TBJ-X5-DJ1 bar Vacuum chuck Film Applicator with UV light curing + low temperature refrigeration

SECustomized, UV curing device, low temperature refrigeration device, 300mm width bar film, with Vacuum chuck, 300 * 400mmUV curing, UV main peak wave 365nm, UV Power 400 * 2W

$5553.00/set

PromotionLoading...

Coupon

Model:

zy

Manufacturer authorization

Similar products

-

CHINA UV curing Film Applicator metering rod & drawdown blade Heating type Film Applicator TBJ-B4-UV1$ 4457.00SE

CHINA UV curing Film Applicator metering rod & drawdown blade Heating type Film Applicator TBJ-B4-UV1$ 4457.00SE -

HUINUO TM1200 Wire Bar film Coater with Vacuum Table$ 2734.00SE

HUINUO TM1200 Wire Bar film Coater with Vacuum Table$ 2734.00SE -

China TBJ-X4-DJ5 bar Heating Vacuum chuck Film Applicator with UV light curing Glue Coater$ 5788.00SE

China TBJ-X4-DJ5 bar Heating Vacuum chuck Film Applicator with UV light curing Glue Coater$ 5788.00SE -

China hot-melt adhesive Drawdown blade Coater Small Glue Coater TBJ-GDHO Vacuum chuck$ 3266.00SE

China hot-melt adhesive Drawdown blade Coater Small Glue Coater TBJ-GDHO Vacuum chuck$ 3266.00SE -

CHINA TBJ-A3-DJ10 wire rod vacuum adsorption Coater automatic Film Applicator coating size 300 * 500mm$ 3987.00SE

CHINA TBJ-A3-DJ10 wire rod vacuum adsorption Coater automatic Film Applicator coating size 300 * 500mm$ 3987.00SE

