QIWEI JFS-750B Frequency Converter Disperser 750W/2800rpm Automatic Lift

SEQiWei JFS-750B (automatic lift) Frequency Converter DisperserSPEC

QiWei JFS-750B (automatic lift) Frequency Converter DisperserDetails

QiWei JFS-750B (automatic lift) Frequency Converter DisperserPacking list

- SKU

- NB038535

- Power

- 750W

- Speed regulation range

- 0~2800rpm

- Impeller diameter

- Φ50/60mm

- Grinding disk diameter

- Φ60mm

- Lifting stroke

- 250mm

- Dimensions

- 460*420*750mm

- Barrel

- 1.5L

- Power

- 220V 50HZ

- Gross Weight

- About 40KG

- Lifting method

- Automatic lift

JFS-750B variable frequency dispersing machine is an experimental equipment that integrates mixing, sanding, dispersing and other multi-functional purposes. This equipment uses Minbu motor, which has the advantages of small size, low noise, no mechanical wear of carbon brushes, and environmental protection. It directly displays the working speed when working through the frequency conversion controller.

structure

ã1. This machine adopts a double-axis constant force lifting system, which is convenient for lifting and lowering.

ã2. The dispersing disc and sanding disc are directly connected to the rotating shaft with screws.

ã3. The barrel is fixed by the left and right clamps, and the barrel adopts a jacket structure.

Install

ã1. Install the two clampers on the fixed frame respectively, with the clamping rod facing upward.

ã2. Fix the barrel in the holder, and match the barrel cover hole with the motor shaft.

ã3. Adjust the motor locking bolt to adjust the height position of the rotating shaft and the content of the container.

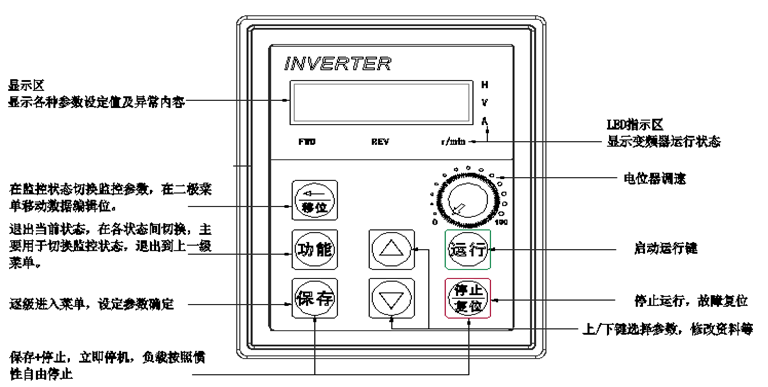

Operation guide

1. Plug in the power supply and the meter will display "0000".

2. Turn the potentiometer knob to the full left. Press the "Run" button to start the job.

3. "â³" on the control box is the ascending button, and "â½" is the descending button. During the ascending and descending process, hold down the button and do not release it, and the motor will move up and down.

4. Press the "Stop" button to stop the motor.

5. Cut off the power and shut down the machine

Series model

| model | JFS-400 | JFS-550B | JFS-750B |

| power | 400W | 550W | 750W |

| Adjustment range | 0-2800r/min | ||

| Dispersion disk | ï¿ 50mm; ï¿ 60mm; | ||

| sanding disc | ï¿ 60mm; | ||

| Lifting stroke | 250mm | ||

| Dimensions | 460Ã420Ã750mm | ||

| bucket | 1.5L | ||

| Voltage | 220V 50HZ | ||

| gross weight | About 40KG | ||

JFS-750B (automatic lift)

JFS-750B (automatic lift)