SETCAS setcas KW-AG-II automatic glue dispenser 0.1-5000 μl

Setcas KW-AG-II Epoxy machineSPEC

Setcas KW-AG-II Epoxy machineDetails

Setcas KW-AG-II Epoxy machinePacking list

- SKU

- NB038472

- Epoxy range

- 0.1-5000μl

- Epoxy Repeatability

- ≤±0.01%

- Epoxy method

- 16 kinds (with glue time display)

- setting method

- Numeric buttons make the set range clear at a glance

- Epoxy interval

- 0.1-9 (when automatically dispensing glue)

- Epoxy Timer

- 00.01-99.99S

- Input air pressure

- 10-100PSI

- Instrument size

- 120mm(W)X150mm(D)X320mm(H)

- Weight

- 3KG

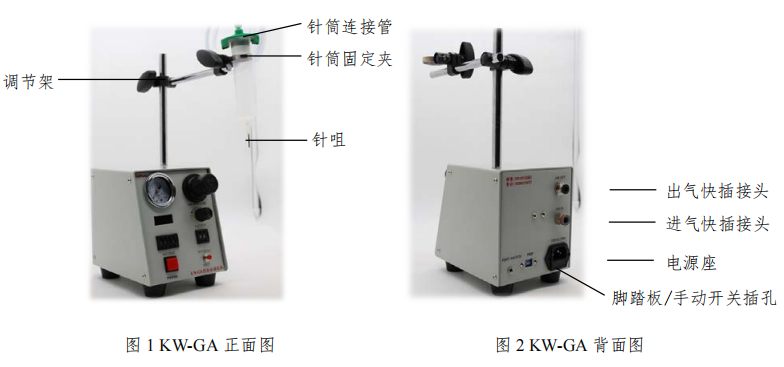

Product Structure

Usage environment

· The product Operating Environment requires cleanliness and low humidity (temperature 0-40℃, humidity <85%);

· The product is connected to high-Voltage electricity, please disconnect the power supply before maintenance;

· The glue used may be toxic and flammable, please handle and operate according to relevant requirements.

installation method

After the equipment is installed, glue can be dispensed according to the following steps:

1) Syringe installation: Select the appropriate needle tip and install it on the syringe;

2) Liquid material injection: refer to Figure 8 and the corresponding liquid material injection instructions;

3) Debugging

a) Discharging mode: Set the discharging mode encoder to F1;

b) Power connection: Turn on the power switch to turn on the host;

c) Air pressure adjustment: Adjust the air pressure regulator so that the air pressure is 25 psi as the initial calibration test;

d) Press "SHOT" until the liquid material is spit out evenly and the machine works normally;

e) Dropping point volume adjustment: adjust the discharge time dial key, air pressure regulator and needle thickness to obtain the appropriate liquid discharge volume, except for F1 discharge mode;

f) Vacuum pullback force: Adjust the vacuum controller so that no droplets will seep out when the liquid material is spit out;

g) Automatic timing: If automatic Timer Control is required, it can be achieved , except for the F1 spitting mode;

4) Epoxy glue

KW-AG-II

KW-AG-II