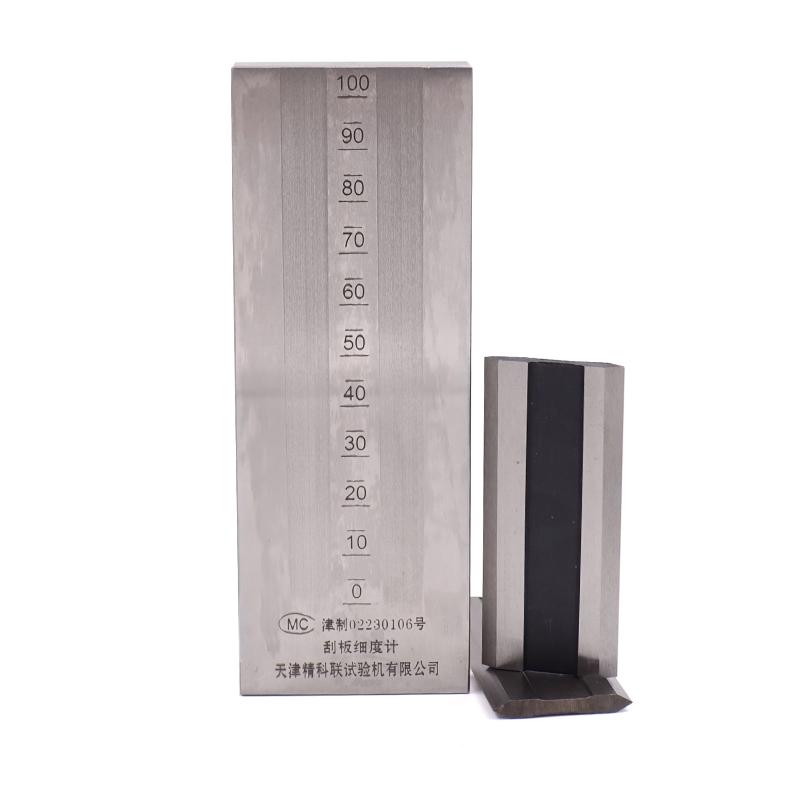

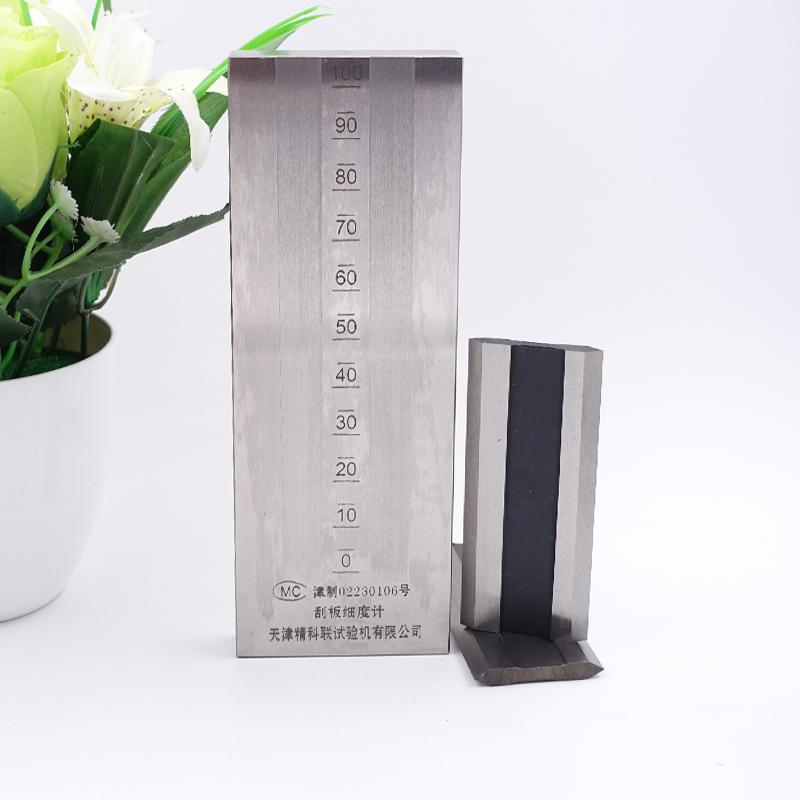

JINGKELIAN QXP 0-50S ISO Fineness of Grind Gauge with Third Party Measurement Certificate

SEISO double-channel Fineness of Grind Gauge, range 0~50 μm, scale unit μm, Graduation 5 µm, scraper material stainless steel, Applicable standard ISO1524-1983 (E).

