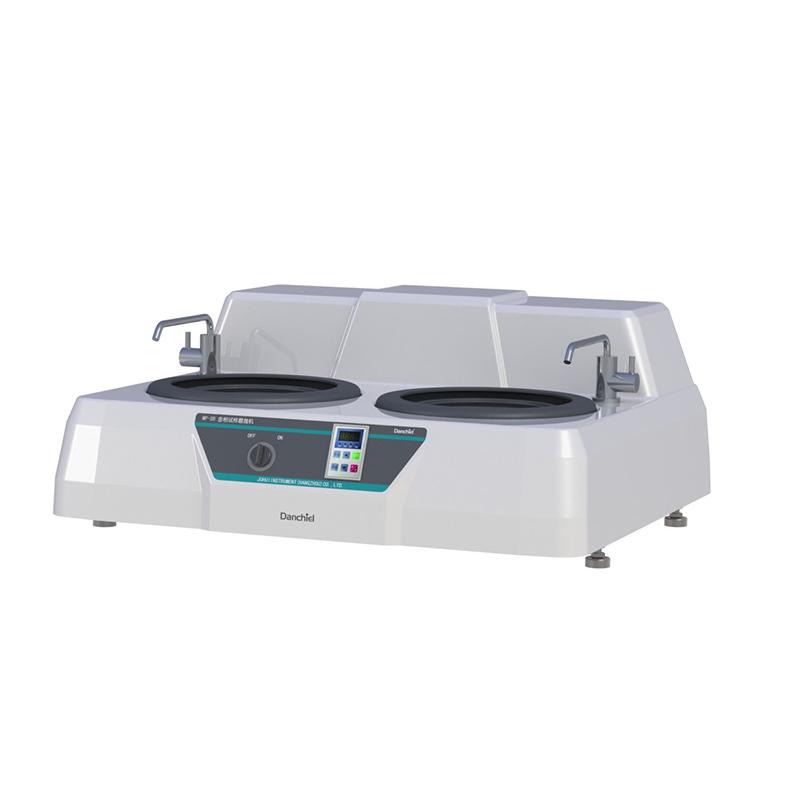

HAOXINDA MP-2B Metallographic polish-grinding machine

SEHaoXinDa MP-2B Metallographic polish-grinding machineSPEC

HaoXinDa MP-2B Metallographic polish-grinding machineDetails

HaoXinDa MP-2B Metallographic polish-grinding machinePacking list

- SKU

- NB037621

- Grinding disc diameter

- Standard φ 203mm (other specifications customized)

- disc speed

- 50-1000R/min (stepless speed regulation)

- Grinding disc swirling/spinning direction

- forward and reverse

- Power Supply

- Voltage: 220V Frequency: 50HZ

- motor

- 0.55KW

- Dimensions

- 730×765×320mm

- Weight

- 42Kg

Overview

In the process of metallographic sample preparation, the grinding and polishing of the sample is the required process, and the surface of the sample can be as bright as a mirror after grinding and polishing. The MP-2B metallographic sample grinding and polishing machine adopts frequency converter speed regulation, which can make the speed of the grinding and polishing disc infinitely adjustable between 50-1000r/min, and the grinding and polishing process of the sample can be completed by replacing the metallographic sandpaper and polishing fabric, showing a wider range of applications. Double-disc design, can be operated by two people at the same time, the shell adopts the overall blister technology, the appearance is novel, with the characteristics of stable rotation, low noise, convenient operation, high work efficiency, etc., and comes with a cooling device, which can cool the sample when grinding and polishing, so as to prevent the metallographic structure from being damaged due to overheating of the sample. It is suitable for metallographic laboratories in factories, colleges and universities, and scientific research units.

Features

1. The shell is made of high-end ABS integrated molding, with novel appearance and high-end atmosphere.

2. The faucet adopts all-copper chrome plating process, which has good corrosion resistance.

3. Stepless speed regulation, convenient and fast to meet a variety of needs.

4. Double-disc design makes sample preparation efficiency more effective.

5. The grinding and polishing disc can be rotated clockwise or counterclockwise to meet different needs

MP-2B

MP-2B