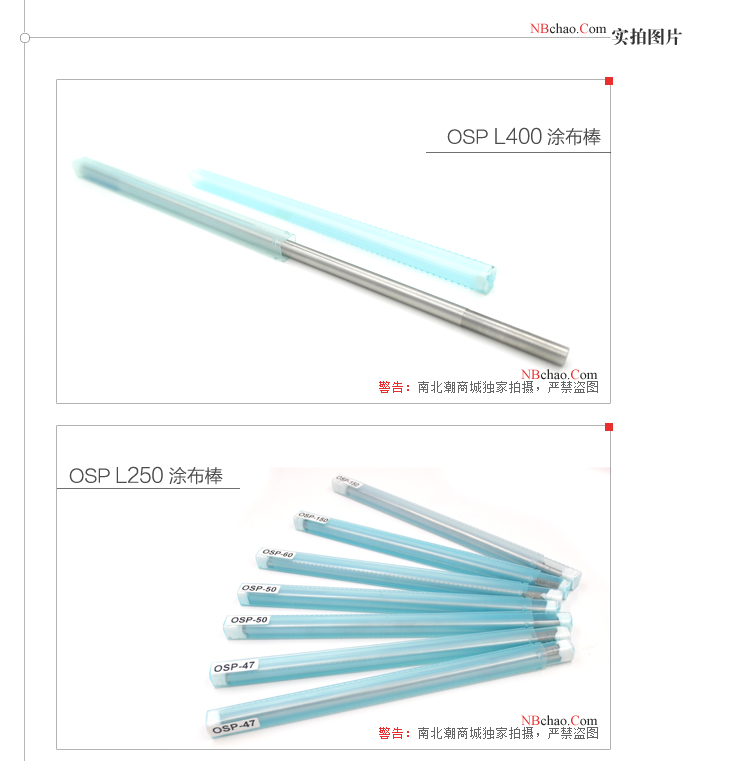

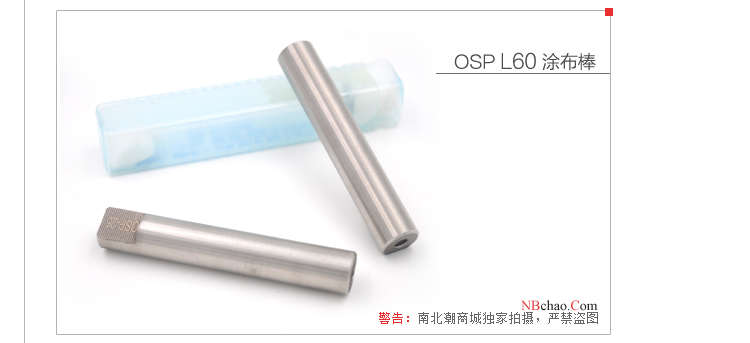

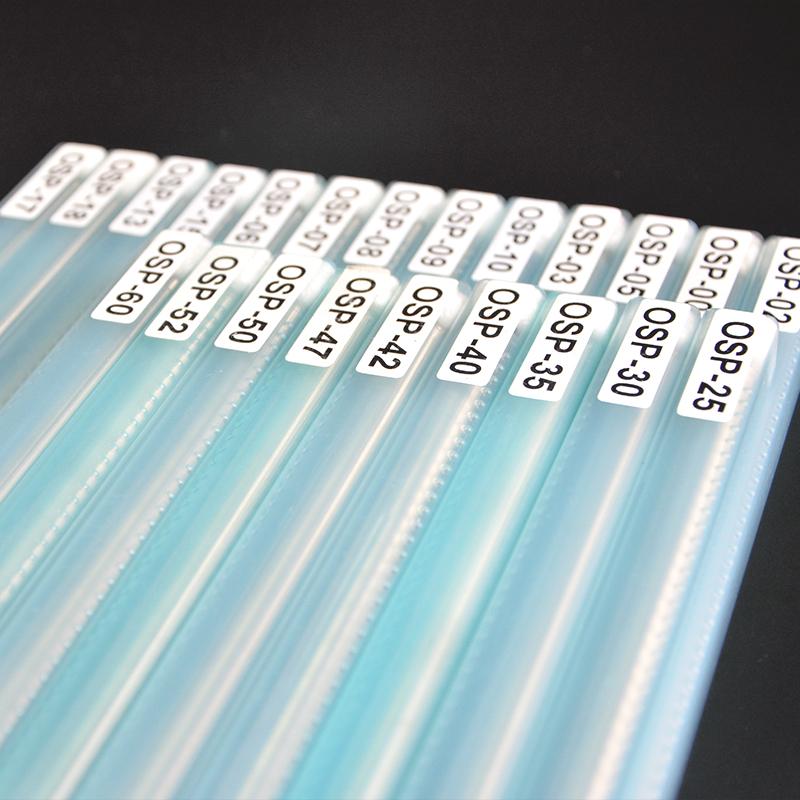

Japan OSP-1.5/400 A-Bar WFT 1.5μm length 400mm

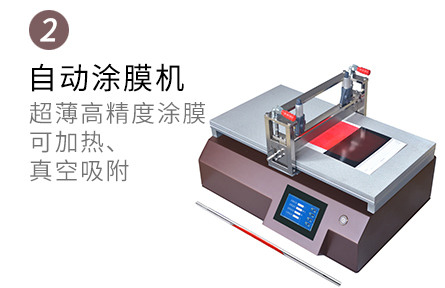

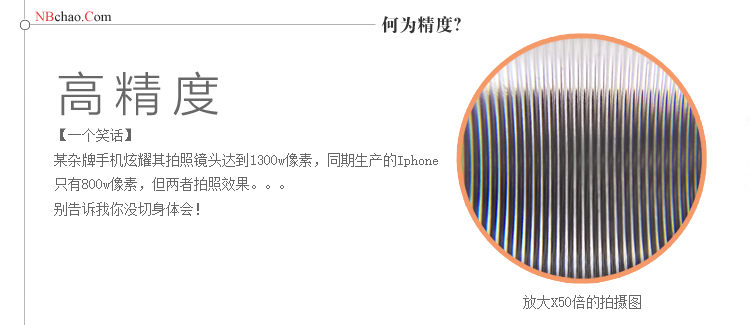

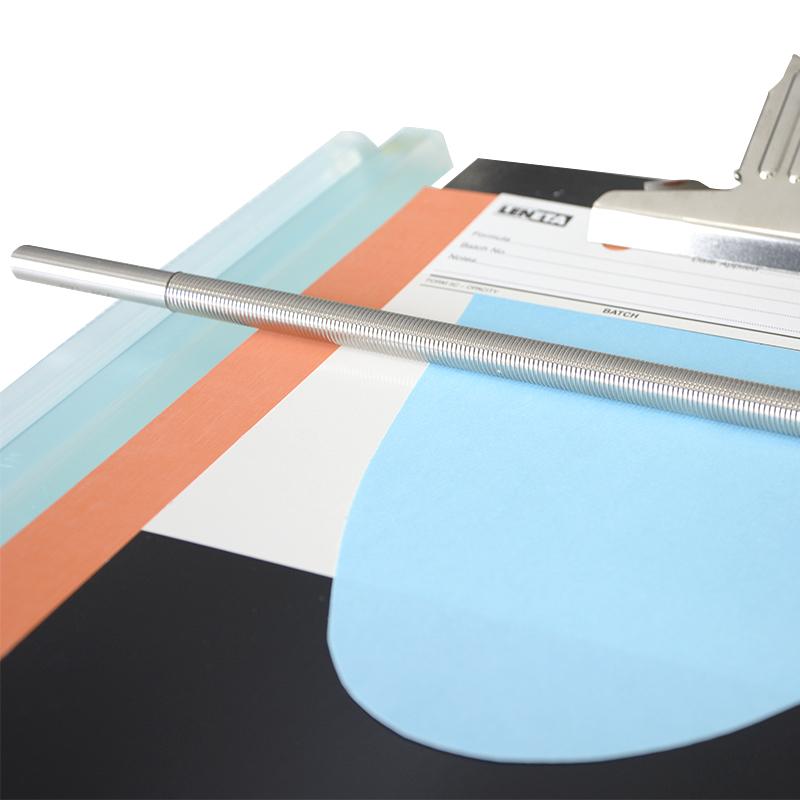

SEThe lowest film thickness under OSP, can be prepared for 1.5 micron wet-film, suitable for users who need ultra-thin film, can be hand-scraped with Film Applicator, ultra-thin wet-film is recommended to pass Film Applicator to reduce manual pressure, shake and uniform speed problems caused by deviation.

