HUXI HJQ-2 Pneumatic Stirrer dissolved Impeller blade 30mm Rod length 350mm

SE-

HUXI HJQ-2 Explosion-proof Pneumatic Stirrer dissolved Impeller blade 150mm Rod length 350mm$ 1305.00SE

HUXI HJQ-2 Explosion-proof Pneumatic Stirrer dissolved Impeller blade 150mm Rod length 350mm$ 1305.00SE -

HUXI HJQ-2 Explosion-proof Pneumatic Stirrer dissolved Impeller blade 120mm Length 350mm$ 1299.00SE

HUXI HJQ-2 Explosion-proof Pneumatic Stirrer dissolved Impeller blade 120mm Length 350mm$ 1299.00SE -

HUXI HJQ-2 Explosion-proof Pneumatic Stirrer dissolved Impeller blade 100mm Rod length 350mm$ 1290.00SE

HUXI HJQ-2 Explosion-proof Pneumatic Stirrer dissolved Impeller blade 100mm Rod length 350mm$ 1290.00SE -

HUXI HJQ-2 Chemical Stirrer dissolved Impeller Slurry 80mm Rod length 350mm$ 1280.00SE

HUXI HJQ-2 Chemical Stirrer dissolved Impeller Slurry 80mm Rod length 350mm$ 1280.00SE -

HUXI HJQ-2 Laboratory Stirrer dissolved Impeller blade 60mm Rod length 350mm$ 1277.00SE

HUXI HJQ-2 Laboratory Stirrer dissolved Impeller blade 60mm Rod length 350mm$ 1277.00SE

