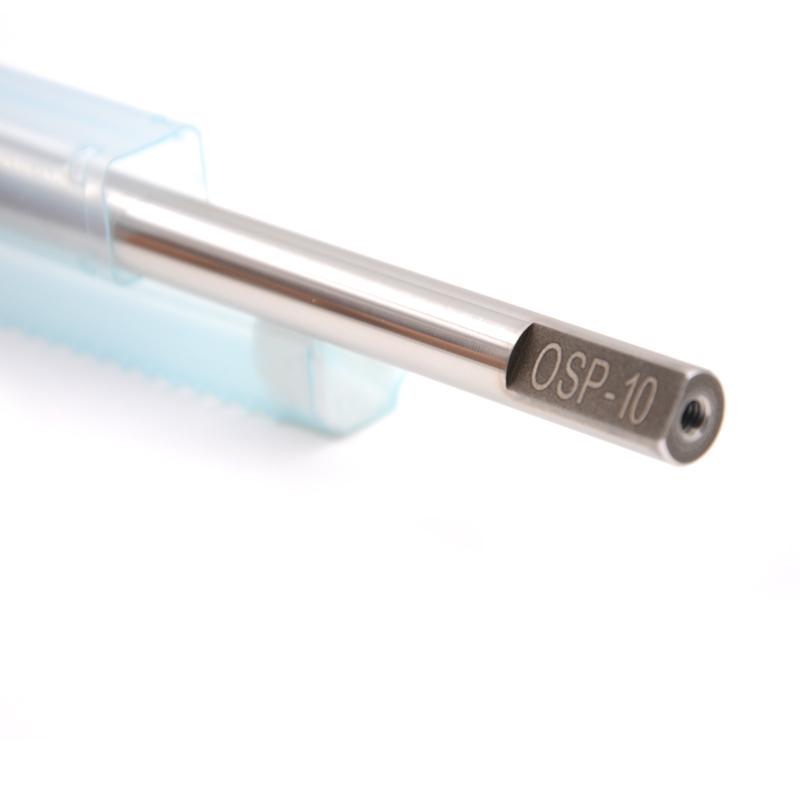

- WFT

- 6μm

- diameter

- 10mm

- Total length

- 250mm

- Application width

- 250mm

- Grip width

- 0

- material

- 304 stainless steel

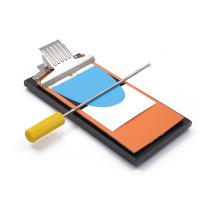

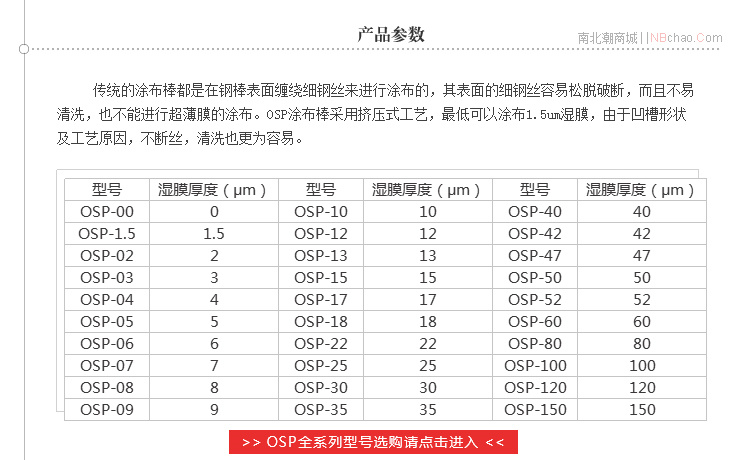

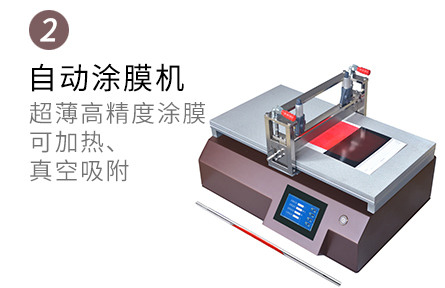

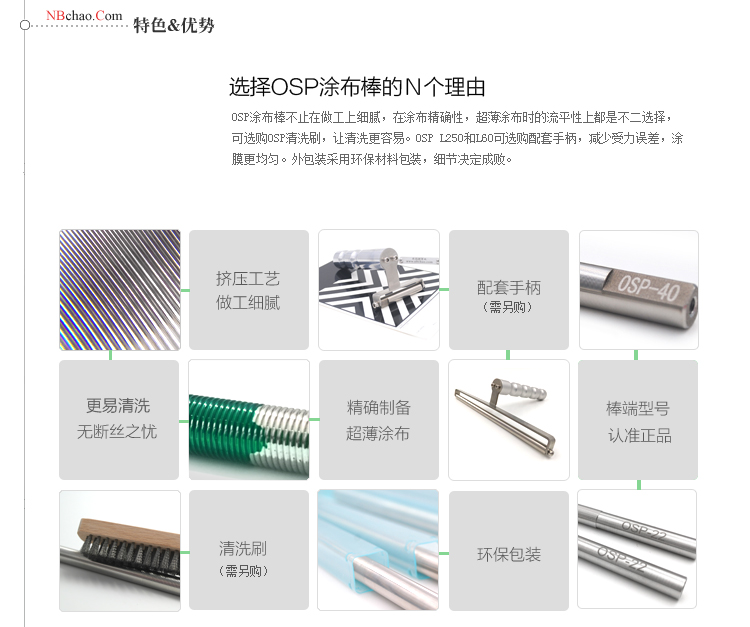

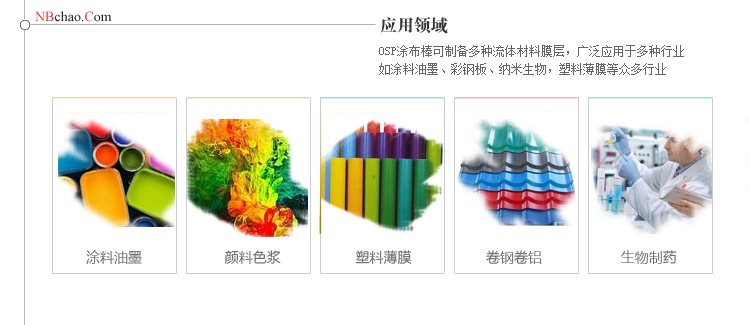

Japan OSP-06/250 paint stick is a manual coating stick, which has the advantages of easy cleaning and no worry of broken wires. For common coating preparation, we usually use automatic coating machines or wet Film Applicators and the more popular manual coating sticks. The coating sticks can choose different wet film thicknesses according to the customer's specific film thickness requirements, and pass through the embossing of the bottom layer. The bed is kept flat, and a certain amount of test fluid is