SETCAS KW-4B Spin Coater 4A upgrade, stainless steel body domestic (CN) motor

SESetcas KW-4B Glue levelerSPEC

Setcas KW-4B Glue levelerDetails

Setcas KW-4B Glue levelerPacking list

- SKU

- NB038452

- Speed regulation range

- I file: 50~10000rpm; II file: 1000~10000rpm

- Gluing time

- I file: 0~999s; II file: 0~999s

- Suitable substrate

- Φ5~ Φ120mm silicon wafer and other materials and other homogenizers

- show

- Dual LED digital display with countdown display

- Speed stability

- ±0.5%

- Uniformity of glue

- ±1%

- Motor power

- 40W, single-phase 110-240V Power

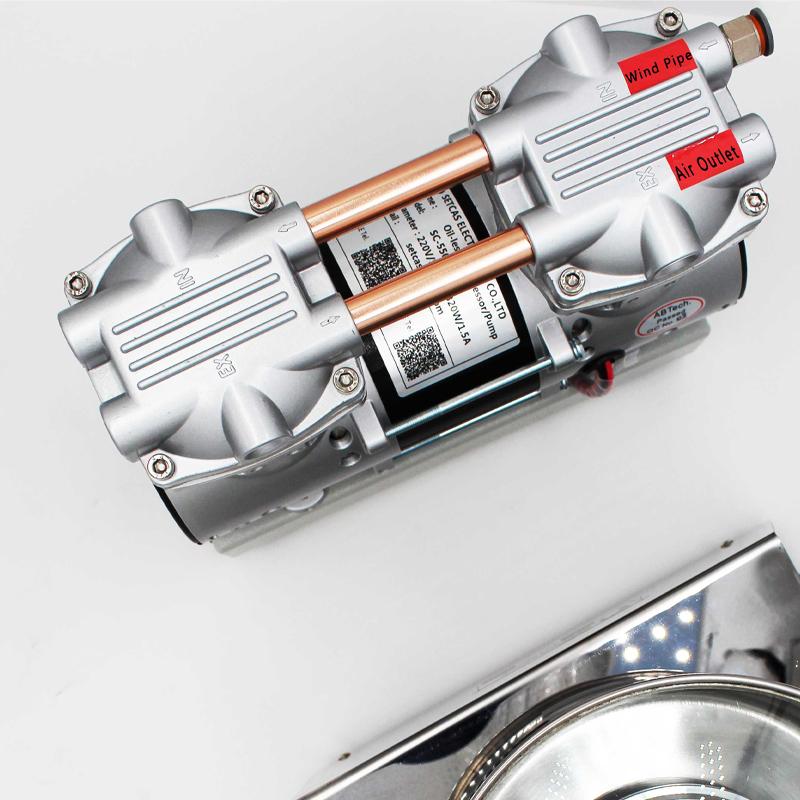

- Vacuumpump pumping rate

- ≥60L/min

- Pump Weight

- 8.5KG

- Dimensions

- 215*240*220mm

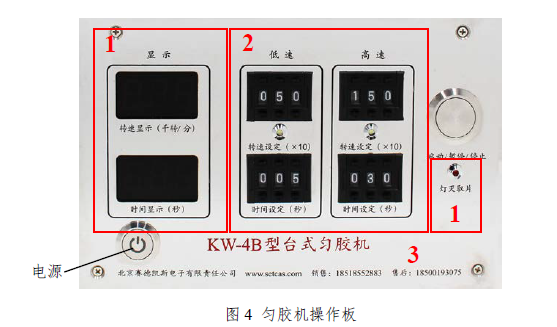

operation panel

1. Display

Speed display (thousand revolutions per minute): Display the current running speed of the motor, that is, the current speed of glue spreading;

· Time display: display the remaining time of the motor running, that is, the remaining glue time;

· Vacuum indicator: Indicates the current vacuum state and substrate adsorption status, the light is on when adsorption, and off after desorption.

2. Speed

Low gear

Speed setting (×10): the running speed setting of the low-speed motor, that is, the actual set speed is: set the number X10;

· Time setting (seconds): The running time setting of the low-speed section with the glue-spraying speed set, that is, the glue-spraying time setting of the low-speed section.

High gear

Speed setting (×10): the running speed setting of the motor in the high-speed section, that is, the actual set speed is: set the number X10;

· Time setting (seconds): The running time setting of the glue spreading speed set in the high speed section, that is, the glue spreading time setting in the high speed section.

3. Button

· Power supply: control the circuit on and off of the whole glue homogenizer;

· Start/Pause/Stop

a. Start: Click (short press) to control the machine to start;

b. Pause: In the starting state, after pressing the button, the motor pauses, and then press the button to resume the motor (the motor speed and remaining glue time remain unchanged);

c. Stop: long press the button for more than 2 seconds, the motor stops;

Operating procedures

Uniform glue operation process

After the installation and general connection of the mechanical pump and glue homogenizer are completed, the glue homogenization operation can be carried out. The specific steps are as follows:

1. Turn on the power: turn on the power switch of the glue homogenizer and the oil-free pump in turn;

2. Check: After step 1 is completed, the power light and the LED lights in the display column are on, indicating that it can be used normally;

3. Setting parameters: Set the appropriate parameters (glue speed, time) through the operation panel of the glue homogenizer;

4. Putting the film: place the substrate to be evenly glued on the film holder, as shown in Figure 5;

5. Suction sheet: Press the start/pause/stop button twice quickly, the vacuum indicator light is on, and the substrate is adsorbed on the sheet holder;

6. Close the cover: cover the cover of the homogenizer;

7. Start the motor: press the start/pause/stop button (1 time), the motor starts and runs according to the parameter setting requirements, first in low gear , then in high gear;

8. Epoxy:

· Static Epoxy

If glue dispensing is required in a static state, the operation should .

· Low speed dispensing

If dispensing at low speed is required, this operation should be done in step 7.

9. Take the film:

· Process take film

If you need to take and put slices during a glue leveling process, you can press and hold the start/pause/stop button (more than 2 seconds) to end the glue leveling process. After the motor stops rotating, the air circuit will be automatically cut off before proceeding. Take and put film operation.

· Terminate fetching

If it is necessary to take and put the film after the end of a uniform glue process, you only need to wait for the process to end and the motor to stop rotating , then automatically cut off the air circuit to carry out the film take and put operation.

KW series homogenizer model comparison

- 1Two different spin coating methods: dynamic dispensing and static dispensing

- 2What are the special requirements for spin-coated nanoparticles?

- 3Four key stages of spin coating

- 4Spin coatings spin coaters: principles, applications, functions and maintenance

- 5Common defects in spin coating of homogenizer

- 6Spin Coater selection and classification: a one-stop guide

- 7What are the common problems of spin coating experiment?

- 8What is spin coating and how does it work?

- 9Three small suggestions for improving the effect of spin coating

- 10Spin-on cleaning and specific cleaning steps

KW-4B

KW-4B