LANDTEK TM8812C Ultrasonic Thickness Gauge split Ultrasonic Thickness Gauge

SELANDTEK TM8812C Ultrasonic Thickness GaugeSPEC

LANDTEK TM8812C Ultrasonic Thickness GaugeDetails

LANDTEK TM8812C Ultrasonic Thickness GaugePacking list

- SKU

- NB003878

- Measuring range

- 1.2~200mm

- Probe frequency

- 5MHz

- Probe style

- Split probe

- Probe diameter

- Ф8mm

- Lower limit of pipe measurement

- F8 * 2mm

- Measurement error

- ±(0.5%H+0.2)mm

- Display resolution

- 0.01mm

- unit system

- mm

- Sound speed range

- 500~9000m/s

- Display

- 4-Position 10mm LCD

- Operating language

- Chinese

- Application software

- without

- Operating Temperature

- 0~40℃

- Relative Humidity

- <85% RH

- Power

- 4 * 7 battery

- Host size

- 120*62*30mm

- Weight

- Approx. 164g (without battery)

- Application

- Film thickness measurement and corrosion measurement of boiler oil storage tanks, pipes, pipes, plates, forgings, flanges, hulls, decks, tracks, machined parts, etc. in petrochemical industry, shipbuilding industry, automobile manufacturing industry, power station, and machine manufacturing

Product Description

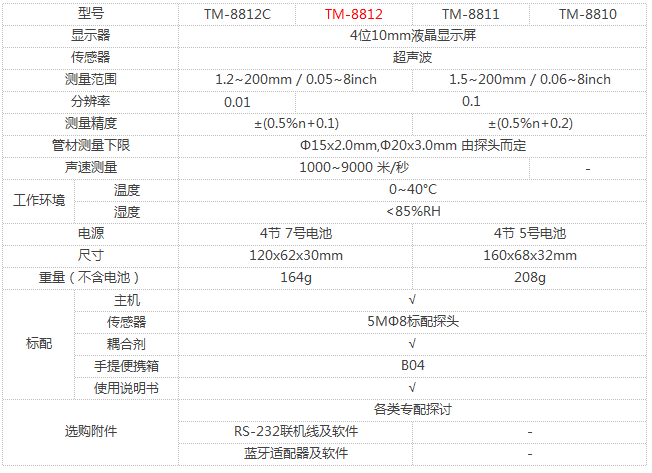

LANDTEK TM8812 series precision ultrasonic Thickness Gauge, including TM8812 and TM8812C, is a practical split-type precision ultrasonic Thickness Gauge, adopting new high-performance, low-power consumption microprocessor technology, with a resolution of 0.1mm/0.01 mm, the measuring range is 1.2~200mm. TM8812 Precision Ultrasonic Thickness Gauge can be used to measure the thickness of various pipes and pressure vessels in production equipment, and can also accurately measure various plates and various processed parts.

Application

LANDTEK TM8812 series precision ultrasonic Thickness Gauge is suitable for boiler oil storage tanks, pipes, pipes, plates, forgings, flanges, hulls, decks, rails in petrochemical industry, shipbuilding industry, automobile manufacturing industry, power station, machine manufacturing , thickness measurement and corrosion measurement of machined parts, etc. This instrument can be used to measure the thickness of most materials that can transmit ultrasonic waves, such as: metal, ceramics, materials, nylon, glass, etc.

Real picture of Thickness Gauge

Thickness Gauge Features

*LANDTEK TM8812C precision ultrasonic Thickness Gauge adopts high performance and low power consumption microprocessor technology.

* Automatic memory material code and sound velocity value, easy to use.

* With coupling status prompt function.

* Automatic shutdown, manual shutdown function.

* Precise ultrasonic Thickness Gauge TM8812 series uses RS-232C data line output and PC for data collection, processing, analysis and printing functions.

* In addition, there is an option for Bluetooth data output.

* It has strong transmitting power and high broadband receiving sensitivity. It can adapt to probes of different frequencies, so it can measure heavily corroded rough surfaces, painted surfaces, and even some gray cast irons.

* Digital display, no parallax.

Standard configuration

1. Precision Ultrasonic Thickness Gauge TM8812/TM8812C.......... 1 set

2. 5MФ8 sensor......1pc

3. Coupling agent........1 piece

4. Portable box........1

5. Instruction manual........1 copy

optional accessories

1. 6MФ6 small diameter sensor: Measuring range (steel): 1.0-50.0mm Allowable contact temperature 0~50℃

2. 5MФ12 high temperature sensor: Measuring range (steel): 4.0-100.0mm Allowable contact temperature 60~300℃

3. Surface sensor

4. USB, RS232C communication cable and software

5. Bluetooth communication and software

Comparison of this series of precision ultrasonic Thickness Gauges

Optional probe [need to be purchased separately]

- 1JJF 1224-2009《Calibration Specification for Reinforced Concrete Covermeter and Floorslab Thickness Tester》

- 2JJF 1126-2004《Calibration Specification for Ultrasonic Thickness Instruments》

- 3JB/T 11604-2013《Non-destructive testing instruments.Ultrasonic thickness gauge》

- 4ASTM E797-2021《Standard Practice for Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact Method》

- 5GB/T 11344-2008《Non-destructive testing - Practice for measuring thickness by ultrasonic pulse-echo contact method》

- 6JJF 1126-2004《Ultrasonic Thickness Gauge calibrating specification》

- 7ZB N 77001-1989《General Technical Conditions for Ultrasonic Thickness Gauge》

TM8812C

TM8812C