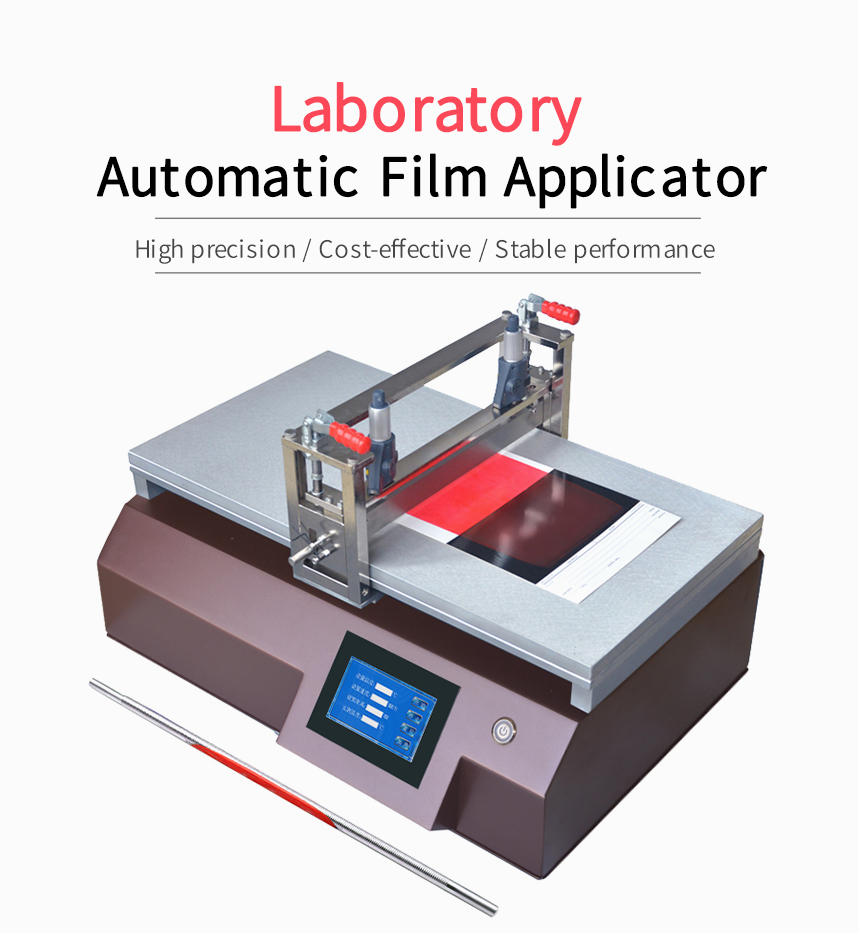

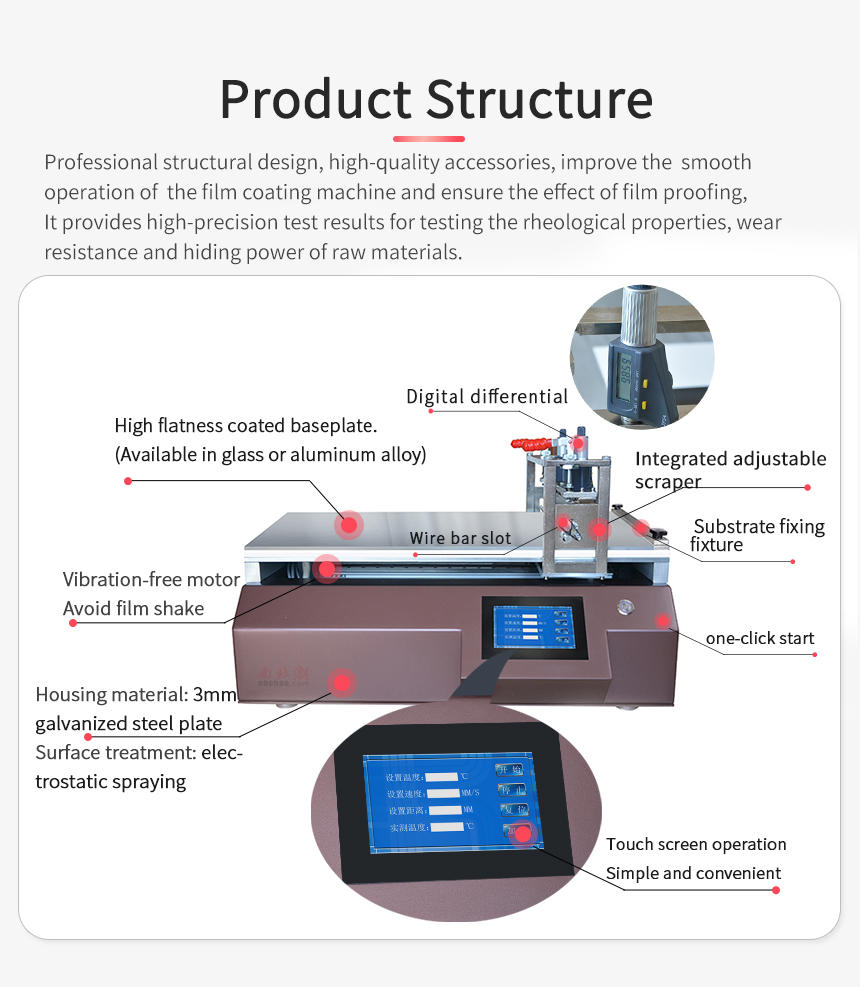

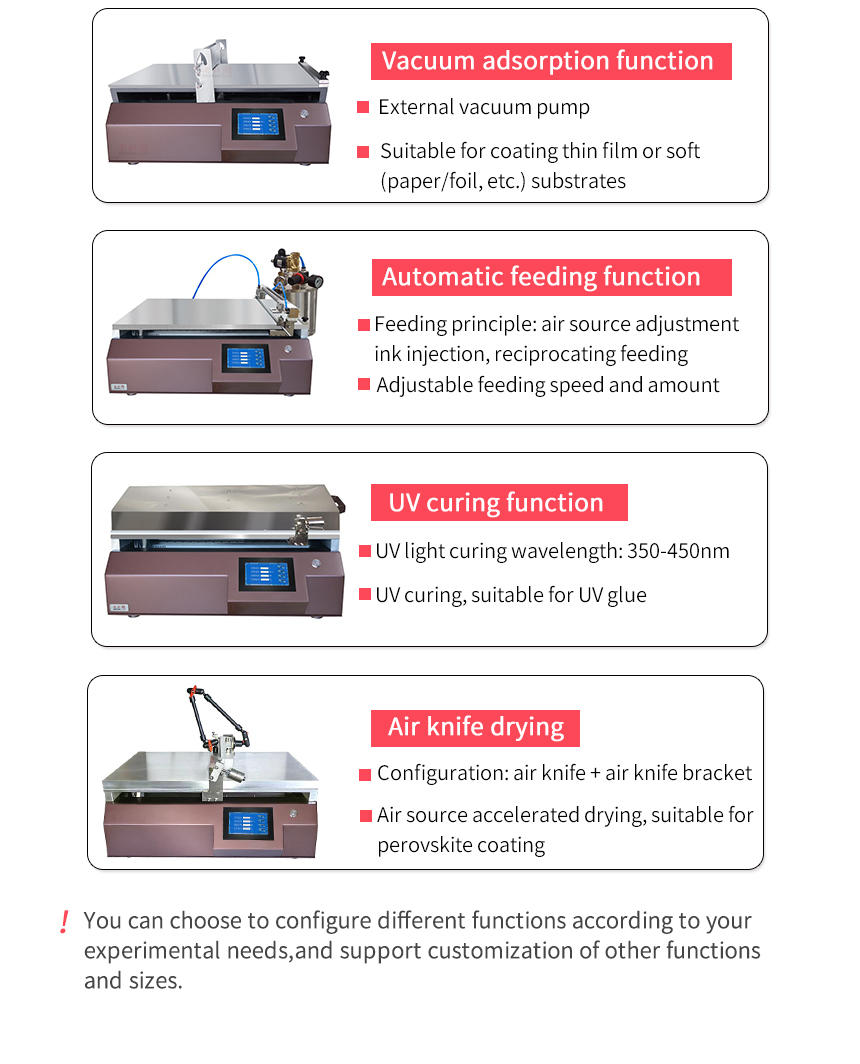

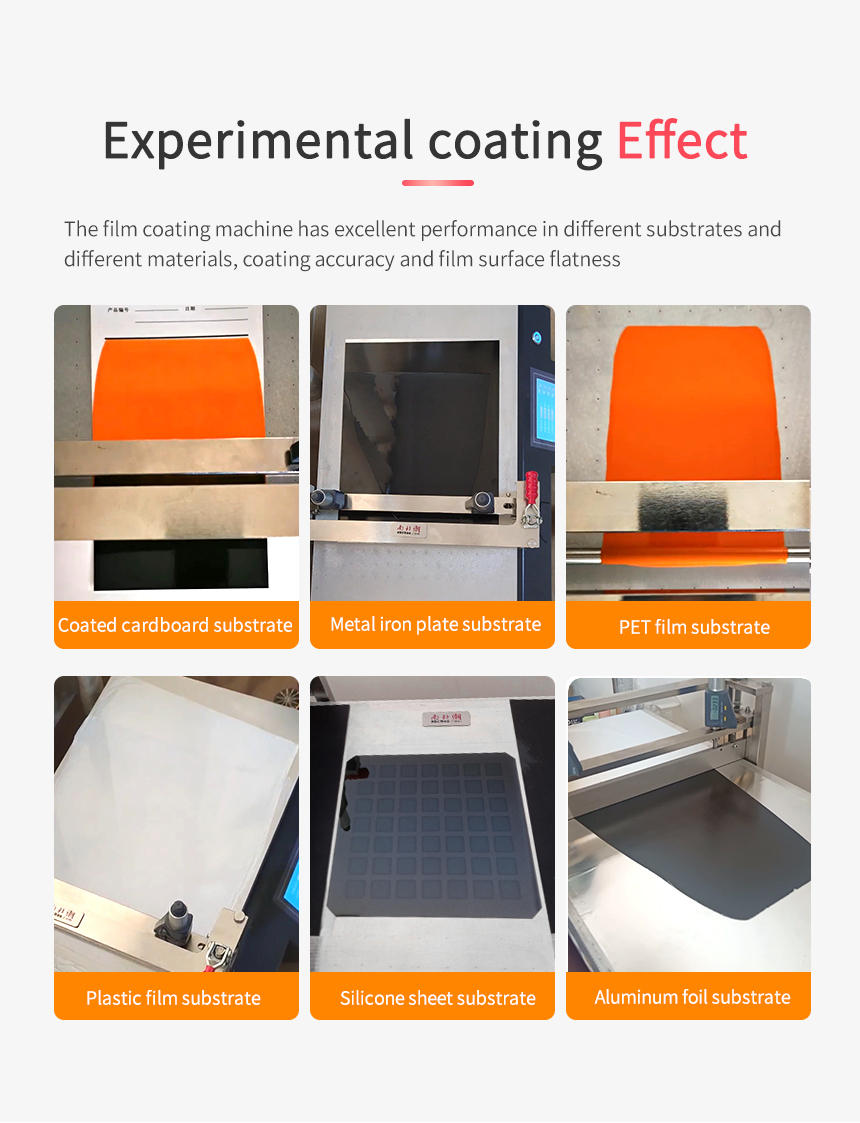

zy TBJ-X5-DJ1 Automatic Film ApplicatorSPEC

