MODERNER XD-035YJBL-A1 cathode disbonding testing machine

Moderner XD-035YJBL-A1 Cathode disbonding machineSPEC

Moderner XD-035YJBL-A1 Cathode disbonding machineDetails

Moderner XD-035YJBL-A1 Cathode disbonding machinePacking list

- SKU

- NB038430

- Interior size

- 内箱Size1±0.02m³ W725mm×H725mm×D600m

- exterior size

- W1280mm×H1400mm×D1060mm(约)

- temperature

- Temperature range: + 20 ℃~ + 50 ℃

- Instrument resolution

- Temperature: 0.1 ℃

- Temperature Fluctuation

- ±0.5℃

- Temperature Uniformity

- ≤1.5℃

- circulating temperature control medium

- 1. Water or non-corrosive fluids with viscosity < 50mPa·s at 20~90 ℃

- Blowing device

- PP tube micropore bubbling

- Thermal equilibrating method

- Electric heating, PID + SCR equilibrating control

- Temperature transducer

- PT100

- Measurement Accuracy

- 0.2%

- Control instrument

- Delta thermostat DTK series

- power regulator

- Solid State Relay SSR 40A

- PLC

- SIEMENS SMART 200

According to the requirements of the test method in the standard GB/T 7790-2008 and ISO 15711:2003 Determination of the cathodic stripping resistance of paints and varnishes exposed to sea water, we fully consult with the customer and fully understand the test process to produce Got this cathode stripping box.

This equipment exposes the prepared sample to the test solution, uses a cathodic protection circuit to control the test potential, checks the bubbles in the sample coating and the penetration under the coating through aging, and then evaluates the performance of the coating under cathodic protection conditions. .

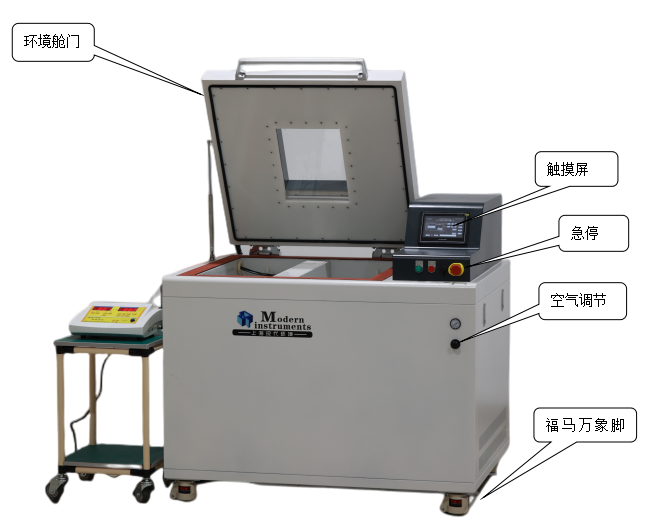

The cathode peeling test machine equipment is composed of an electrical control system, a refrigeration system, a heating system, a bubbling system, an alarm system, a human-computer interaction system, etc. The inner tank is welded with PP plate, and the outer shell is spray-painted with sheet metal.

Equipment details

Functional area introduction

| 1. Equipment requirements | |

| 1.1 Power supply | â Power supply: AC220V50Hz |

| â¡Maximum load capacity: 3KW | |

| â¢Maximum current: 10A | |

| â£Power switch capacity: 20A | |

| 1.2 Water supply | Please use pure water or distilled water, conductivity â¤10μS/cm |

| 2. Moving conditions | |

| When moving parts and components into this laboratory, please meet the conditions on the right | Height of path passage and door: more than 2200mm |

| Width of path passage and door: more than 1500mm | |

| When using an elevator; in addition to meeting the above dimensions, the following requirements must also be met | |

| Depth: more than 2300mm; load capacity: more than 1000Kg | |

| â»If you cannot meet the above conditions, please be sure to contact our company in advance. | |

- 1ASTM D1876-2023《Standard Test Method for Peel Resistance of Adhesives (T-Peel Test)》

- 2HG/T 3658-1999《Double sided pressure sensitive adhesive tapes》

- 3ISO 4628-1-2016《Paints and varnish coatings - Assessment of ageing - Quantity and size of defects and assessment of uniformly varying strength of Appearance - Part 1: General principles and assessment system》

XD-035YJBL-A1

XD-035YJBL-A1