$247.00/set

PromotionLoading...

Coupon

Model:

Similar products

-

JINGKELIAN QXP 0-50S ISO Fineness of Grind Gauge Fineness gauge 0~50μm/5μm$ 184.00SE

JINGKELIAN QXP 0-50S ISO Fineness of Grind Gauge Fineness gauge 0~50μm/5μm$ 184.00SE -

MODERNER QXD-50 small double-channel qxd Fineness gauge 50 micron Coating Fineness gauge

MODERNER QXD-50 small double-channel qxd Fineness gauge 50 micron Coating Fineness gauge -

TRUIT TR 1202/050 double-channel Coating Fineness meter 0~50μm$ 189.00SE

TRUIT TR 1202/050 double-channel Coating Fineness meter 0~50μm$ 189.00SE -

TQC VF2112 double-channel Fineness gauge 0-50 µm with calibrated certificate$ 1054.00SE

TQC VF2112 double-channel Fineness gauge 0-50 µm with calibrated certificate$ 1054.00SE -

Pushen ISO-50um stainless steel double-channel Fineness Meter 0-50μm$ 193.00SE

Pushen ISO-50um stainless steel double-channel Fineness Meter 0-50μm$ 193.00SE

JingKeLian QXP 0-50S ISO double-channel Fineness of Grind GaugeSPEC

JingKeLian QXP 0-50S ISO double-channel Fineness of Grind GaugeDetails

JingKeLian QXP 0-50S ISO double-channel Fineness of Grind GaugePacking list

- SKU

- NB037188

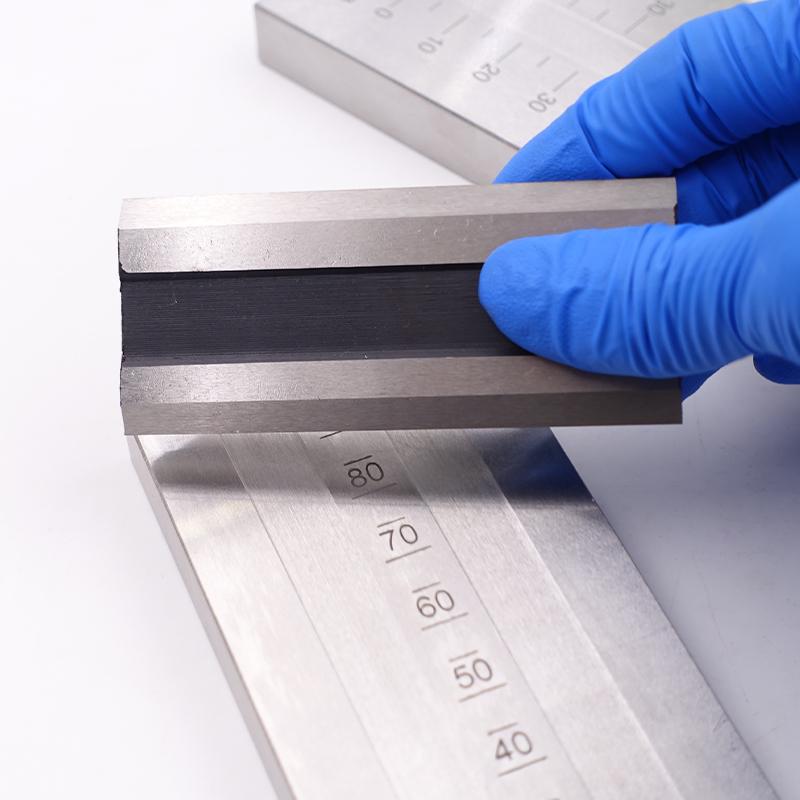

- Scraper type

- double-channel

- range

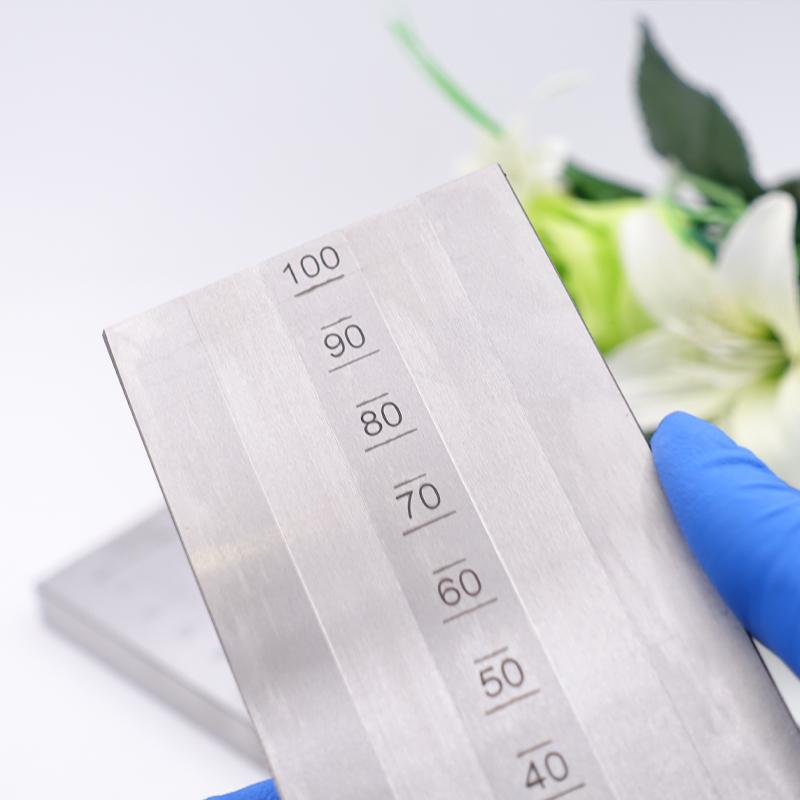

- 0 ~ 50µm

- Scale unit

- mm

- Graduation

- 5µm

- Scraper material

- stainless steel

- Scraper size

- 175*65*13mm

- Groove size

- 140*12.5mm

- Scraper size

- 90*40*6mm

- Applicable standard

- ISO1524-1983(E)

QXP 0-50S

ISO double-channel Fineness of Grind Gauge

ISO double-channel Fineness of Grind Gauge, range 0~50 μm, scale unit μm, Graduation 5 µm, scraper material stainless steel, Applicable standard ISO1524-1983 (E).

The Fineness of Grind Gauge is manufactured in accordance with the relevant provisions of the international standard ISO1524-1983 (E), and is used for the determination of the particle size of paint and related products. There are two types of Fineness of Grind Gauge, single slot and double slot.