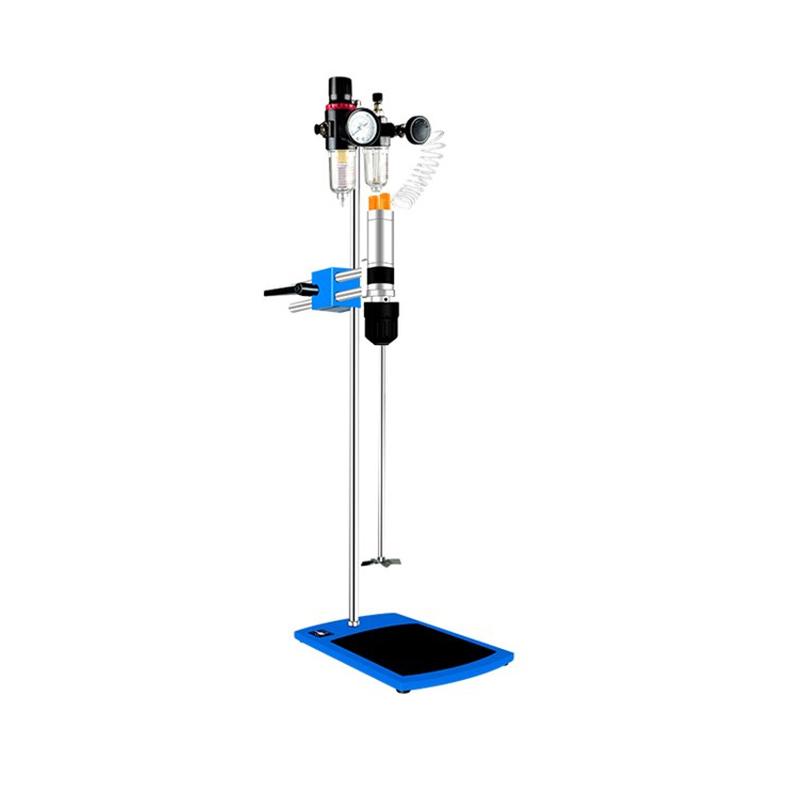

HuXi HJQ-2/20030051 Pneumatic StirrerSPEC

HuXi HJQ-2/20030051 Pneumatic StirrerDetails

HuXi HJQ-2/20030051 Pneumatic StirrerPacking list

- SKU

- NB037855

- Torque

- ≤80N.cm

- Motor power

- 150w

- ventilation pressure

- 0~6bar

- processing viscosity

- ≤5000cp

- Speed range

- 3000rpm

- Rotational torque

- ≤80N.cm

- Impeller fixing method

- Self-locking chuck

- Processing method

- batch processing

- Ambient Temperature

- 5~40℃

- Allowable Relative Humidity

- 80%

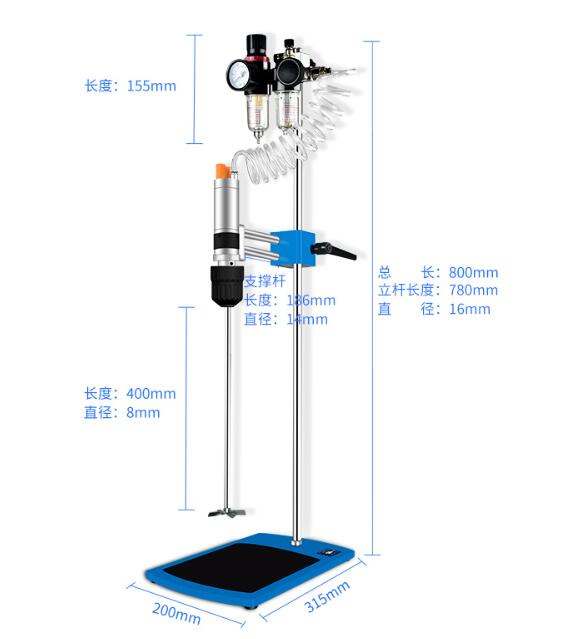

- Instrument size

- 315*200*800mm

- Packaging Dimensions

- 825*365*1200mm

- Net Weight

- 9.5kg

- Gross Weight

- 11.5kg

- Impeller type

- Dissolving Impeller

- Impeller diameter

- 30mm

- Impeller rod diameter

- 8mm

- Impeller rod length

- 350mm

Applications

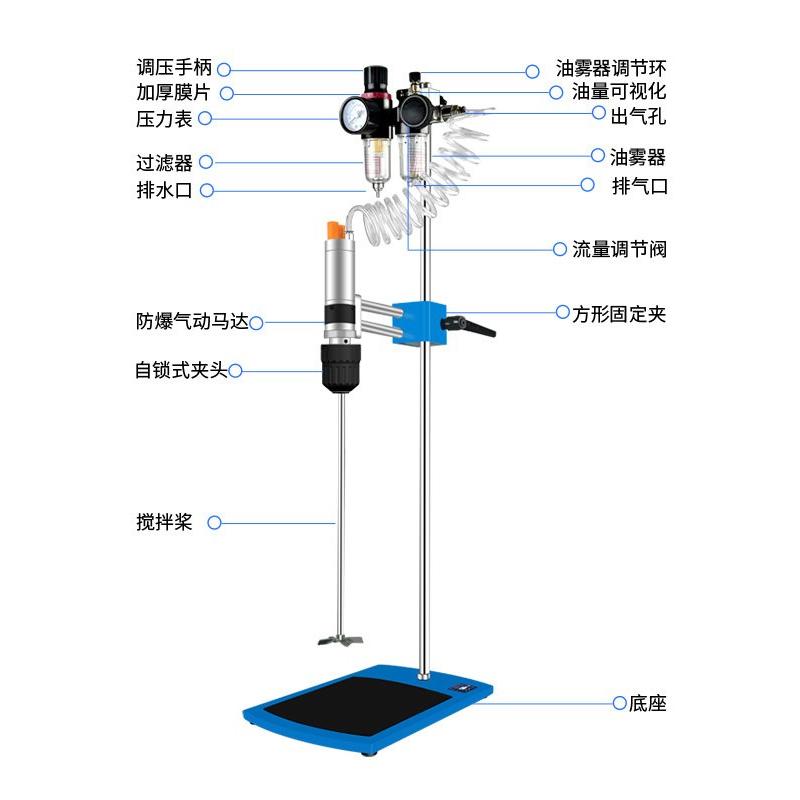

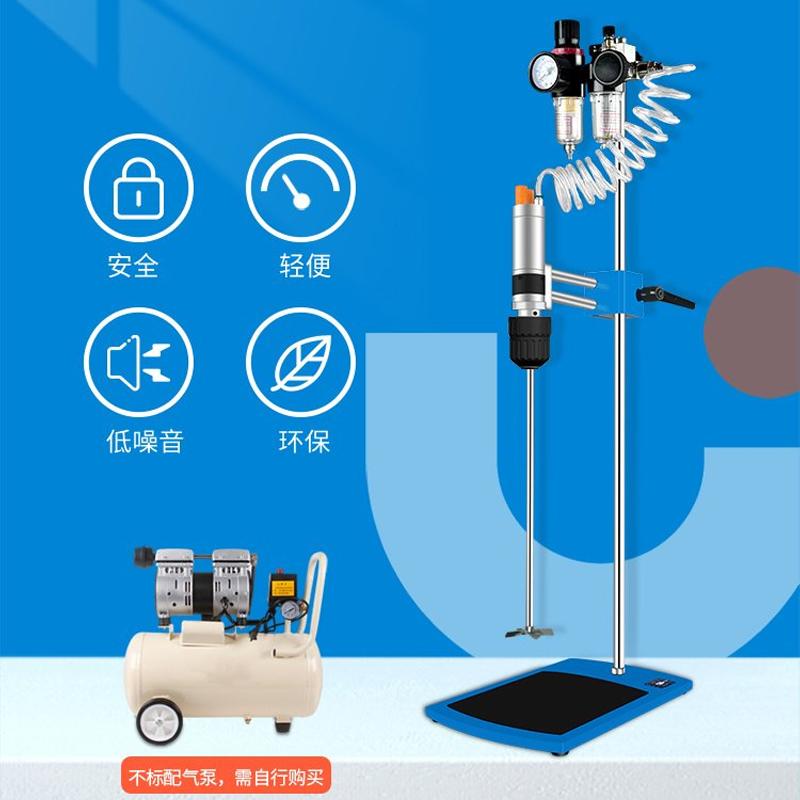

HJQ-2 Pneumatic Mixer is a power device that utilizes a good air motor, uses compressed air as the driving force of the working medium, and uses the expansion of the compressed gas to convert the pressure energy into mechanical energy, so as to realize the stirring and mixing of samples in the experimental environment, etc., especially suitable for belt Stirring of flammable and explosive substances or paints, chemicals, solvents, etc. in high-temperature environments.

Features

Small size, high power, safe and light operation;

With high rotational torque, it can start with load;

Standard pressure gauge, you can check the pressure value at any time;

