MODERNER HBM-0.5L Laboratory horizontal sand mill Coating inks Dispersion

Moderner HBM-0.5L Laboratory horizontal sand millSPEC

Moderner HBM-0.5L Laboratory horizontal sand millDetails

Moderner HBM-0.5L Laboratory horizontal sand millPacking list

- SKU

- NB038427

- Motor power

- 750W

- Rotation speed

- 150-3000rpm

- Sand cylinder Volume

- 0.5L

- Sand cylinder void Volume

- 0.4L

- Discharge filter plate gap

- 0.5mm

- Zircon bead diameter is recommended.

- 1.4~1.6mm

- Power Supply

- 220V 50/60Hz

Overview

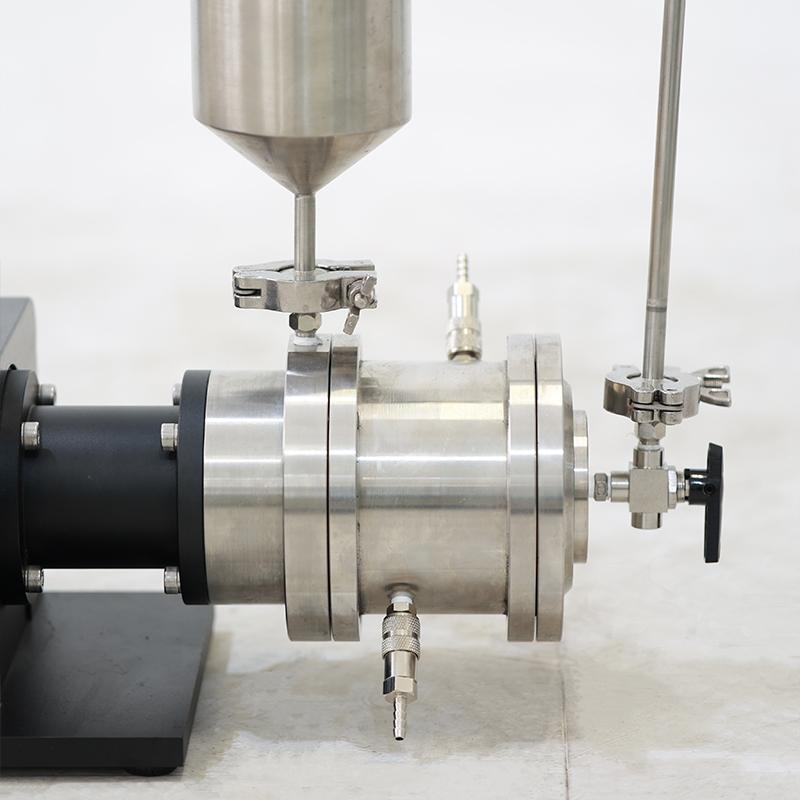

The HBM-0.5L laboratory horizontal sand mill adopts the horizontal sand grinding method to achieve rapid dispersion of materials through the shearing action generated by the rapid centrifugal rotation of the grinding beads. During the dispersion process, this machine can realize automatic external circulation of materials through external nozzles and feed hoppers to improve dispersion efficiency. The sanding barrel of this machine has a cooling interlayer, which can pass constant temperature water to cool the material. This machine is suitable for rapid dispersion of small quantities of samples in chemical industry laboratories such as coatings and inks.

In view of the characteristics of laboratory use that requires frequent replacement of materials, the main shaft of this machine is sealed with a lip seal, making the disassembly, assembly and cleaning of this machine relatively simple and convenient. Since lip seals are relatively more fragile than mechanical seals, this machine is not suitable for continuous production use.

Steps

Loading beads: Remove the discharge end cover (the small cover in the middle), take out the filter plate, and then load beads into the sanding barrel from the hole. After the beads are installed, turn the sanding spindle by hand to check that there is no jamming, and then install the filter plate and discharge end cover.

Adding materials: Add the wetted and pre-dispersed materials from the hopper into the sanding barrel, and then start the machine.

Ball valve: The discharge end cover is equipped with a three-way ball valve, which can be closed, discharged from the lower port, and recycled from the upper port.

Start up: Turn on the power, press the RUN button, use the speed adjustment knob to gradually increase the speed to the required speed, and sand the material. To realize automatic external circulation of materials, it is necessary to turn the three-way ball valve to the upper opening, and then increase the speed until the material is discharged from the return pipe. If the speed is too low, automatic external circulation cannot be realized.

Shut down: press the STOP button to stop the motor. It is better to develop the habit of returning the speed knob to zero and gradually increase the speed next time you turn on the machine.

Cleaning: After the work is completed, disconnect the power supply, and perform disassembly, cleaning and maintenance work in a timely manner.

HBM-0.5L

HBM-0.5L