zy TBJ-X5-DJ1 Automatic Film ApplicatorDetails

zy TBJ-X5-DJ1 Automatic Film ApplicatorPacking list

- SKU

- NB038736

- Coating method

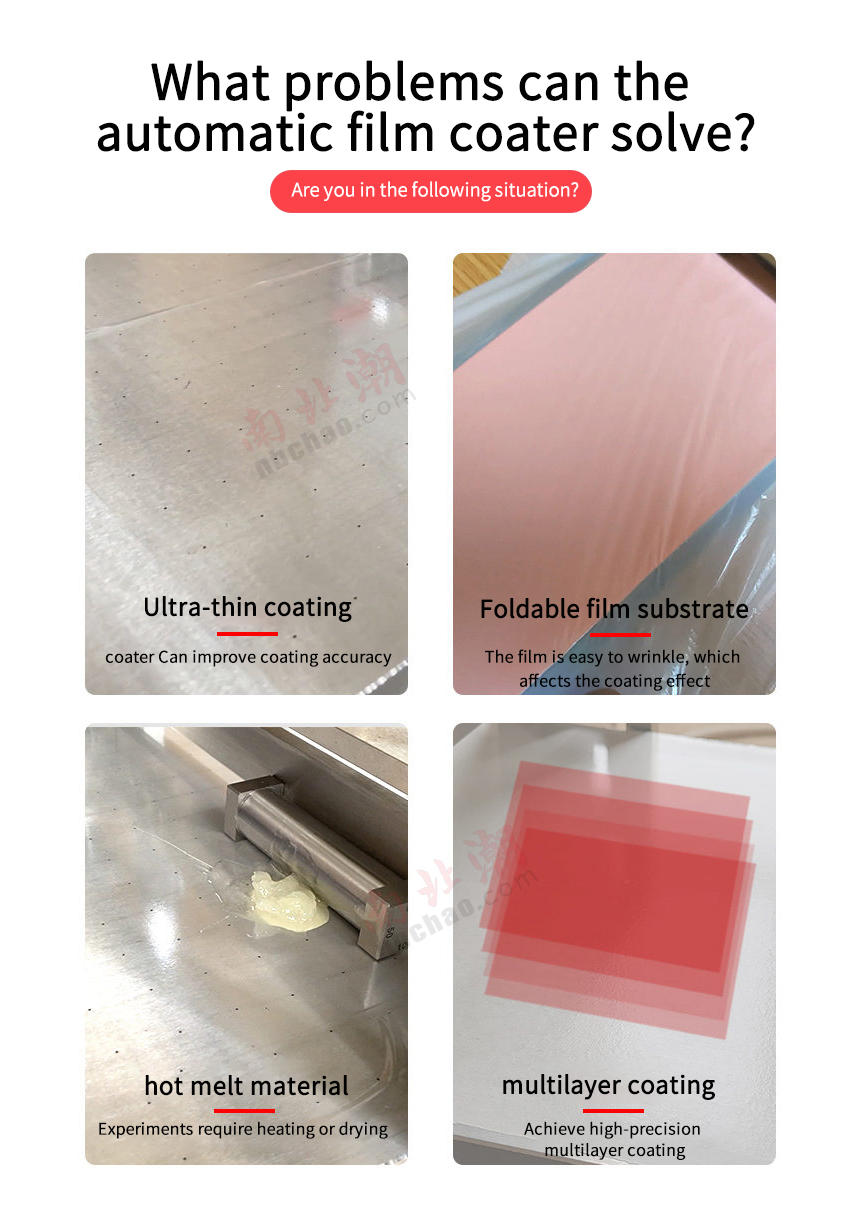

- Bar + UV curing + cryogenic refrigeration

- Mayer Rod Thickness Range

- 1-571.5 μm (Spreader thickness according to bar model)

- Mayer Rod Accuracy

- ±0.001mm

- Coating speed

- 5-200Mm/s (< 5mm/s can be customized)