Models

| Optional models | Maximum range | Minimum scale value | Recommended range |

| single slot | 100μm | 10μm | 40~90μm |

| 50μm | 5μm | 15~40μm | |

| 25μm | 2.5μm | 5~15μm | |

| double slot | 100μm | 10μm | 40~90μm |

| 50μm | 5μm | 15~40μm |

Accuracy standard

| technical indicators | Score standard error | Groove Ratio Error | Shape accuracy | Surface roughness | |||

| Range | error | ratio | error | ||||

| scraper | single slot | 100μm | < 2.5μm | 1.0138889 | <2.5μm | front | front |

| 50μm | < 2.5μm | 1.9861111 | < 2.5μm | flatness tolerance | 0.1 | ||

| 25μm | <2μm | 3.9305556 | < 2μm | 0.012 | groove | ||

| double slot | 100μm | <2.5μm | 1.0138889 | < 2.5μm | Lateral Straightness Tolerance | 0.2Ra=1.6 | |

| 50μm | <2.5μm | 1.9861111 | < 2.5μm | 0.001 | |||

| scraper | Blade Straight Tolerance | 2um | |||||

| Surface roughness | Ra0.4 | ||||||

Precautions

1. The front of the scraper can be used as a daily inspection of the straightness of the scraper;

2. Clean the scraper after use, apply anti-rust oil and put it in the box for storage;

3. The front of the scraper and the edge of the scraper must not be bumped;

4. The Grindometer should be calibrated in our factory after one year of use.

FAQ

QCan the Fineness of Ground Gauge be measured for emulsion?

A

Yes. The specific specification and range should be selected according to your estimate or test requirements.

Knowledge

Standard

- 1GB/T 17001.3-2025《Anti-counterfeiting printing ink—Part 3:Thermochromic anti-counterfeiting printing ink》

- 2HG/T 5173-2017《Waterborne primer for application on rusty substrates》

- 3WJ 2669-2005《Specification for cathode electrophoresis paint for shell》

- 4GB/T 42541-2023《Coated steel pipes for gas piping》

- 5GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 6HG/T 3349-2003《Various colour phenolic enamel》

- 7GB/T 5211.17-1988《Comparison of contrast ratio(hiding power)of white pigments》

- 8HG/T 4758-2014《Water-based acrylic resin coatings》

QXP 0-50S

QXP 0-50S