$173.00/piece

PromotionLoading...

Coupon

Model:

Similar products

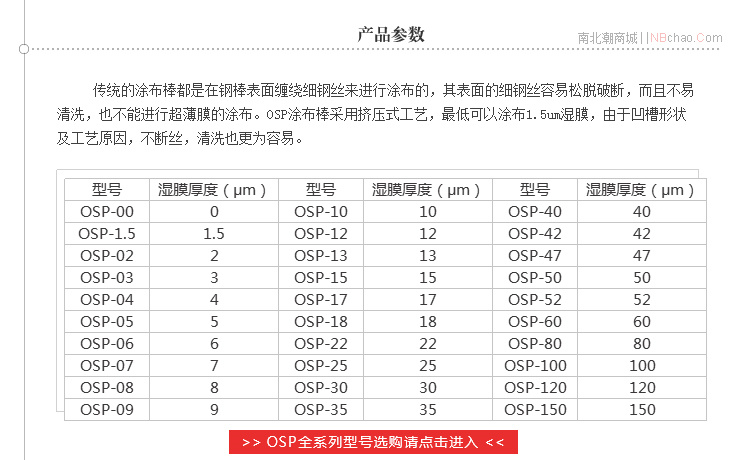

OSP OSP-1.5/400 coating rodSPEC

OSP OSP-1.5/400 coating rodDetails

OSP OSP-1.5/400 coating rodPacking list

- SKU

- NB003733

- Production process

- Formed

- WFT

- 1.5µm

- diameter

- 10mm

- Total length

- 400mm

- Application width

- 300mm

- Grip width

- 50+50mm

- material

- 304 stainless steel

OSP-1.5/400

coating rod

The lowest film thickness under OSP, can be prepared for 1.5 micron wet-film, suitable for users who need ultra-thin film, can be hand-scraped with Film Applicator, ultra-thin wet-film is recommended to pass Film Applicator to reduce manual pressure, shake and uniform speed problems caused by deviation.