- Coating size

- 300 * 400Mm (Miscellaneous size can be customized)

- Spreader distance control

- The number can be set arbitrarily within the range of 1-400mm

- Vacuum Area

- 300*400mm

- Temperature range of refrigeration

- -15℃~RT

- Temperature Accuracy

- ±3℃

- vacuum aperture

- Φ1.2mm

- Vacuum hole spacing

- 20*20mm

- Vacuum pump size

- 380*180*280mm

- Substrate clamping method

- Vacuum adsorption

- Control mode

- Touch screen control

- Host Power Supply

- Voltage 220V 50HZ

- Dimension

- 630*410*520mm

- Net Weight

- 65KG

- speed control

- Infinitely variable speed

- Bottom plate material

- aluminum alloy

- UV curing area

- 300*400mm

- UV light main peak wave

- 365nm

- UV Light Power

- 400*2W

- UV light curing wavelength

- 350-450nm

- UV UV Lamp Spacing

- 18*18mm

- Optional Accessories

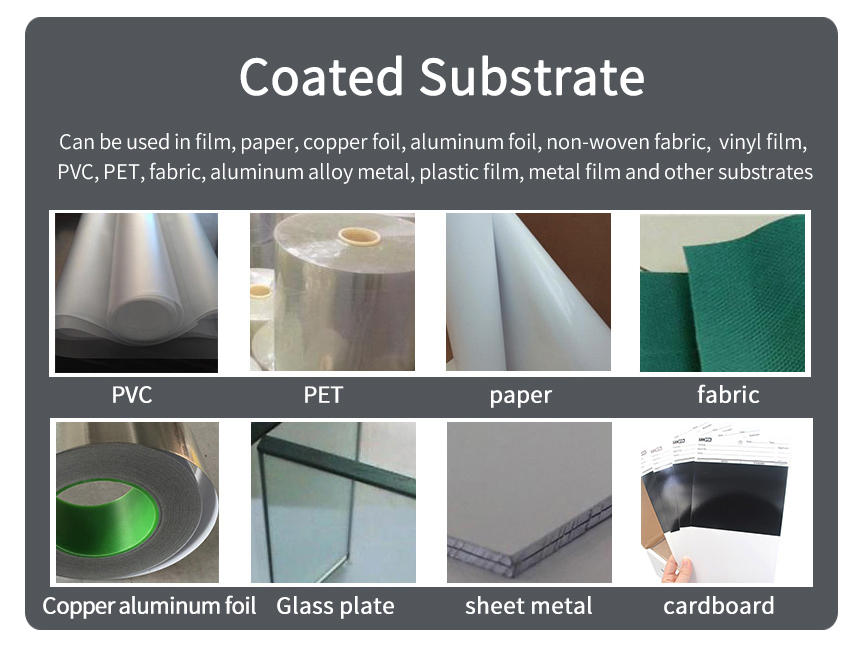

- Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle

- customizable function

- Automatic lame plating device, automatic inking system, air knife drying, remote control, upper infrared heating, double extrusion Spreader

FAQ

QSample substrate: biological raw materials, such as pig intestines, with uneven surfaces (several hundred microns);

Coating thickness: 30~ 50μm;

Material: Low viscosity, similar to water.

Refrigeration should be -10 degrees;

Biosubstrate modified films for medical apparatus

Material has no resilience;

Part of the coating is to penetrate;

The first step is to apply

The second part is frozen

The third part is lyophilized

A

Need to be customized

wire rod + vacuum adsorption + low temperature refrigeration -10 degree function + silicone pad + customized 4-sided fixture (fixture on both sides of the side)

Knowledge

- 1Application of Vacuum adsorption Spreader Technique in Preparative Fluorescence Film on Release Membrane

- 2Experimental application of water-based paints on film laminating paper by laboratory coater

- 3Experimental film coating machine case | Scrape coating slurry on release film

- 4Application of Film Applicator in Silver Nanowire film

- 5Application of Film Applicator in medicinal film

- 6Film Applicator in Nitrocellulose Membrane film

- 7Film Applicator Coating colorants film application

- 8Application of laboratory coater on release paper with glue [video demonstration]

- 9Importance of powder coatings curing degree and detection method

- 10Epoxy-polyethylene (PE) Resin thick coatings Anticorrosive coatings: innovative protection solutions

Standard

TBJ-X5-DJ1

TBJ-X5-DJ1