Imported self-locking chuck with self-locking function, high concentricity and long life;

The square lifting clamp adopts double hole mode, the height can be adjusted arbitrarily, and the clamping is firm, making the operation more stable;

The whole machine adopts an explosion-proof, non-sparking, good air motor that can not afford static electricity, which is safe in operation and not easily affected by external environmental factors;

A variety of stirring paddles are available.

Product Dimensions

optional paddle

1. Round three-hole fan-type stirring impeller

Application: Stirring performance is mild, used at medium and low speeds, and used in mediums that need to be soft and stirred.

| style | Paddle diameter mm | Rod diameter mm | Rod length mm |

| 50 | 8 | 300 |

| 50 | 8 | 400 | |

| 50 | 8 | 500 | |

| 70 | 8 | 300 | |

| 70 | 8 | 350 | |

| 100 | 10 | 300 | |

| 100 | 10 | 400 | |

| 100 | 10 | 500 |

2. Dissolving stirring paddle

Application: Application: Use at medium and high speeds to make the mixed medium flow radially from top to bottom, forming strong turbulent flow and high shear force to crush particles in the liquid, suitable for medium and high viscosity liquids.

| style | Paddle diameter mm | Rod diameter mm | Rod length mm |

| 30 | 8 | 350 |

| 40 | 8 | 350 | |

| 50 | 8 | 350 | |

| 60 | 8 | 350 | |

| 80 | 8 | 350 | |

| 100 | 8 | 350 | |

| 120 | 8 | 350 | |

| 150 | 8 | 350 |

3. Three-blade stirring paddle

Application: Made of stainless steel, the mixed medium flows axially from top to bottom to generate local shear force, and can be used at medium and high speeds.