introduced on it by using the hiding power test card, so that a precise wet film coating can be scraped manually by using the coating stick of the specific wet film. OSP-06 Coating Stick is a precision preparer for 6 micron coating thickness with an accuracy of 0.5 micron.

Optional

| |

|  |

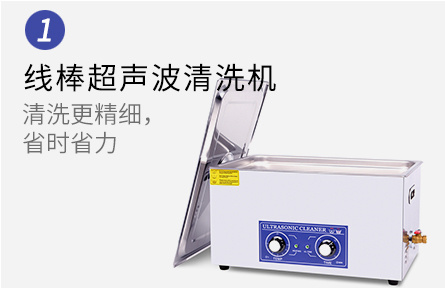

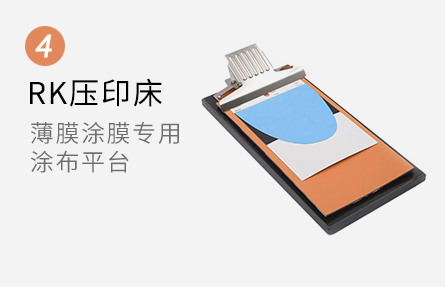

Note: Click on the accessory picture to view Details.

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2HG/T 5370-2018《Waterborne coatings for bicycles》

- 3HG/T 3951-2007《Water based colorants for architectural coatings》

- 4GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 5HG/T 4914-2016《Over laminated pressure sensitive adhesive tape》

- 6GB/T 13217.1-2009《Test method for colour of liquid ink》

- 7GB/T 26461-2011《Gravure ink for paper》

- 8ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

OSP-6/250

OSP-6/250