Pushen KTQ-150mm Micrometer Film Applicator Spreader width 150mm

SEPushen KTQ-150mm MicroMeter Film ApplicatorSPEC

Pushen KTQ-150mm MicroMeter Film ApplicatorDetails

Pushen KTQ-150mm MicroMeter Film ApplicatorPacking list

- SKU

- NB038341

- type

- Adjustable

- WFT

- 0 ~ 3500µm

- Application width

- 150mm

- precision

- ± 2μm

- material

- Aluminum oxidation

- Graduation

- 10µm

Introduction

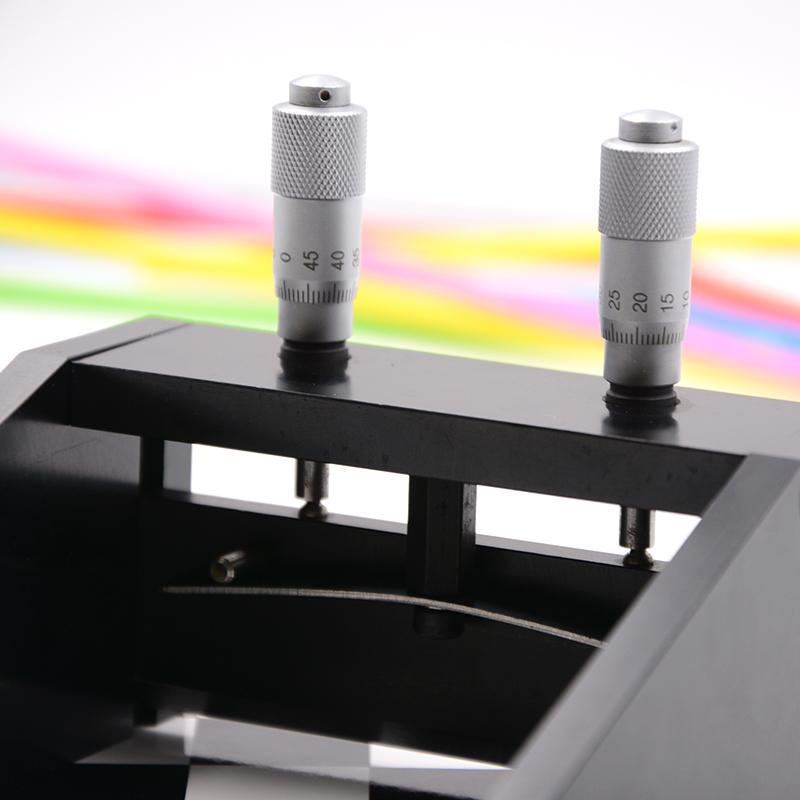

There are two differentiators on the upper end of the Pushen KTQ-II adjustable Film Applicator , and the scraper can be adjusted by rotating the differentiator to control the gap to apply a wet film of a specific thickness. KTQ-II/25204 adjustable Film Applicator is suitable for coating flat substrates, as well as high-viscosity and high-concentration coatings, with uniform coating. The film width of KTQ-II adjustable Film Applicator is 150mm, and the precision is ±2μm.

Features

1. KTQ-II/25203 adjustable Film Applicator can be used to coat uniform wet film thickness on flat substrates.

2. The coating thickness range of the adjustable Film Applicator is 0~3500μm, and the division value is 10μm.

3. The pushen adjustable Film Applicator has an extended side, which can draw the paint during the film coating process, and is suitable for high viscosity and high concentration paint film.

operation method

First, place the KTQ-II/25204 adjustable Film Applicator on a flat test substrate surface and adjust the scraper to the required gap (approximately twice the desired wet film thickness)

Second, pour a small amount of test sample between the end plates at a slow and uniform speed (1~2cm/s) at the front of the coating knife of the adjustable Film Applicator.

Third, move the KTQ-II/25203 Adjustable Film Applicator until the paint is fully applied and any remaining paint has been removed from the end of the film path.

Fourth, the actual applied wet film should be measured using a wet Film Thickness Gauge and the gap adjusted until the desired wet film thickness is achieved.

NOTE: The exact ratio of wet film thickness to any applicator knife gap depends on the materials used, the viscosity and texture of the liquid, the force exerted on the applicator knife, the film speed, and the geometry of the film edge.

maintenance measures

1. The KTQ-II/25204 adjustable Film Applicator should be cleaned and dried with an appropriate solvent immediately after use.

2. The two ends of the scraper move in the groove, and the groove needs to be kept free of test sample material at all times.

3. The differentiators require occasional repositioning to correct for wear or misalignment. Adjustments are made by loosening, rather than removing, two concealed set screws on each differentiator, allowing the assembly to be lowered or raised.

KTQ-150mm

KTQ-150mm