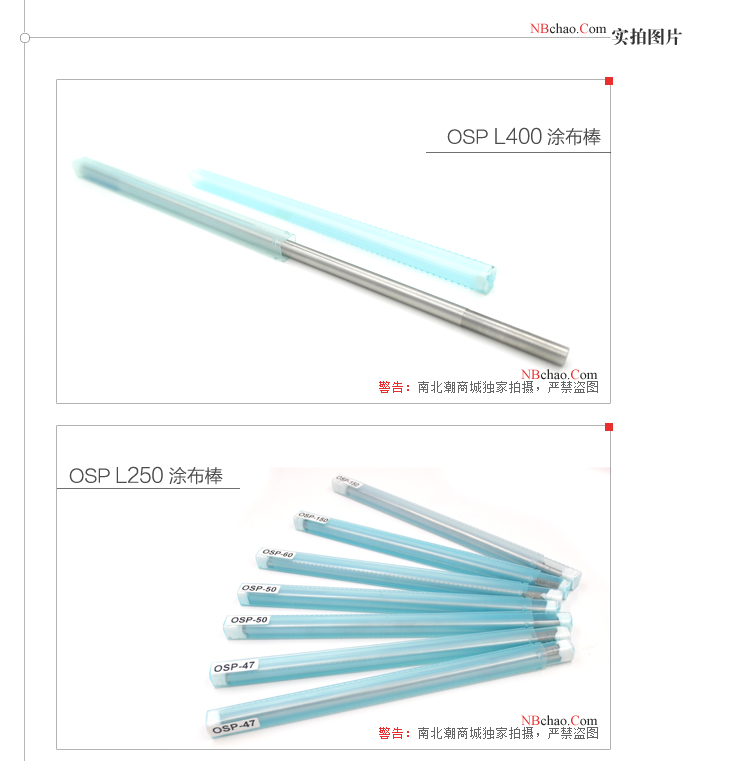

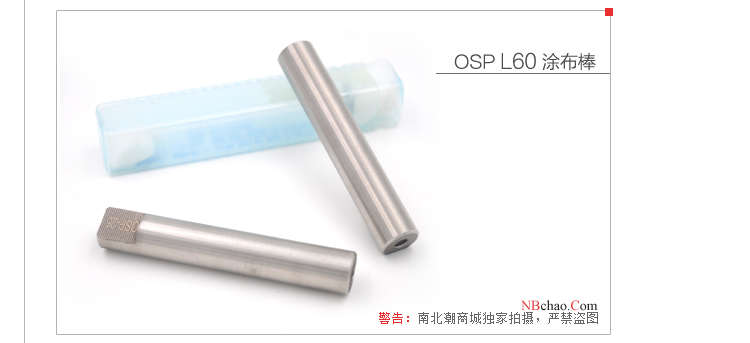

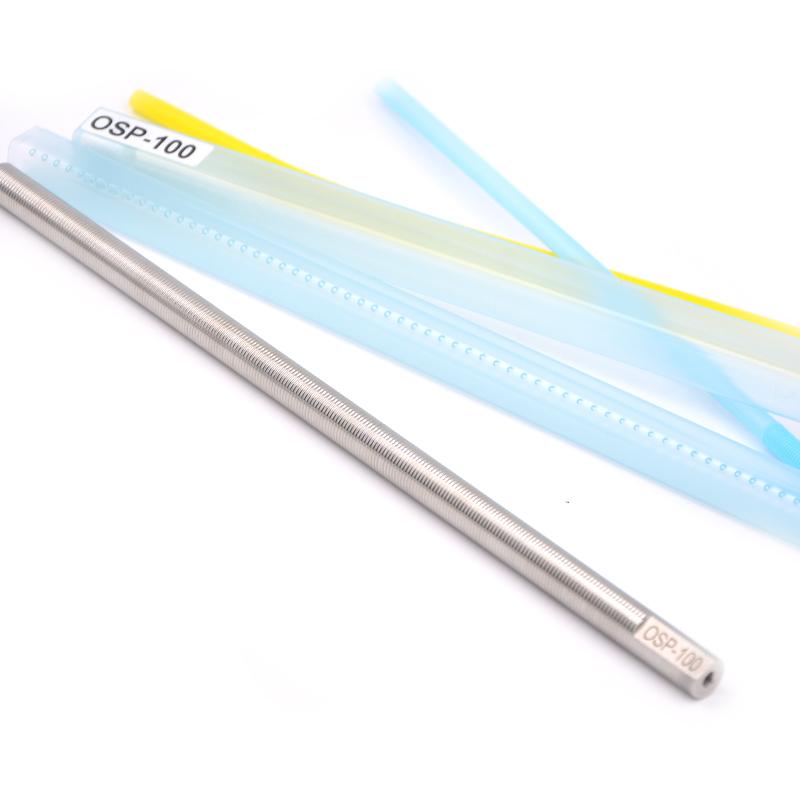

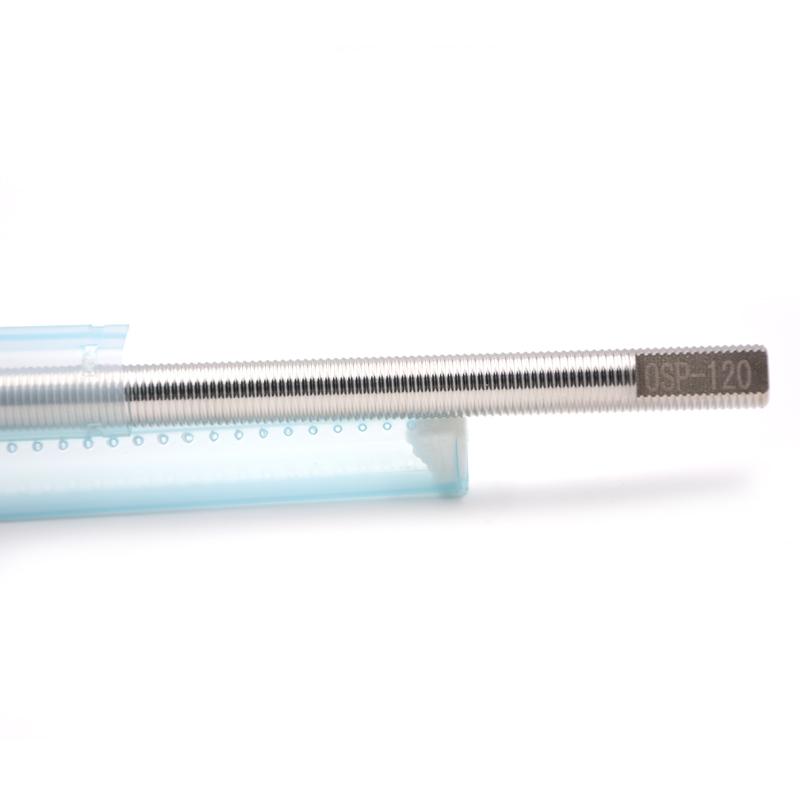

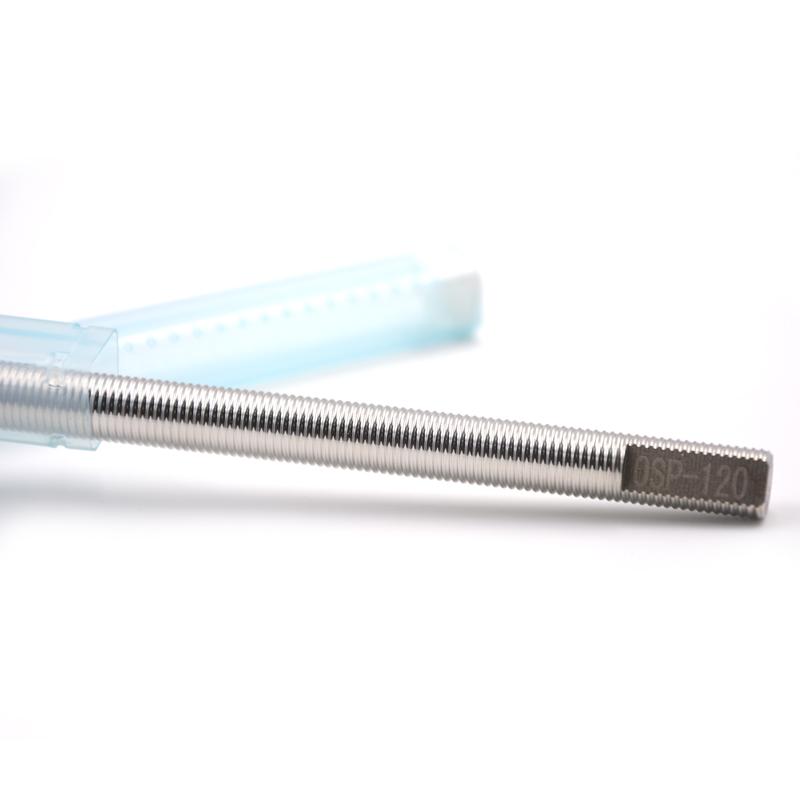

The production process is formed, the wet film thickness is 100μm, the diameter is 10mm, the Total length is 250mm, the application width is 250mm, the grip width is 0, and the material is 304 stainless steel.

$153.00/piece

PromotionLoading...

Coupon

Model:

Similar products

-

RDS 40 #1/2 "Spreader film thickness 91.4μm Wire diameter 1.02mm$ 181.00SE

RDS 40 #1/2 "Spreader film thickness 91.4μm Wire diameter 1.02mm$ 181.00SE -

UK RK KHC.10.8 coating rod WFT 100μm blue rubber head No. 8 rod$ 153.00SE

