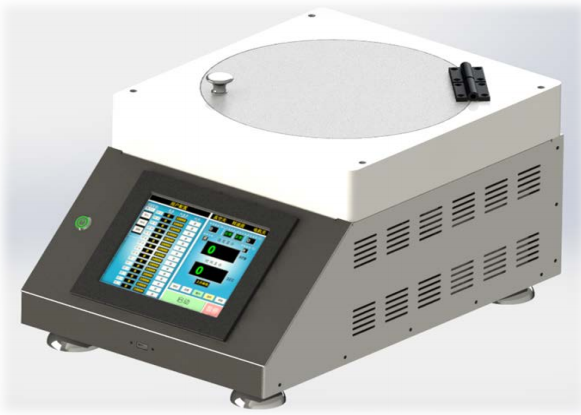

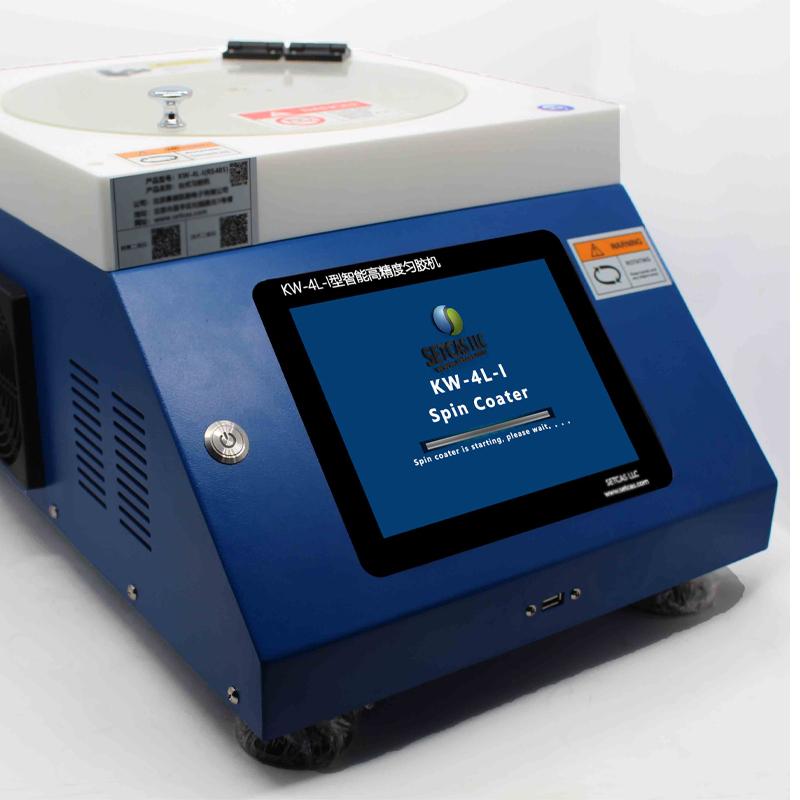

SETCAS KW-4L-I automatic glue dispenser, high-end

SEMaximum support 8 inches, touch screen with program control, polytetrafluoroethylene (PTFE) cavity, integrated automatic glue function, maximum speed 12000rpm, with external foot switch

Price: Please contact customer service

Model:

Setcas KW-4L-I Glue levelerSPEC

Setcas KW-4L-I Glue levelerDetails

Setcas KW-4L-I Glue levelerPacking list

- SKU

- NB038458

- Suitable substrate

- 5~200mm

- Speed range

- 1~12000rpm

- Speed Accuracy

- 1rpm

- Speed stability

- ±0.1%

- Acceleration range

- 1~10000rpm/s

- glue uniformity

- ±1%

- Control signal

- indicator

- Human Machine Interface

- 8 inch touch screen

- Communication interface

- USB (std.)/RS485 (std.)

- stylus

- BAMBOO Resistance Pen (std.)

- Vacuumpump

- AP-550V No oil pump

- Set data

- Unlimited sets of data, 15 revolutions per set (std.)

- Every time

- 0~10000s

- Store data

- Unlimited set of data

- Data Protection

- Default with power-down protection function

- Swirl/spin direction

- Can be reversed

- AC Power port of glue leveler

- AC100-250V

- Vacuumpump Power interface

- AC220V (std.)