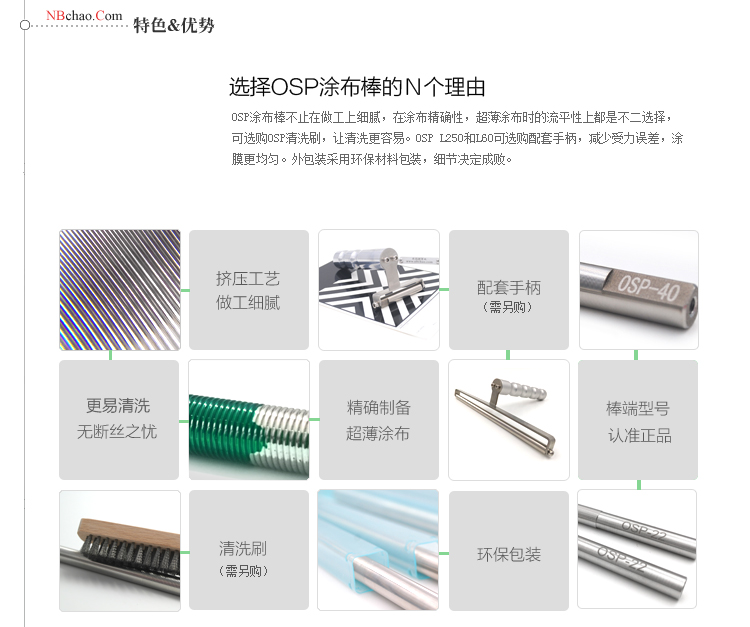

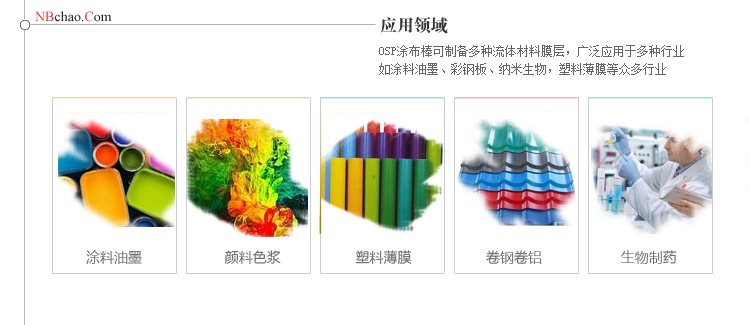

Japan OSP-1.5/400 A-Bar is well received by users in the fields of industrial anti-corrosion coatings, automotive coatings, waterproof coatings, additives, plastic films, daily chemicals, and electrochemistry. The OSP 1.5 micron ultra-thin coating rod is currently the thinnest coating rod in NBCHAO Mall except (light rod: 0 micron). If you need to choose an ultra-thin coating stick, this model is the preferred choice.

Optional

| |

|  |

Note: Click on the accessory picture to view Details.

FAQ

QSpreader dry-film thickness is about 0.5-1 μm. Which kind of wire rod is suitable for you, please recommend it?

A

Choose the 1.5 micron rod number of the OSP.

QIs the thinnest rod 2 microns?

A

No, OSP also has 1.5 microns.

QSome of the added inorganic particles will reach 1 or 2 microns. Yes, as long as they contain solid particles, scratches are inevitable?

A

The principle of the film applicator is that the size of the groove controls the film thickness, and the particle fineness through the groove cannot be greater than the size of the groove of the Applicator rod, otherwise it may scratch

QDoes the Spreader have 1μm Film thickness? Which model?

A

Hello, the thinnest film thickness rod number at present is the 1.5μm scraper rod of Japan OSP, OSP-1.5.

QCan this coating rod be prepative of multi-layer ultra-thin film?

A

The wire rod can be prepared for 1.5 micron ultra-thin film. Everyone must know it, but another advantage of it is multi-layer film, which is much better than I-shaped film applicator. But multi-layer film tests the flatness of the previous layers of film drying. Generally, the film thickness (such as less than 10 microns/layer) is too thin to control. The wire rod with Film Applicator is a very good solution, eliminating the problem of uneven pressure and speed of hand scraping.

QDoes the OSP film scraper meet the ASTMD823 standard?

A

The OSP-1.5/400 film scraper can refer to

QI want to use the Spreader in Adhesive. The viscosity of my glue is about 4000cps. Is this viscosity suitable?

A

The choice of this wire scraper is determined by the fluid wet film thickness you want to Spreader. For the method of calculating the wet film thickness, please refer to the calculation formula on the detailed page or the wet film thickness calculator. It is common for Adhesive to use a wire scraper manual Spreader. Excessive viscosity does cause difficulty and levelling of scraping samples. But this is not the main factor. In fact, users of Adhesive use this type of wire scraper a lot.

QIs the film of this scraper the thinnest?

A

Hello, yes.

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

Standard

- 1GB/T 1727-2021《General methods for preparation of coating films》

- 2GB/T 17001.6-2022《Anti-counterfeiting printing ink—Part 6:Infrared excitation fluorescence anti-counterfeiting printing ink》

- 3GB/T 7044-2022《Colour carbon black》

- 4HG/T 5370-2018《Waterborne coatings for bicycles》

- 5HG/T 3951-2007《Water based colorants for architectural coatings》

- 6GB/T 13217.1-2020《Test method for colour and tinctorial strength of ink》

- 7GB/T 13217.1-2009《Test method for colour of liquid ink》

- 8GB/T 26461-2011《Gravure ink for paper》

- 9ASTM D823-2018《Paints, varnishes and related products of uniform thickness on the test board》

OSP-1.5/400

OSP-1.5/400