UK RK KHC.10.8 coating rod WFT 100μm blue rubber head No. 8 rod$ 153.00SE -

UK RK KHC.11.8 coating rod wet film thickness 100μm blue rubber head No. 8 rod$ 168.00SE

UK RK KHC.11.8 coating rod wet film thickness 100μm blue rubber head No. 8 rod$ 168.00SE -

RDS 44 #1/4 "wire-wound Mayer Rods film thickness 100.6μm Wire diameter 1.12mm$ 156.00SE

RDS 44 #1/4 "wire-wound Mayer Rods film thickness 100.6μm Wire diameter 1.12mm$ 156.00SE -

Japan OSP-100/60 Applicator rod WFT 100μm length 60mm$ 116.00SE

Japan OSP-100/60 Applicator rod WFT 100μm length 60mm$ 116.00SE

OSP OSP-100/250 coating rodSPEC

OSP OSP-100/250 coating rodDetails

OSP OSP-100/250 coating rodPacking list

- SKU

- NB003739

- Production process

- Formed

- WFT

- 100µm

- diameter

- 10mm

- Total length

- 250mm

- Application width

- 250mm

- Grip width

- 0

- material

- 304 stainless steel

OSP-100/250

coating rod

The production process is formed, the wet film thickness is 100μm, the diameter is 10mm, the Total length is 250mm, the application width is 250mm, the grip width is 0, and the material is 304 stainless steel.

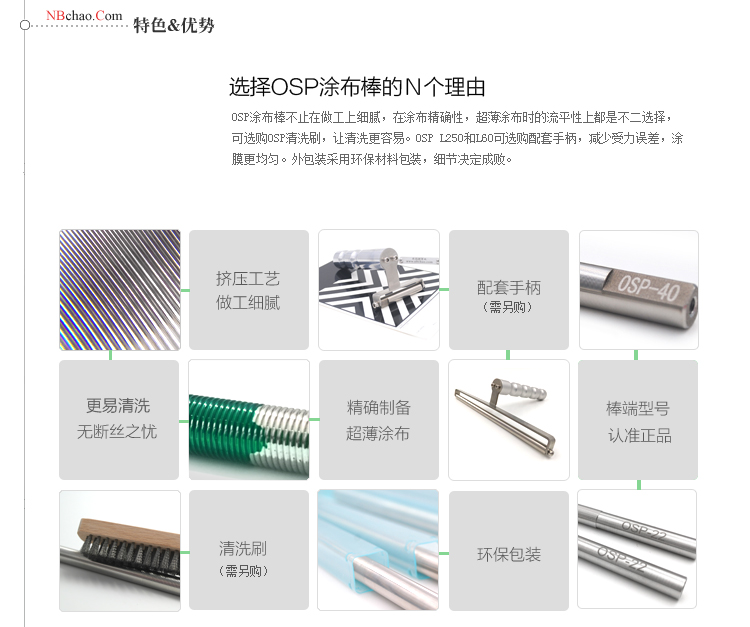

The significant difference between the Japanese OSP-100/250 hand-coated wire rod and the wire-wound wire rod coater is that it is made of stainless steel for extrusion molding, and the wet film thickness of the Japanese OSP-100/250 hand-coated wire rod 100μm length 250mm.