- Gluer power

- 650W

- Vacuumpump power

- 350W

- Vacuumpump pumping rate

- ≥60L/min

- Volume of homogenizer

- 340*500*250mm

- Gluer Weight

- 18KG

- Pump Weight

- 9KG

- Environment temperature

- 0~40℃

- Relative Humidity

- <85%

KW-4L-I

Glue leveler

Maximum support 8 inches, touch screen with program control, polytetrafluoroethylene (PTFE) cavity, integrated automatic glue function, maximum speed 12000rpm, with external foot switch

feature of product

With automatic dispensing function, peripheral foot switch;

PTFE polymer chamber material, acid and alkali resistance, corrosion resistance, with a curved chamber bottom to facilitate glue export;

It has the function of exhaust gas pumping and exhausting in the chamber;

It can be heated and baked by gas, the temperature range: 0-200℃, the heating and cooling speed is 100℃/S; the direction of forward and reverse spin coating can be switched freely;

Real-time display of speed rise curve;

It has the functions of motor glue feeding alarm and protection;

It has alarm and interlock functions for insufficient substrate adsorption force.

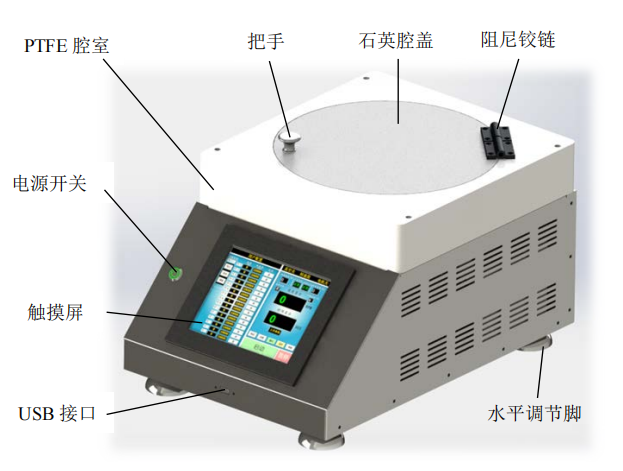

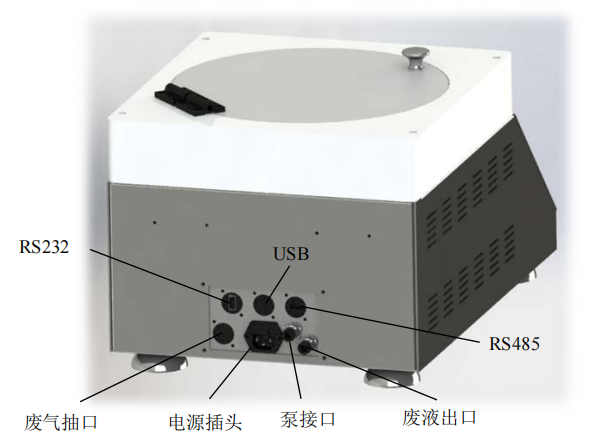

Product Structure

Function introduction of KW-4L-I front left view angle

Function introduction of KW-4L-I rear right view angle

KW series homogenizer model comparison

FAQ

QThe platinum-iridium alloy sheet is relatively thin. Isn't our fixing method vacuum adsorption? I think the vacuum hole is in the middle. When sucking like this, it may cause the platinum-iridium alloy sheet to deform. Can you make more vacuum holes and spread them around, so that the platinum-iridium alloy sheet can be evenly stressed?

A

This thing is not biased, there are many kinds, according to the size of your sample to match, you said that the hole is the smallest five millimeters or ten millimeters, its adsorption sample is relatively small, so it can only have one hole, there is also that kind, that is, the different kind of concentric circles have a lot of sticking out.

QWhat are the benefits of reserving a leakage port at the bottom?

A

The waste liquid can be collected without cleaning, or it can be recycled twice.

QAutomatic glue addition, do not remotely do this? The amount of automatic glue dripping each time can also be set, right?

A

KW-4L-I is OK, but there is no heating function. You can set the number of drops each time.

Knowledge

- 1Detailed operation steps schematic diagram of the glue leveler

- 2What is spin coating?

- 3Spin coatings spin coaters: principles, applications, functions and maintenance

- 4What is spin coating and how does it work?

- 5Three small suggestions for improving the effect of spin coating

- 6Two different spin coating methods: dynamic dispensing and static dispensing

- 7What are the common problems of spin coating experiment?

- 8Spin-on cleaning and specific cleaning steps

- 9What are the special requirements for spin-coated nanoparticles?

- 10Common defects in spin coating of homogenizer

Standard

KW-4L-I

KW-4L-I