| style | Paddle width mm | Paddle height mm | Rod diameter mm | Rod length mm |

| 70 | 1.5 | 6 | 300 |

| 70 | 1.5 | 6 | 350 | |

| 70 | 1.8 | 6 | 300 | |

| 70 | 1.8 | 6 | 350 | |

| 70 | 1.5 | 8 | 300 | |

| 70 | 1.5 | 8 | 350 | |

| 70 | 1.8 | 8 | 300 | |

| 70 | 1.8 | 8 | 350 |

4. Centrifugal stirring paddle

Application: Foldable stirring paddle, the two blades expand with the increase of speed, used at medium and high speeds, suitable for narrow-mouth containers with a paddle height of 10mm.

| style | Paddle diameter mm | Rod diameter mm | Rod length mm |

| 90 | 8 | 300 |

| 90 | 8 | 350 | |

| 90 | 8 | 400 | |

| 90 | 8 | 500 | |

| 90 | 10 | 300 | |

| 90 | 10 | 400 | |

| 90 | 10 | 500 | |

| 90 | 10 | 650 |

5. Four-blade stirring paddle

Application: standard stirring impeller, made of stainless steel, used in medium and high speed, suitable for medium and low viscosity.

| style | Paddle diameter mm | Rod diameter mm | Rod length mm |

| 50 | 8 | 300 |

| 50 | 8 | 400 | |

| 50 | 8 | 350 | |

| 50 | 8 | 500 | |

| 100 | 10 | 300 | |

| 100 | 10 | 400 | |

| 100 | 10 | 500 |

6. Screw type stirring paddle

Application: Slow-speed stirring impeller, often operated in the laminar flow area, the liquid rises or falls along the helical surface to form an axial up and down circulation, suitable for mixing and heat transfer of medium and high viscosity liquids.

| style | Paddle diameter mm | Rod diameter mm | Rod length mm |

| 50 | 8 | 350 |

| 60 | 8 | 350 | |

| 70 | 8 | 350 | |

| 80 | 8 | 350 | |

| 90 | 8 | 350 | |

| 100 | 8 | 350 |

7. Round six-hole fan-type stirring impeller

Application: Tangential flow is generated when stirring, small turbulent flow, good heat exchange performance, mild stirring performance, and medium and low speed use.

| style | Paddle diameter mm | Rod diameter mm | Rod length mm |

| 50 | 8 | 300 |

| 50 | 8 | 400 | |

| 50 | 8 | 350 | |

| 50 | 8 | 500 | |

| 100 | 10 | 300 | |

| 100 | 10 | 350 | |

| 100 | 10 | 400 | |

| 100 | 10 | 500 |

8. One-word stirring paddle

Application: Stainless steel material, medium and high speed use, suitable for medium and low viscosity mixing.

| style | Paddle diameter mm | Rod diameter mm | Rod length mm |

| 50 | 8 | 300 |

| 50 | 8 | 400 | |

| 50 | 8 | 500 | |

| 60 | 8 | 300 | |

| 60 | 8 | 350 |

9. Round anchor stirring paddle

Application: Tangential flow is generated when stirring, and high shear rate is formed at the edge, so that the mixed medium is not easy to deposit on the container wall, and it is suitable for low speed.

| style | Paddle width mm | Paddle height mm | Rod diameter mm | Rod length mm |

| 100 | 60 | 8 | 300 |

| 100 | 60 | 8 | 350 |

10. Square anchor stirring paddle

Application: Use at low speed, generate tangential flow, and form high shear rate at the edge, so that the mixed medium is not easy to deposit on the container wall. It is suitable for polymer reaction and dispersion of minerals in liquid. It is a satisfactory stirring element for medium and high viscosity fluids.

| style | Paddle width mm | Rod diameter mm | Rod length mm |

| 70 | 8 | 300 |

| 70 | 8 | 350 | |

| 70 | 8 | 500 | |

| 90 | 10 | 650 | |

| 140 | 10 | 800 |

11. Square hole fan type stirring impeller

Application: Stainless steel material, used at medium and low speeds

| style | Paddle width mm | Rod diameter mm | Rod length mm |

| 50 | 8 | 350 |

| 60 | 8 | 350 | |

| 60 | 8 | 350 | |

| 70 | 8 | 350 |

HJQ-2/20030051

HJQ-2/20030051