Optional

| |

|  |

Note: Click on the accessory picture to view Details.

FAQ

QCan this wire rod be used to prepare an interior-wall coating test board?

A

Sure.

QAre all Applicator rods available for inspection in the GB/T 13217.1 standard?

A

Not necessarily, but this OSP-100/250 Applicator rod can be considered.

QCan this scraper be used to coat organic polymer conductive films?

A

Yes, the specific selection can be selected by the appropriate rod number corresponding to the rod model and film thickness, by optimizing a series of factors such as wet film thickness, Spreader speed, surfactant concentration, ethylene glycol concentration, film heat treatment temperature, etc., so that It is worth the conductive film compound requirements.

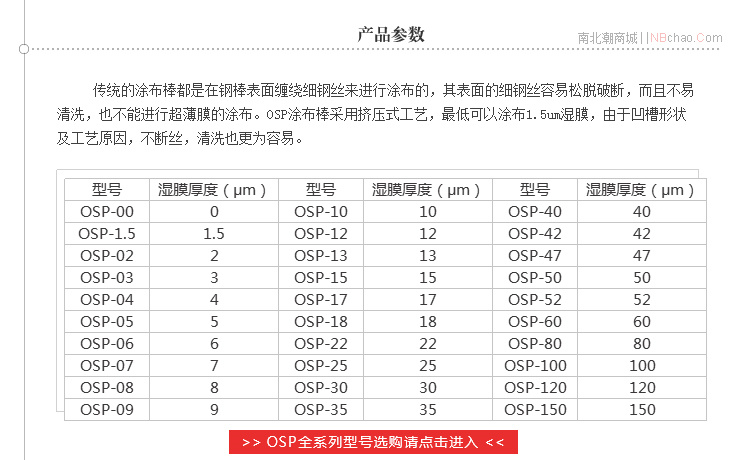

QWhat is the difference between a wire scraper and a formed scraper?

A

Hello, the formed scraper is different from the traditional wired scraper. The surface is not wound, but is made by embossing process. The thinnest formed scraper Spreader can reach a wet film thickness of 1.5 microns.

QCan this wet film scraper be used to make emulsion paint?

A

Hello, it's OK.

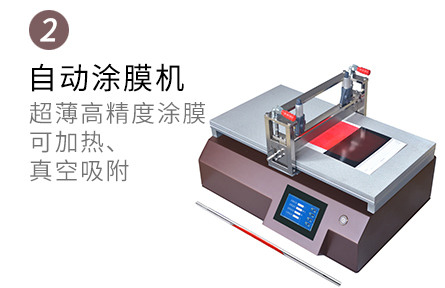

QIs the film better with a scraper or a Film Applicator?

A

The advantage of the Applicator rod is that it is accurate and can be coated with a wet film thickness as small as 1um and as much as about 200um. Film Applicator is mainly used when the film thickness requirements for coating are not high and the film thickness is relatively thick. In fact, to prepare more than 200 wet films, industry customers are more likely to use Film Applicator.

QApplicator rods are used for film testing on covering power paper?

A

Yes oh

Knowledge

- 1Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

Standard

- 1YS/T 680-2016《Powder for coating aluminium alloy extruded profiles for architecture》

- 2HG/T 2006-2006《Thermosetting powder coatings》

- 3GB/T 34676-2017《Interior wall coatings for children's room decorating》

- 4GB/T 1727-2021《General methods for preparation of coating films》

- 5HG/T 20720-2020《Construction and acceptance specification of waterborne anti-corrosion coatings for steel structures in industrial buildings》

- 6HG/T 5370-2018《Waterborne coatings for bicycles》

- 7HG/T 3951-2007《Water based colorants for architectural coatings》

- 8GB/T 9757-2001《Solvent-thinned coatings for exterior wall》

- 9GB/T 9755-2014《Synthetic resin emulsion coatings for exterior wall》

- 10GB/T 9756-2018《Synthetic resin emulsion coatings for interior wall》

OSP-100/250

OSP-100/250